Automatic packaging mechanism of intelligent garbage can and garbage can

A garbage can, automatic technology, applied in the direction of garbage cans, garbage collection, packaging, etc., can solve the problems of large size of the connection end, twisted and slipped transmission belt, etc., to achieve improved stability and reliability, good synchronization, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

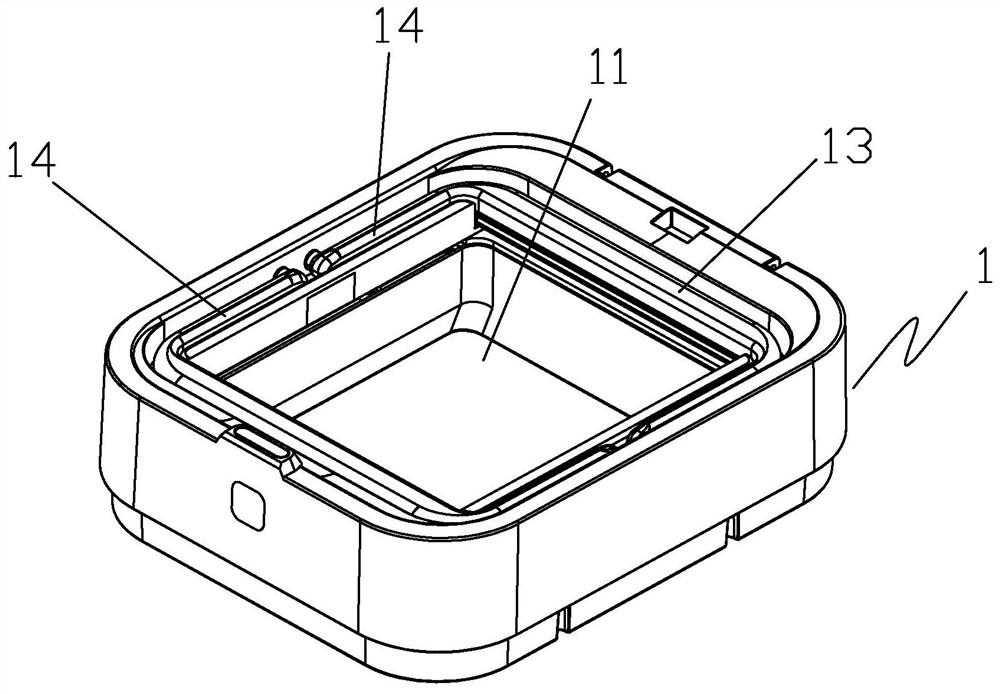

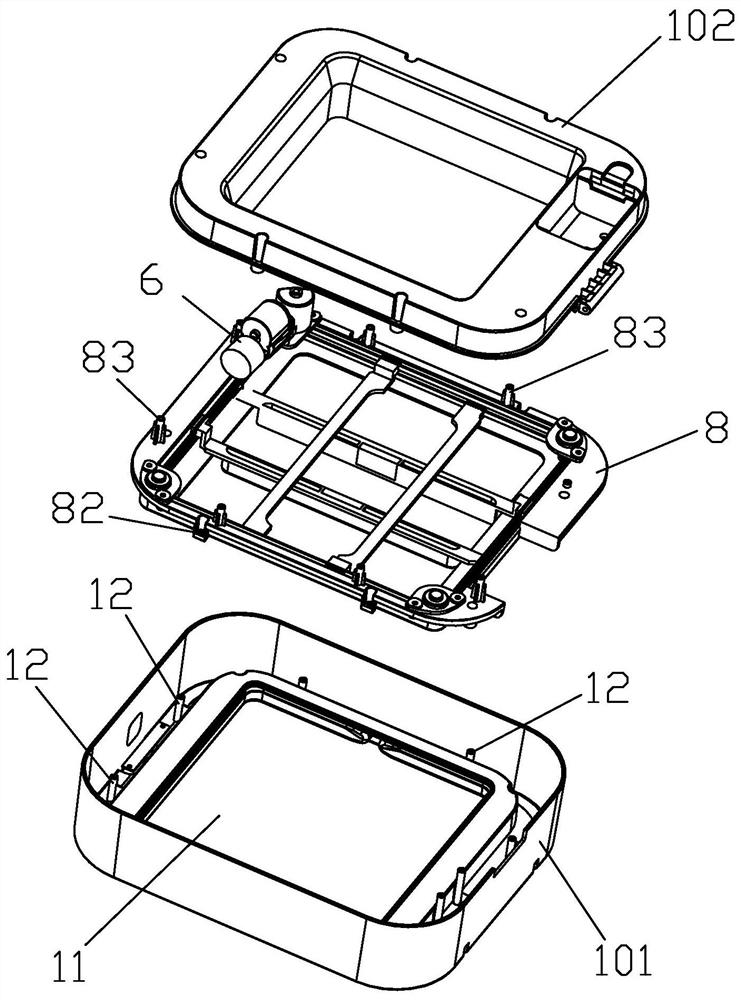

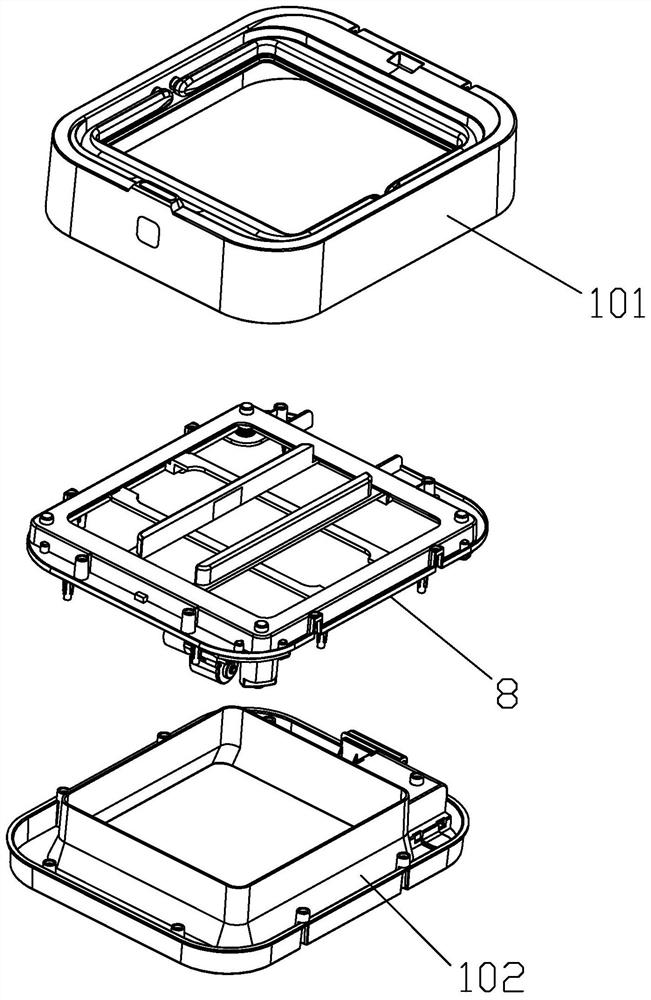

[0036] Such as Figure 1-14As shown, a trash can includes a barrel body 10 and a seat body 1, the seat body 1 is arranged on the upper port of the barrel body 10, and the seat body 1 has a garbage delivery port 11, and the seat body 1 is located inside the garbage delivery port 11. An automatic packing mechanism 2 is arranged on the periphery, and the automatic packing mechanism 2 includes a transmission belt mechanism 3 located in the seat body 1 and distributed around the garbage disposal port 11. The transmission belt mechanism 3 has two groups, and the two groups of transmission belt mechanisms 3 are up and down. Layer setting; the automatic packing mechanism 2 also includes a horizontal push rod 4 and a vertical push rod 5, the two ends of the horizontal push rod 4 are respectively connected with the upper and lower drive belt mechanisms 3, and the two ends of the vertical push rod 5 are also connected with the upper and lower layers respectively. The transmission belt me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com