Sliding block anti-falling locking device of press machine

A locking device and press technology, which is applied in the field of presses, can solve the problems of inconvenient maintenance and repair of presses or inconvenient mold repairs on the press, damage to sliders and related parts, and large falling amount of sliders, so as to achieve flexible and smooth coordination and shortening. Action time, the effect of reducing collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

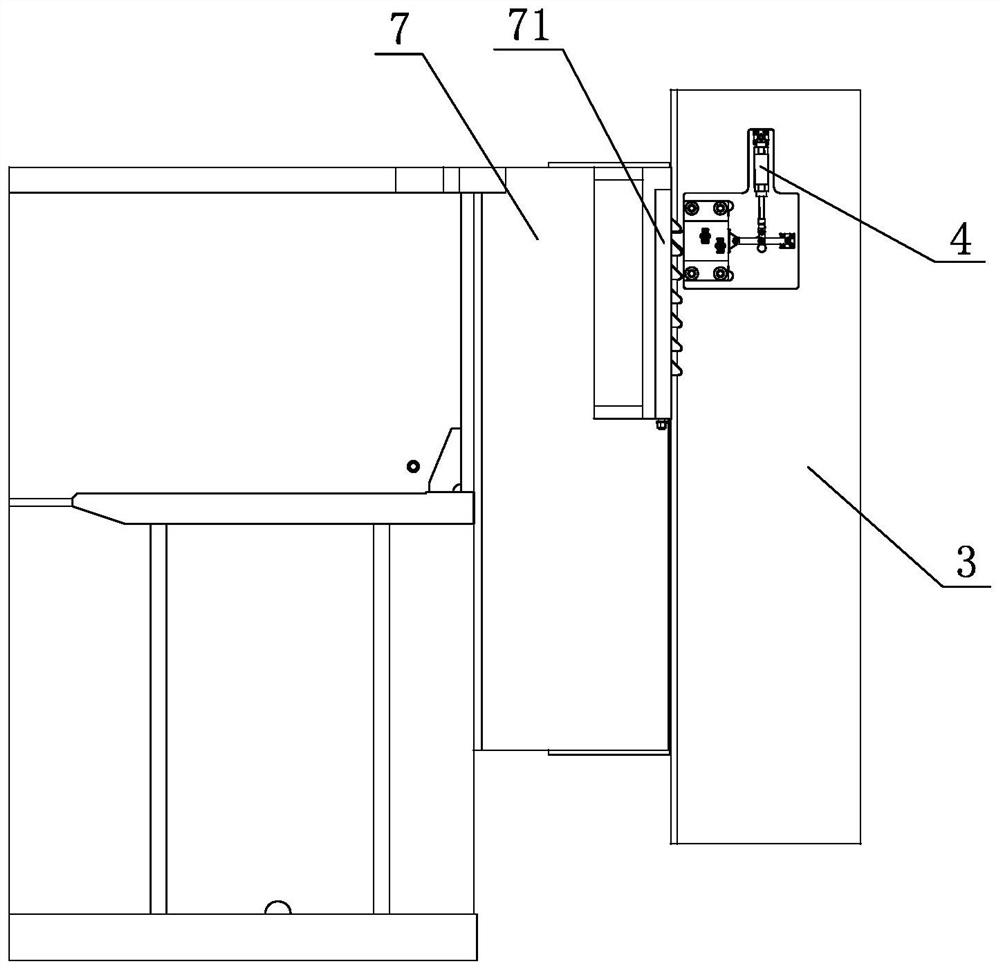

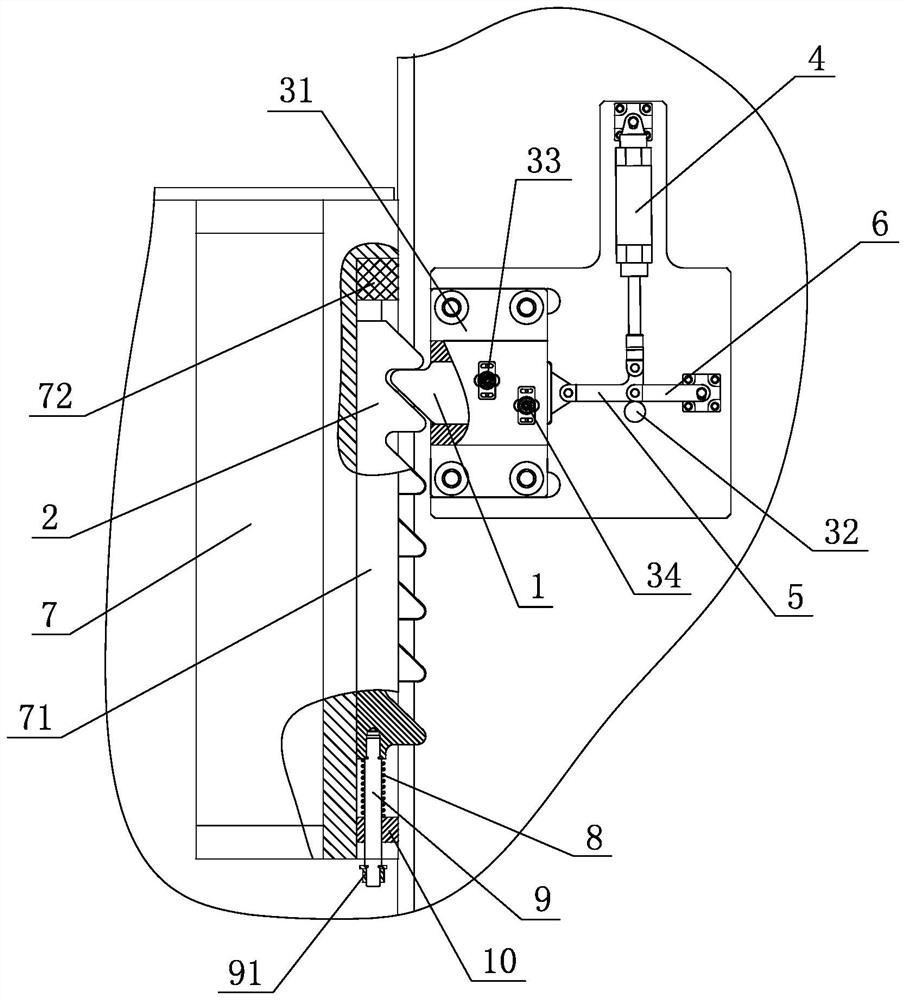

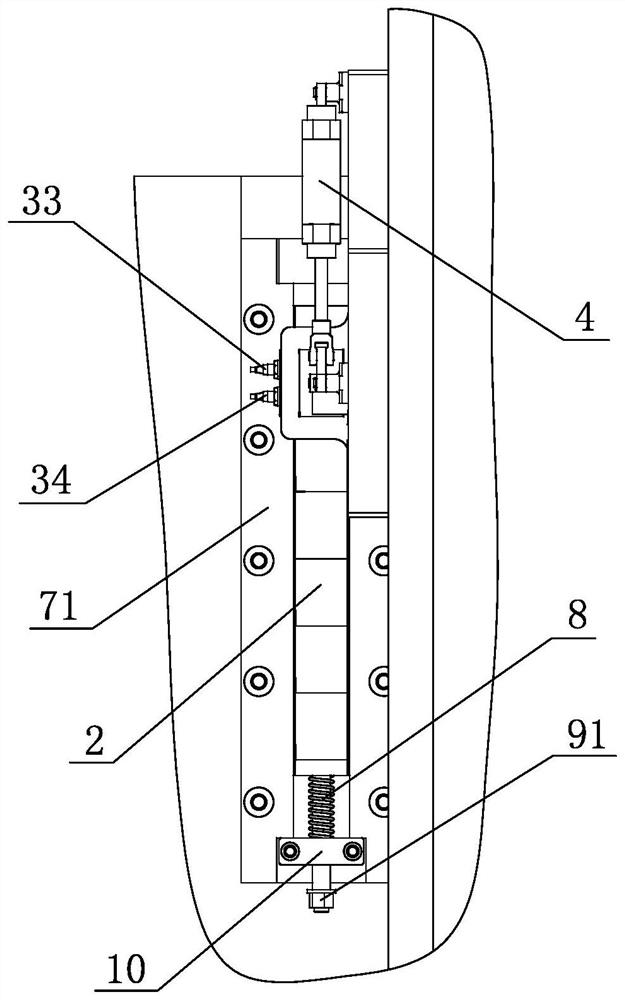

[0024] As shown in the figure, a sliding block anti-drop locking device of a press includes a lock tongue 1 and a rack 2, the lock tongue is arranged on the frame column 3 of the press machine, and the frame column 3 is provided with a lock tongue driving mechanism and the deadbolt position detection mechanism, the deadbolt driving mechanism includes a cylinder 4, an L-shaped connecting rod 5 and a straight connecting rod 6, the cylinder 4 is fixed on the frame column 3, and one end of the L-shaped connecting rod 5 is connected to the piston rod of the cylinder 4 The ends are hinged, the other end of the L-shaped connecting rod 5 is hinged with the rear end of the dead bolt 1, one end of the straight connecting rod 6 is hinged with the turning point of the L-shaped connecting rod 5, and the other end of the straight connecting rod 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com