Steel structure section generation method and device, computer equipment and storage medium

A steel structure and cross-section technology, applied in the direction of configuration CAD, design optimization/simulation, special data processing applications, etc., can solve problems such as low efficiency, cumbersome modeling process, etc., to improve efficiency, rapid modeling, and solve the process cumbersome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

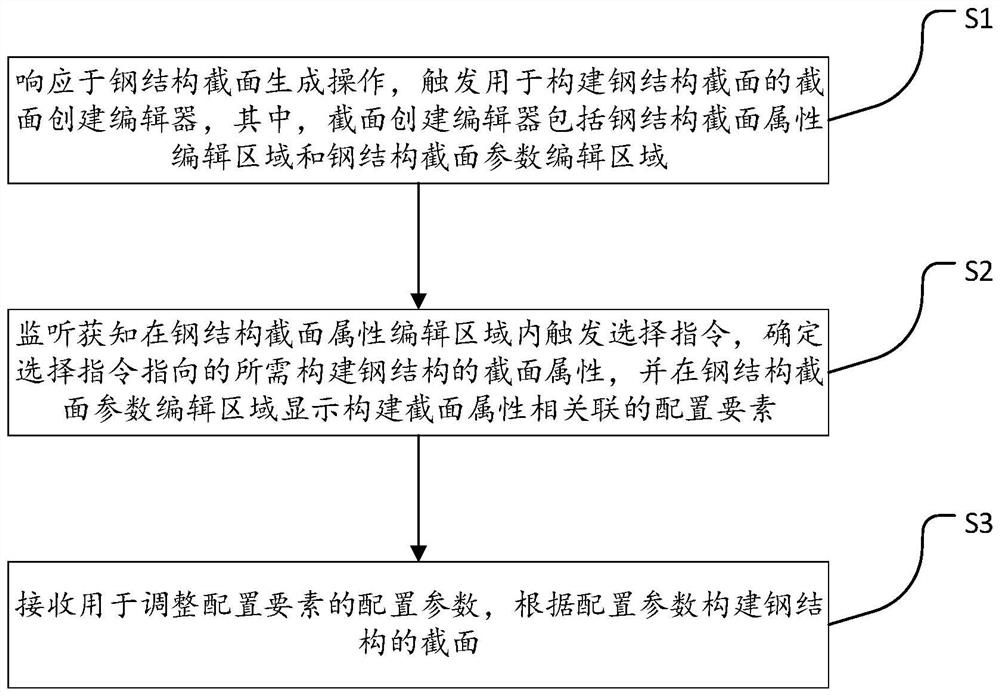

[0032] Embodiment 1 of the present invention provides a method for generating a section of a steel structure, please refer to figure 1 , figure 1 It is a schematic flowchart of a method for generating a section of a steel structure provided in an embodiment of the present application, and the method specifically includes the following steps S1 to S3.

[0033] Step S1: In response to the steel structure section generation operation, trigger a section creation editor for constructing the steel structure section, wherein the section creation editor includes a steel structure section attribute editing area and a steel structure section parameter editing area.

[0034] The steel structure cross-section generation method provided by this application can be integrated in other software as one of the functions of the software. For example, this application can be used as a built-in function of engineering cost software and model generation software. In addition, the scheme of this app...

Embodiment 2

[0070] Based on the steel structure cross-section generation provided in the above-mentioned embodiment 1, a steel structure cross-section generation device is provided in the second embodiment of the present application. The corresponding technical feature details and corresponding technical effects can refer to the above-mentioned first embodiment. In this No more details will be given in the embodiments. Figure 7 The structural block diagram of the steel structure section generating device provided for the second embodiment of the present invention, as Figure 7 As shown, the device includes: a first construction module 701, configured to trigger a section creation editor for constructing a steel structure section in response to a steel structure section generation operation, wherein the section creation editor includes a steel structure section attribute editing area and Steel structure section parameter editing area; the first determination module 702 is used to monitor ...

Embodiment 3

[0086] This embodiment also provides a computer device, such as a smart phone, a tablet computer, a notebook computer, a desktop computer, a rack server, a blade server, a tower server, or a cabinet server (including an independent server, or A server cluster composed of multiple servers), etc. Such as Figure 8 As shown, the computer device 80 in this embodiment at least includes but is not limited to: a memory 801 and a processor 802 that can be communicatively connected to each other through a system bus. It should be pointed out that, Figure 8 Only computer device 80 is shown with components 801-802, but it should be understood that implementing all of the illustrated components is not a requirement and that more or fewer components may instead be implemented.

[0087]In this embodiment, the memory 801 (that is, a readable storage medium) includes a flash memory, a hard disk, a multimedia card, a card-type memory (for example, SD or DX memory, etc.), random access memor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com