Novel automatic packaging intelligent garbage can

A garbage can, automatic technology, applied in the field of garbage cans, can solve the problems of insecure sealing strength, uneven use of garbage bags, unsealable garbage bags, etc., to achieve simple and reasonable structure, stable and reliable force, and smooth packing closing surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

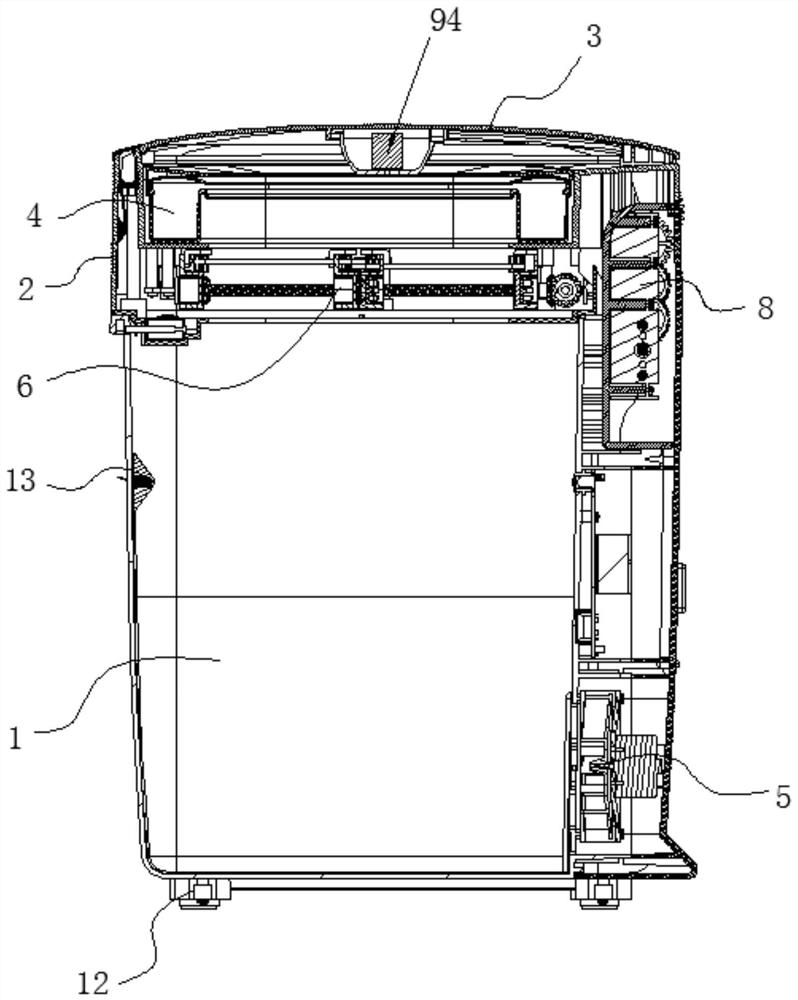

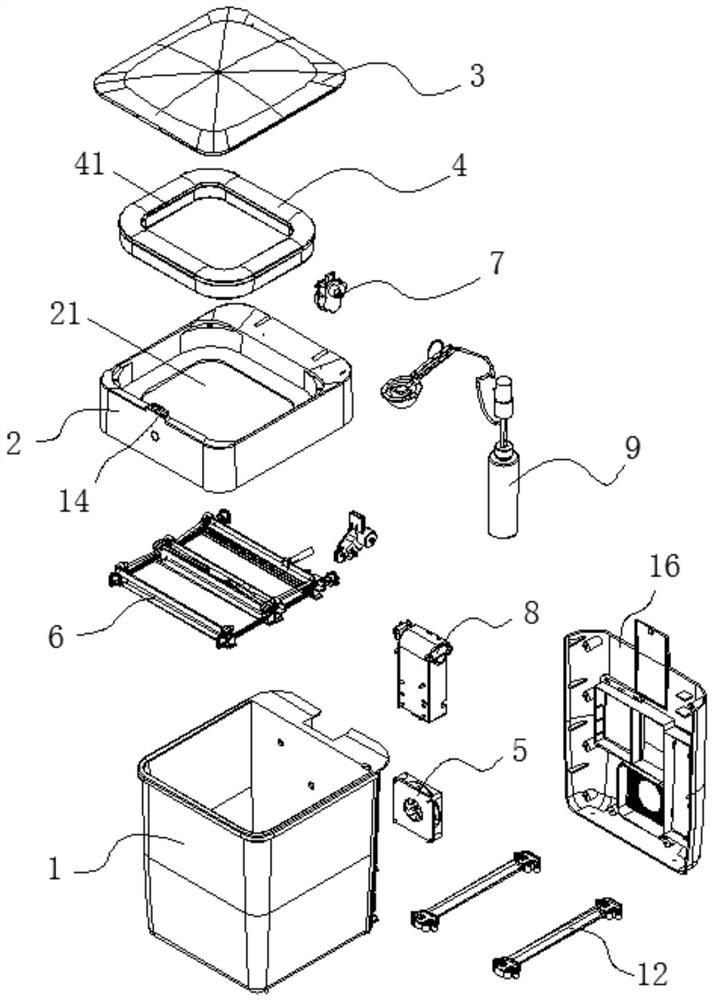

[0054] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention provides a new type of automatic packing intelligent trash can, including a barrel body 1, a middle cover 2, a top cover 3, and a garbage bag box 4 for storing garbage bags, and the middle cover 2 is installed on the barrel body 1, the top cover 3 is rotatably installed on the middle cover 2, the lower end of the barrel body 1 is provided with an exhaust fan 5 for negative pressure bagging, and the middle cover 2 is equipped with an automatic closing thermoplastic sealing and cutting mechanism 6, etc. part.

[0055] Each component of this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0056] Such as Figure 1 to Figure 3 As shown, the garbage bag box 4 is arranged in a ring shape and is installed at the middle cover opening 21 of the middle cover 2. The inside of the garbage bag box 4 is provided with a circle of bag storage space, and the inner...

Embodiment 2

[0074] Embodiment 2 of the present invention provides a new type of automatic packing intelligent trash can. The trash can in Embodiment 2 has the following functions and structures added on the basis of Embodiment 1 above.

[0075] As preferably, in order to enable the top cover to be turned over automatically, such as Figure 13 As shown, a top cover driving device 7 for driving the top cover 3 to open and close can be added between the top cover 3 and the middle cover 2, and the top cover driving device 7 can include a top cover driving motor 71 and a top cover driving gear box 72, the top cover driving motor 71 can be connected with the top cover 3 through the top cover driving gear box 72, and the top cover driving motor 71 can drive the gears in the top cover driving gear box 72 to rotate so as to drive the top cover 3 to turn over.

[0076] As preferably, in order to enable the middle cover to be turned over automatically, such as Figure 4 As shown, an additional midd...

Embodiment 3

[0078] Embodiment 3 of the present invention provides a new type of automatic packing intelligent trash can. The trash can in Embodiment 3 has the following functions and structures on the basis of Embodiment 1 above.

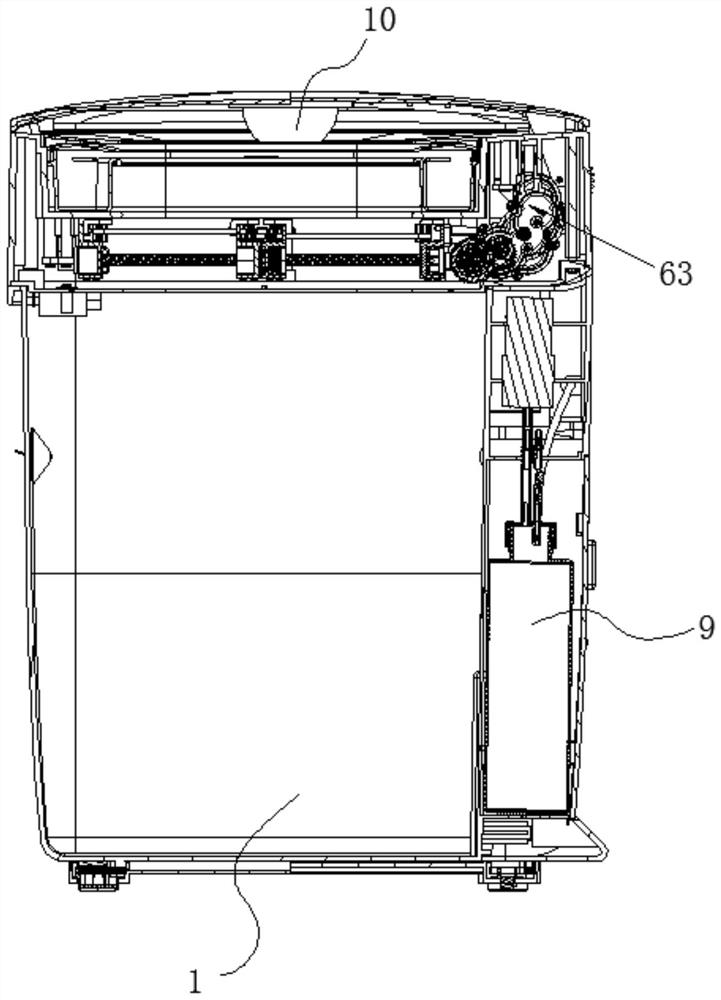

[0079] Such as Figure 4 with Figure 14 As shown, the trash can can also be provided with an automatic spray disinfecting device 9, which can include a disinfectant bottle 91, an air pump motor 92, an infusion tube 93 and a sprayer 94, and the disinfectant bottle 91 is installed in the barrel body 1 At the back, the gas pipe of the air pump motor 92 is connected with the disinfectant bottle 91, and the disinfectant bottle 91 is connected with the sprayer 94 through the infusion tube 93, and the sprayer 94 is installed on the top cover 3 and / or on the inner wall of the barrel body 1.

[0080] Such as Figure 15 As shown, the sprayer 94 can include a spray sealing cover 941, water-absorbing cotton 942 and atomizing sheet 943, the inlet of the spray sealing cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com