Organic fertilizer production and fermentation equipment for improving soil

A technology for improving soil and fermentation equipment, applied to specific-purpose bioreactors/fermenters, biochemical equipment and methods, bioreactor/fermenter combinations, etc., which can solve the problem of low flow rate up and down and temperature drop Slow, affect the quality of finished products and other issues, to achieve the effect of increasing the cooling rate, preventing the water temperature from rising, and ensuring the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

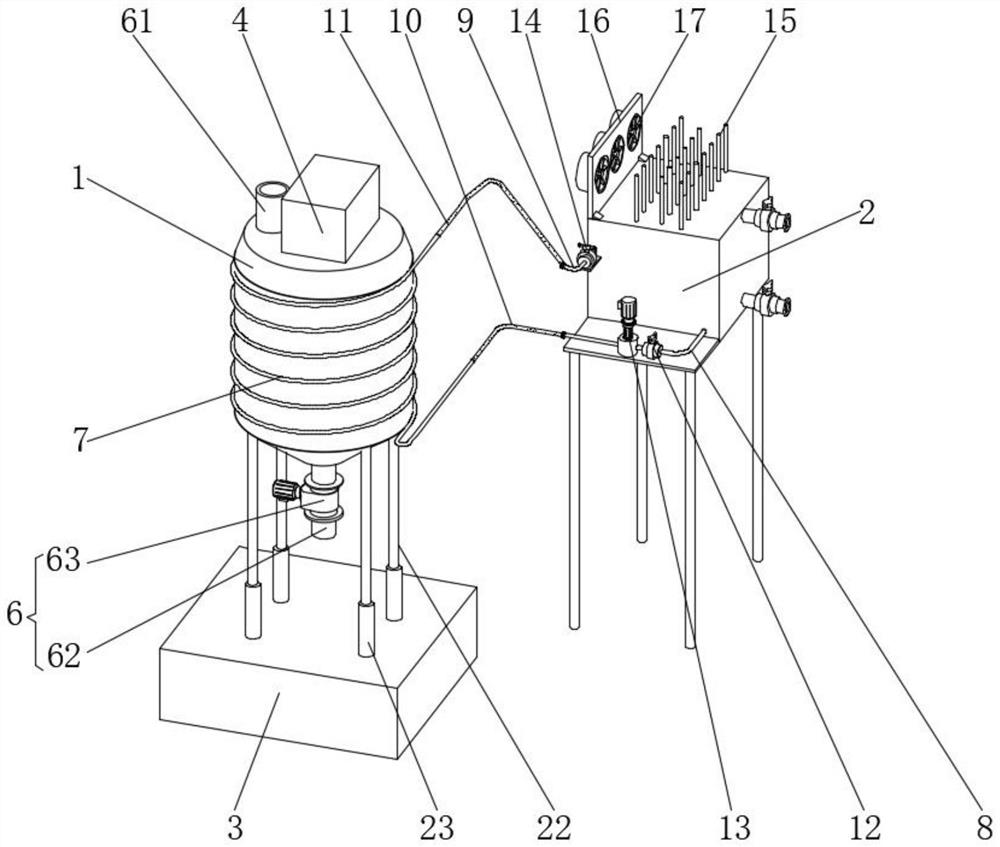

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0038] Such as Figure 1-Figure 6As shown, the soil-improving organic fertilizer production fermentation equipment includes a fermentation tank body 1, a water tank 2, a bottom shell 3, a box body 4, a stirring drive mechanism 5, a feeding and discharging mechanism 6, and a reciprocating drive mechanism 24, and the box body 4 is bolted. On the top of the fermenter body 1, the surface of the fermenter body 1 is fixedly provided with a cooling pipe 7, the front of the water tank 2 is respectively connected with a delivery pipe 8 and a return pipe 9, and the two ends of the cooling pipe 7 are respectively connected with a first flexible pipe. Pipe 10 and second hose 11, the other end of the first hose 10 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com