Jewelry and surface treatment method thereof

A surface treatment and jewelry technology, applied in clothing, application, jewelry, etc., can solve the problem that enamel cannot show crack effect, affect the visual effect of jewelry products, etc., achieve uniform crack texture, natural crack effect, and good safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

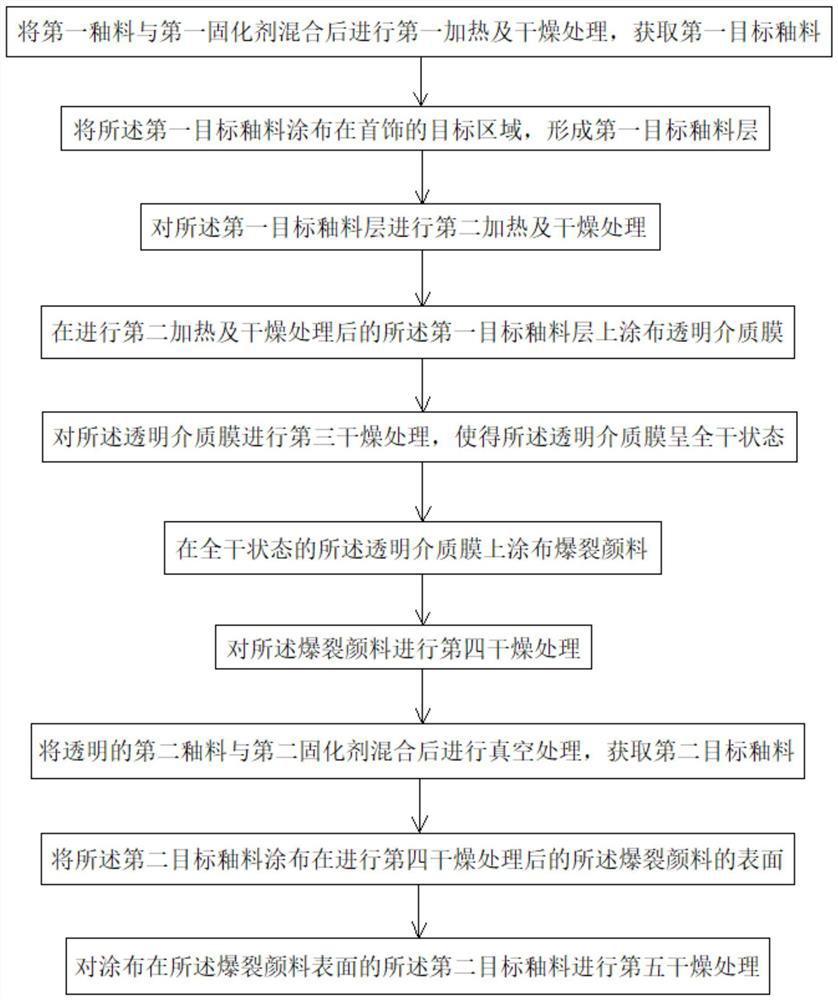

[0038] Such as figure 1 Shown, the surface treatment method of the jewelry that the present invention proposes, comprises the following steps:

[0039] (1) Mixing the first glaze and the first curing agent and then performing the first heating and drying treatment to obtain the first target glaze. Wherein, the function of the first curing agent is to promote the solidification and hardening of the first target glaze. If the first curing agent is lacking, the first target glaze cannot be solidified and hardened after being applied to the surface of the jewelry.

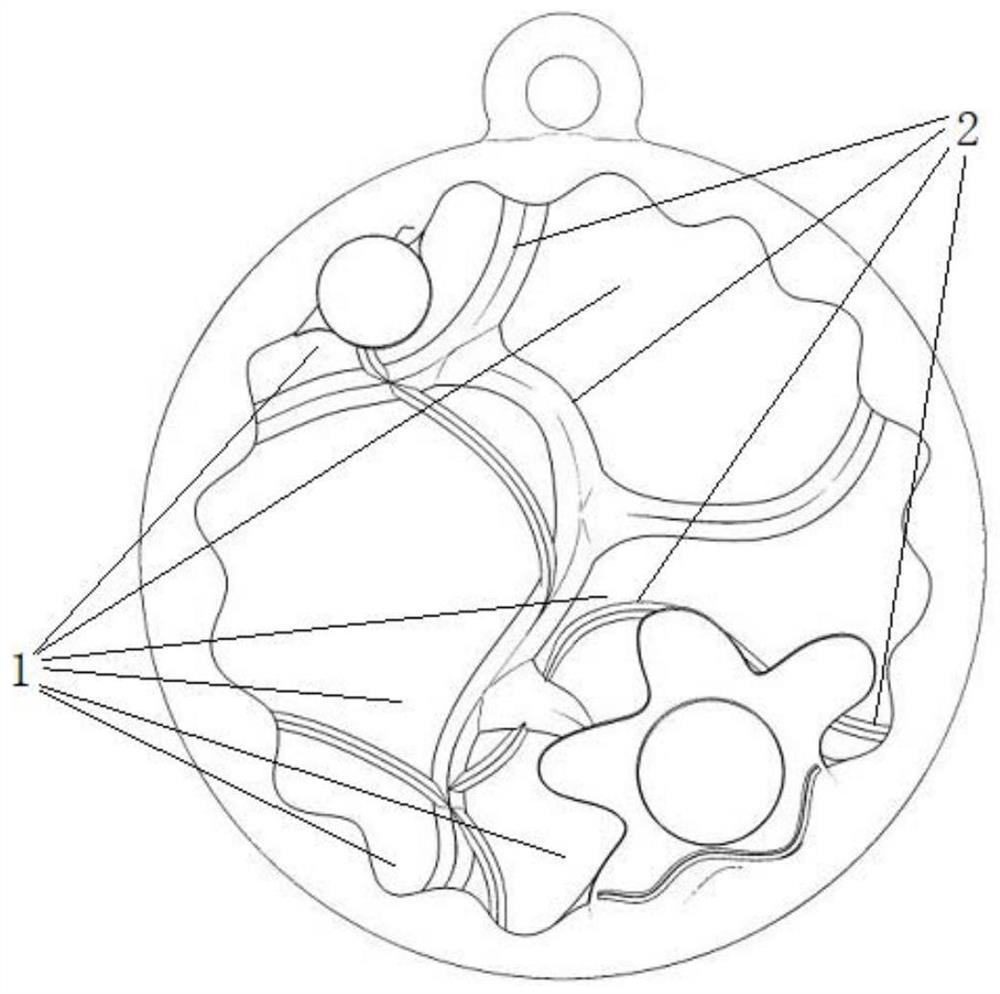

[0040] (2) Coating the first target glaze on the target area 1 (colored area) of the jewelry to form the first target glaze layer. Wherein, the first target glaze can be coated on the target area 1 of the jewelry by mechanical or manual means.

[0041] (3) Carrying out a second heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com