Electric vehicle front fork with damping function

A technology for electric vehicles and front forks, which is applied in the field of electric vehicles, can solve the problems of easy breakage, wear of the fixed sleeve and fork shoulder, poor shock absorption effect, etc., and achieve the effects of not easy to deform, good support effect, and good bending resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

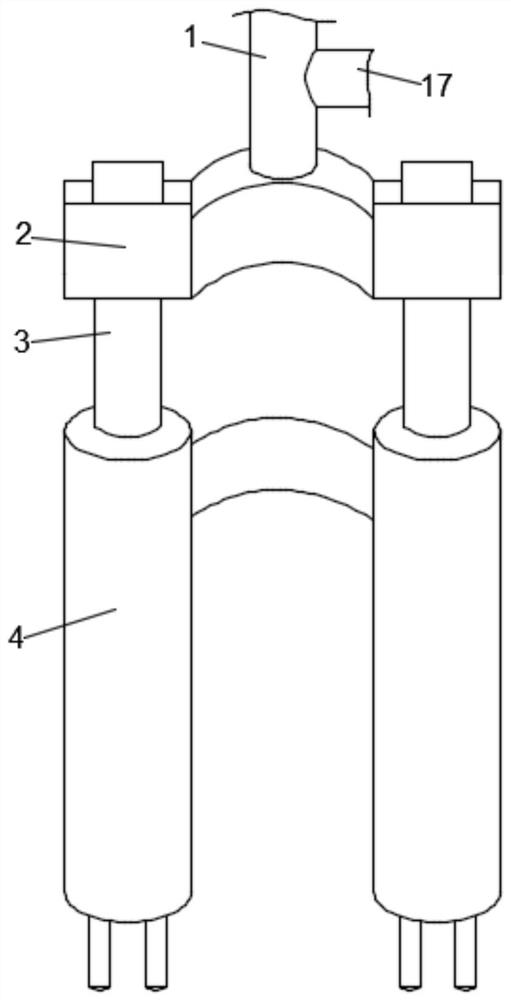

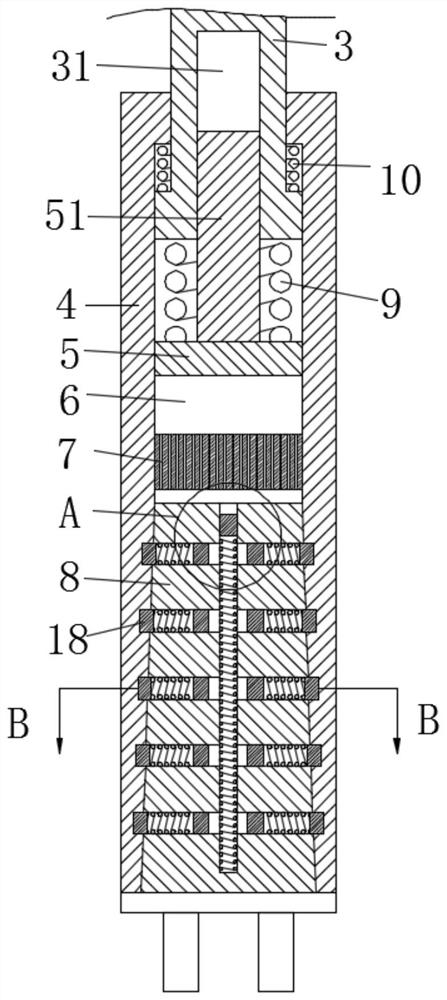

[0029] Such as Figure 1-7 As shown, in this embodiment, a kind of electric vehicle front fork with shock absorbing function is provided, comprising a shoulder 2 and a shock absorbing assembly installed at both ends of the shoulder 2, and the middle part of the shoulder 2 is far away from the shock absorbing assembly. Fixed shaft 15 is installed on one side, and fixed shaft 15 is rotated and installed in the inside of fixed sleeve 1, and fixed sleeve 1 is fixed on the vehicle body, and fixed shaft 15 is connected with handlebar, and handlebar controls fixed shaft 15 to rotate;

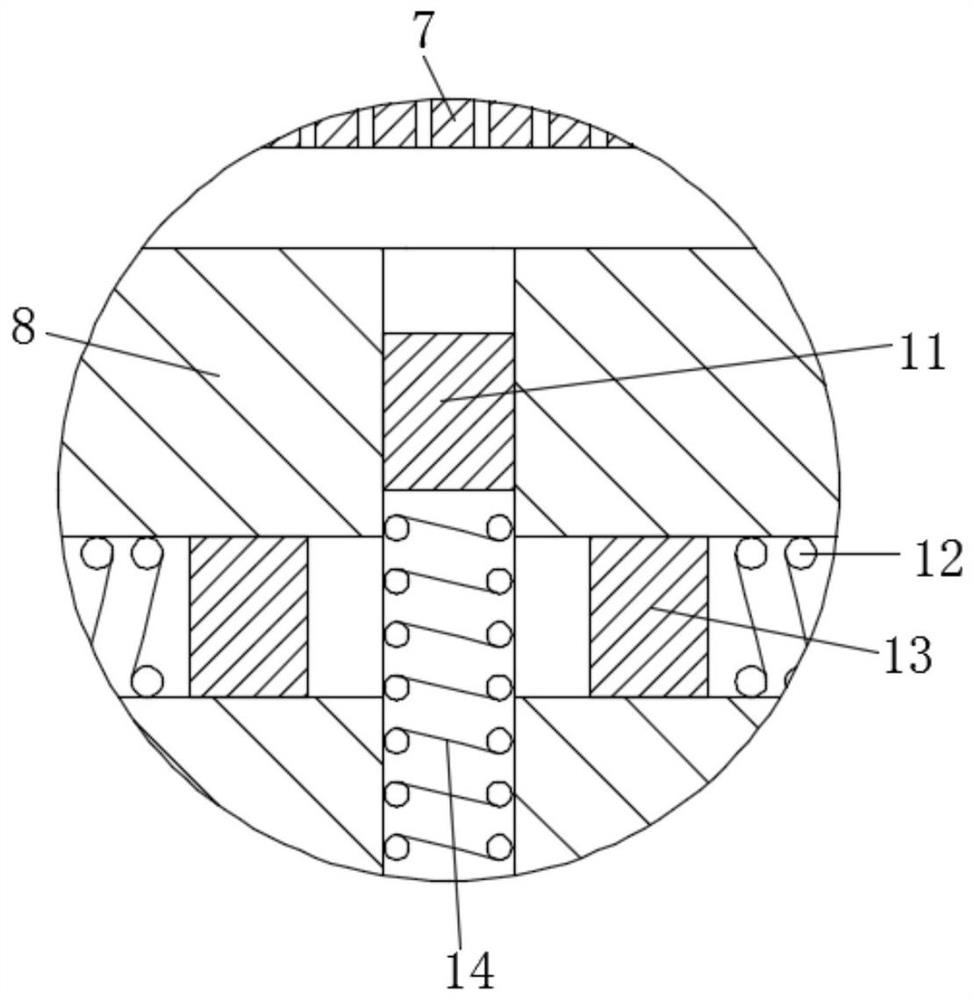

[0030] The shock absorbing assembly includes an inner shaft 3 mounted on the prong 2 and a casing 4 sleeved outside the inner shaft 3, a bridge is installed between the two casings 4, and the bridge is used to support the two casings 4 , to prevent its relative position from changing, the bottom of the housing 4 is plugged with a bottom shaft 8, the bottom shaft 8 is a truncated cone, the inner wall of...

Embodiment 2

[0032] combine Figure 5-6 , on the basis of Embodiment 1, the following embodiment is proposed: the fixed shaft 15 is inserted into the inside of the fixed sleeve 1, the fixed sleeve 1 is fixed with the electric vehicle body, and one side of the fixed sleeve 1 is installed with a side Column 17, side column 17 is the medium that is used for being connected with car body, and described fixed shaft 15 is provided with a plurality of steps, and each described step is a conical surface, and the fixed shaft 15 conical surfaces and fixed sleeve 1 are provided with There are gaps, and several uniformly arranged rollers 16 are installed at each gap, and the rollers 16 are circumferentially arranged on the cone surface, and the rollers 16 on the fixed shaft 15 are in contact with the inclined surface on the inner wall of the fixed sleeve 1, so that the fixed shaft 15 and the fixed shaft are in contact with each other. The rotation between the sleeves 1 is smoother, and the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com