Method for preparing asparagus ferment from juicing residues

An asparagus and residue technology, which is applied in the field of asparagus enzyme preparation, can solve the problems of poor utilization efficiency, low added value, waste of resources, etc., and achieves the effects of small investment in equipment, lightening of burden, and refreshing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

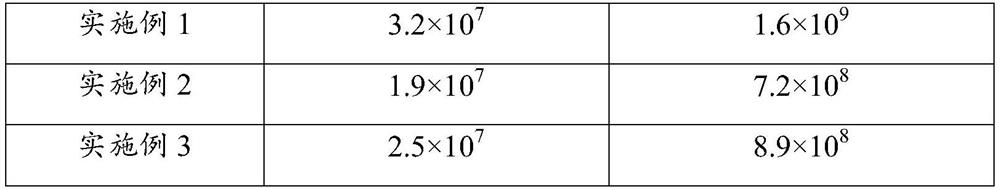

[0045] Example 1

[0046] Method for preparing asparagus enzymes using juice residue, including the following steps:

[0047] (1) Raw material treatment: take fresh asparagus, use pure water cleaning three times;

[0048] (2) Grout: Add a pectin enzyme with a weight of 0.10 ‰, using a broken wall;

[0049] (3) Juice: Pour the asparagus pulp into the juicer, juice, collect asparagus juice and asparagus slag;

[0050] (4) Filtering: Asparagus juice will be collected, filter with 40 mesh screen, collect small amount of residue in asparagus juice;

[0051] (5) Addition: Collect two asparagus residues, add water than 1g: 7 mL, and 5 g of glucose is added to the total amount of the material is adjusted according to the liquid ratio;

[0052](6) Sterilization: After loading flask deployment of a good material for 30min at 95 deg.] C, sterilized;

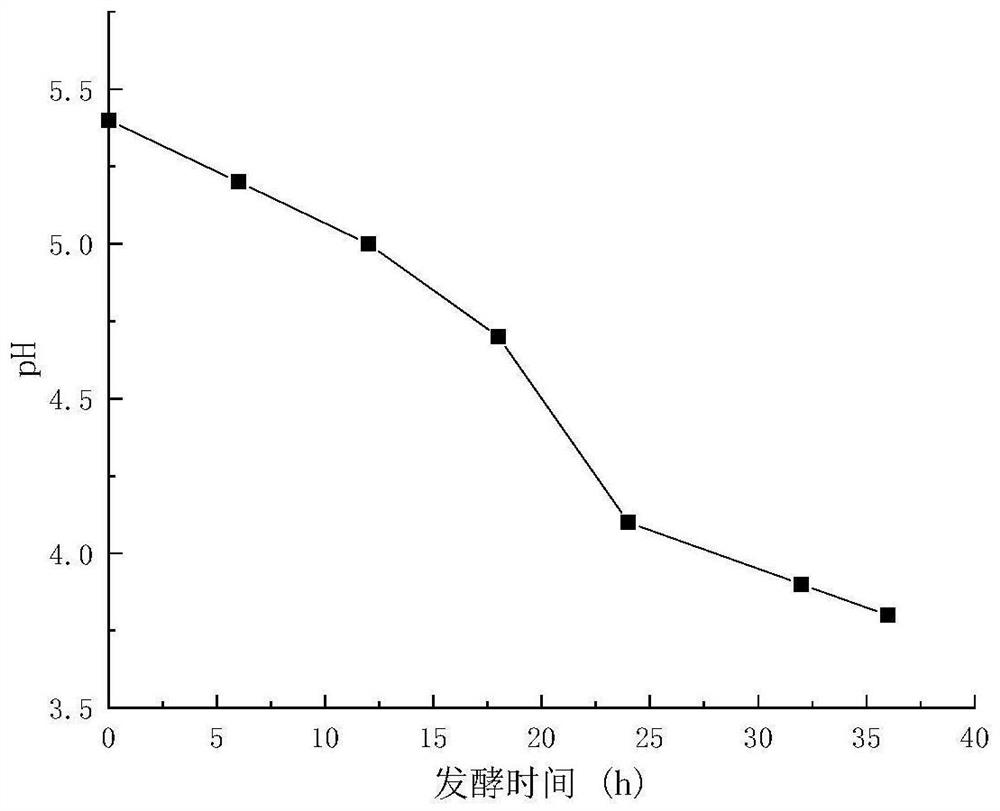

[0053] (7) Fermentation: after sterilization was cooled to room temperature, as recommended by the commercial lactobacillus inoculum was adde...

Example Embodiment

[0057] Example 2

[0058] A method for the preparation of asparagus juice residues using the enzyme, comprising the steps of:

[0059] (1) Raw material treatment: Fresh asparagus, washed three times with pure water;

[0060] (2) beating: 0.08 ‰ by weight was added pectinase asparagus using a pulping machine broken;

[0061] (3) juice: The slurry was slowly poured into the asparagus juice, a juice, asparagus juice were collected slag and asparagus;

[0062] (4) Filter: asparagus juice collected using 40 mesh screens to collect a small amount of asparagus juice present in the residue;

[0063] (5) formulation: The residue collects two asparagus according to liquid ratio 1g: Add 10mL of water ratio, the total volume of 100mL per glucose was added 8g, according to liquid ratio constant volume;

[0064] (6) Sterilization: After loading flask deployment of a good material for 30min at 92 deg.] C, sterilized;

[0065] (7) Fermentation: after sterilization was cooled to room temperature,...

Example Embodiment

[0069] Example 3

[0070] A method for the preparation of asparagus juice residues using the enzyme, comprising the steps of:

[0071] (1) Raw material treatment: Fresh asparagus, washed three times with pure water;

[0072] (2) beating: 0.08 ‰ by weight was added pectinase asparagus using a pulping machine broken;

[0073] (3) juice: The slurry was slowly poured into the asparagus juice, a juice, asparagus juice were collected slag and asparagus;

[0074] (4) Filter: asparagus juice collected using 40 mesh screens to collect a small amount of asparagus juice present in the residue;

[0075] (5) formulation: The residue collects two asparagus according to liquid ratio 1g: adding water ratio 6mL per total volume of 100mL was added 3g of glucose, according to liquid ratio constant volume;

[0076] (6) Sterilization: After loading flask deployment of a good material for 30min at 93 deg.] C, sterilized;

[0077] (7) Fermentation: after sterilization was cooled to room temperature, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com