Device and method for sampling metal sheath of ultrahigh-voltage metal sheath cable

A metal sheath and sampling device technology, which is applied to sampling devices, measuring devices, mechanical devices, etc., can solve the problems of sampling failure to meet standard requirements, damage to cable insulation cores, and reduced cable service life, and achieves a simple structure. , easy to use, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

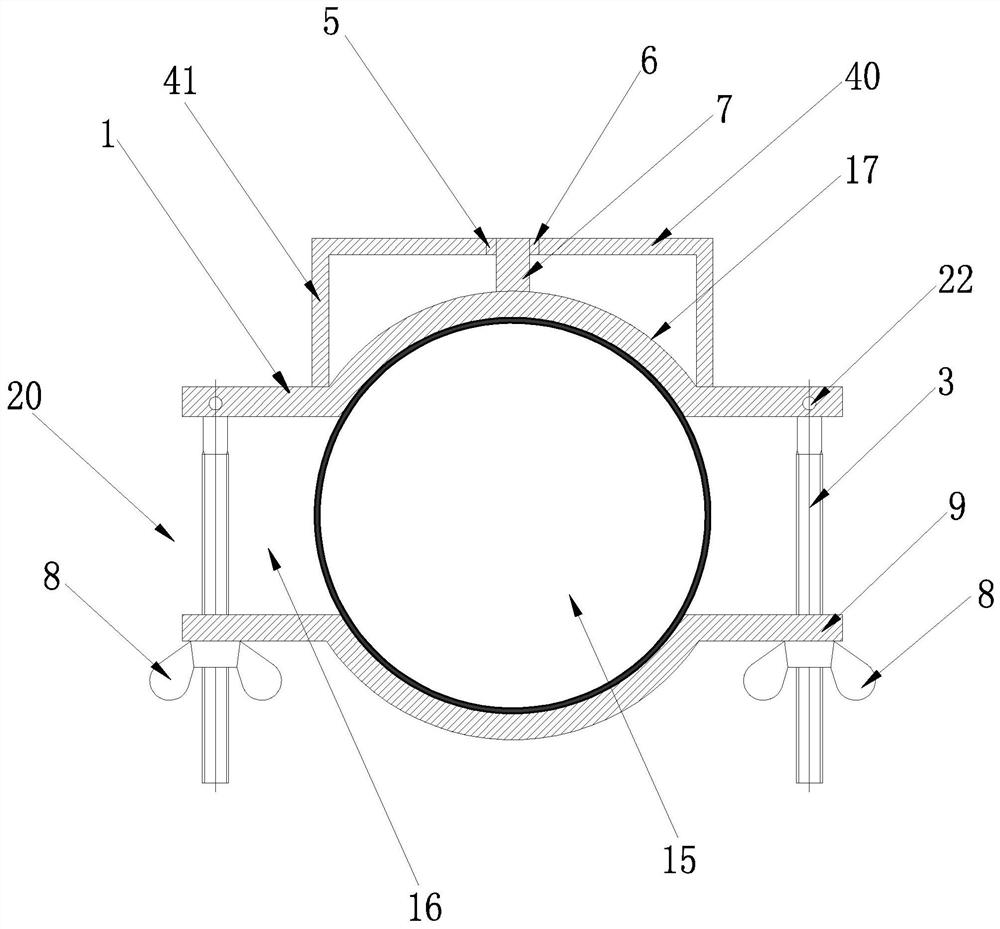

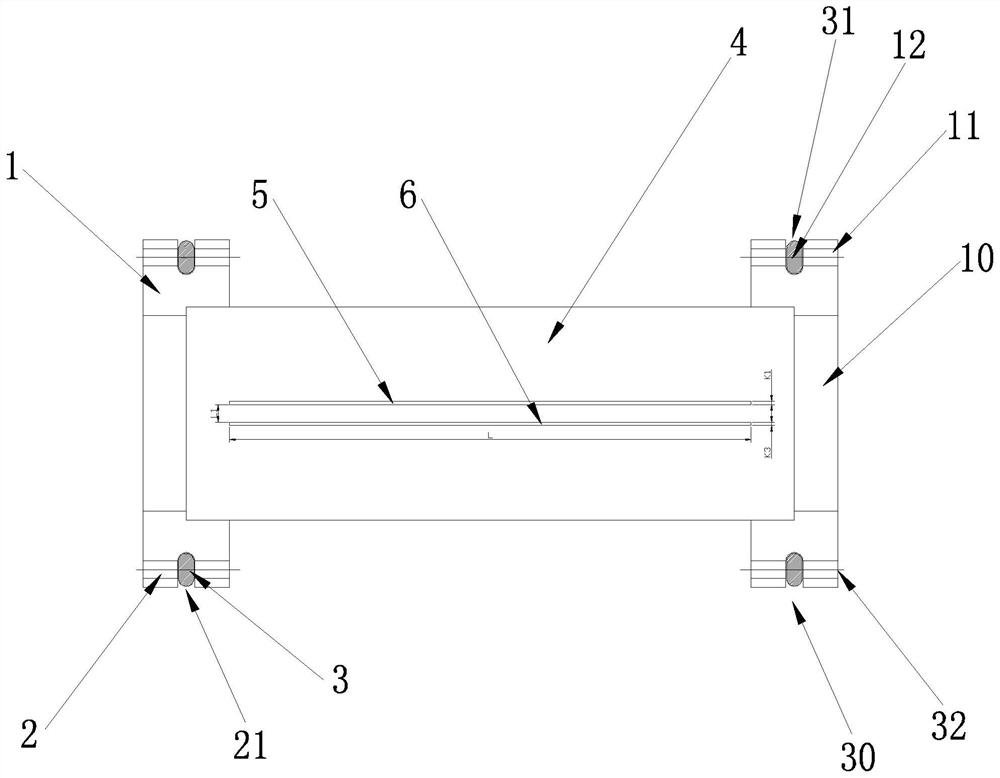

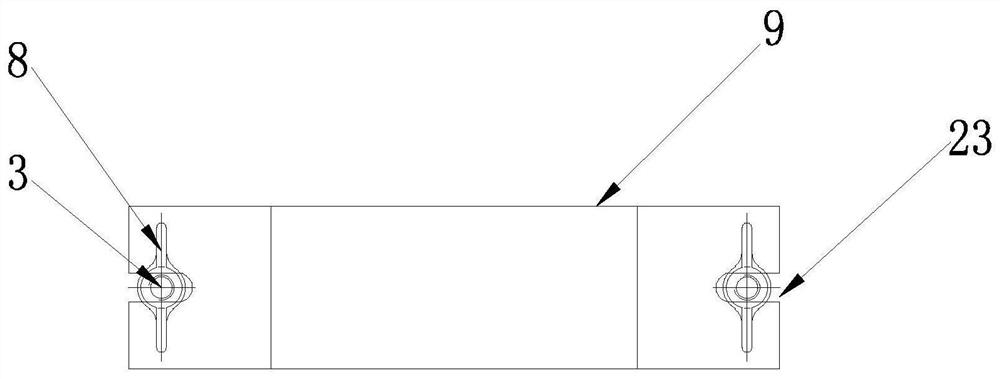

[0030] Such as Figure 1-4 As shown, this embodiment discloses a metal sheath sampling device for ultra-high voltage metal sheathed cables, including a fixed platform 4, an upper left splint 1 and an upper right splint 10 respectively installed on both sides of the fixed platform 4; The left guide slot 5 and the right guide slot 6 are symmetrically arranged in the length direction; a suspended fixed bracket 7 is arranged between the left guide slot 5 and the right guide slot 6; the left upper splint 1 is correspondingly installed with a left lower splint 9; 1 and the left lower splint 9 are locked through the left connecting mechanism 20, and the bottom of the right upper splint 10 is correspondingly equipped with a right lower splint 14; between the right upper splint 10 and the right lower splint 14 is locked through the right connecting mechanism 30, and the left upper splint 1 Between the left lower clamping plate 9 and the right upper clamping plate 10 and the right lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com