Synthetic resin workpiece demolding device and demolding method thereof

A synthetic resin and demoulding device technology, which is applied in the field of synthetic resin workpiece demoulding devices, can solve problems such as burns to workers and troublesome demoulding of synthetic resin workpieces, and achieve the effect of avoiding burns and improving demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

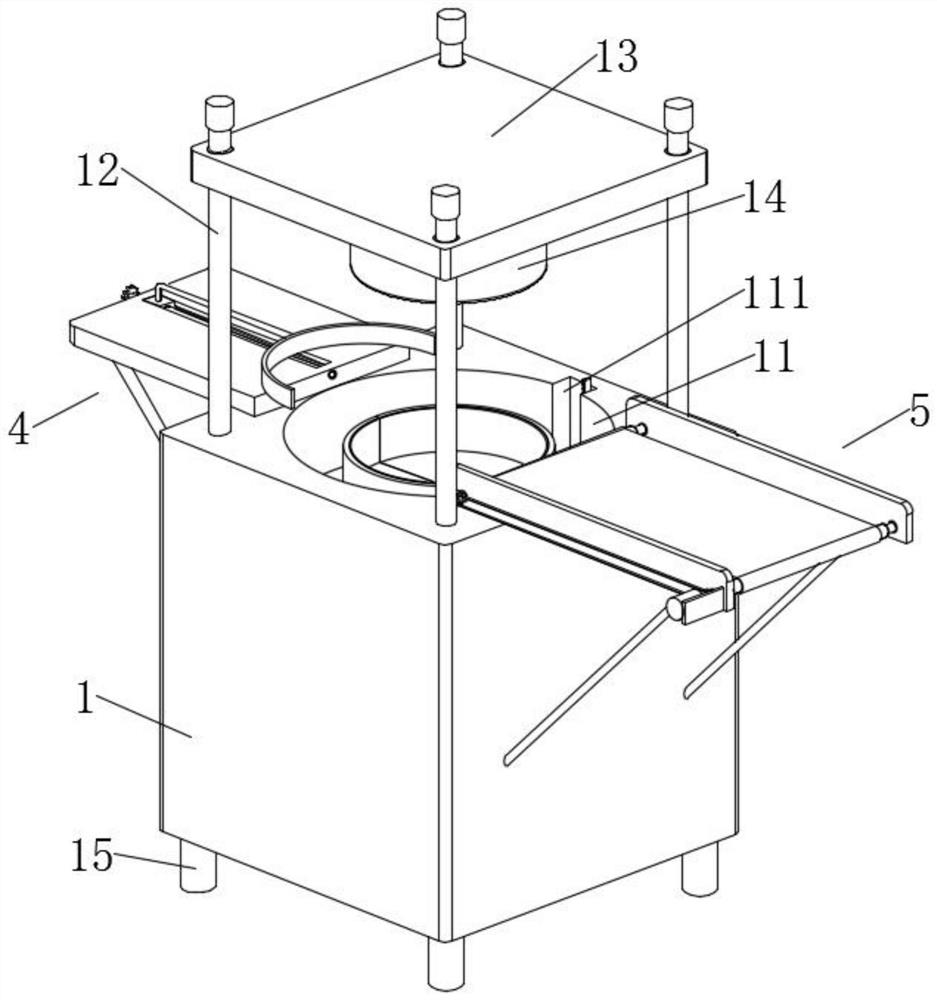

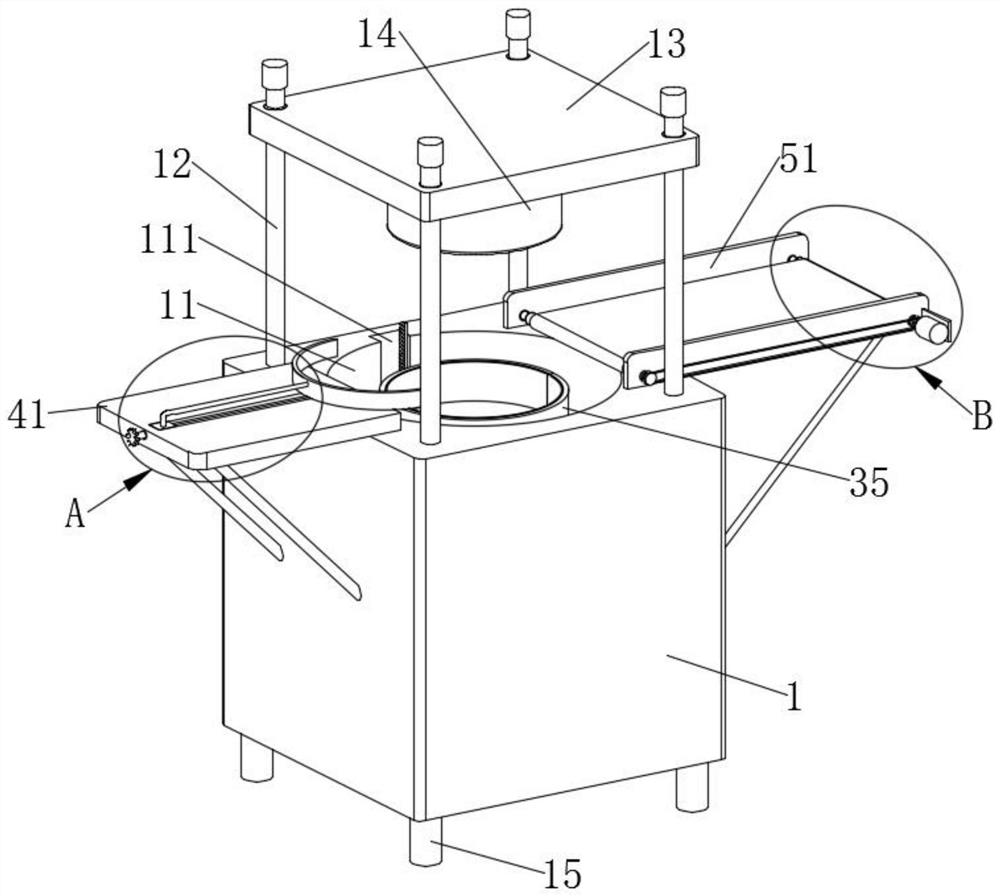

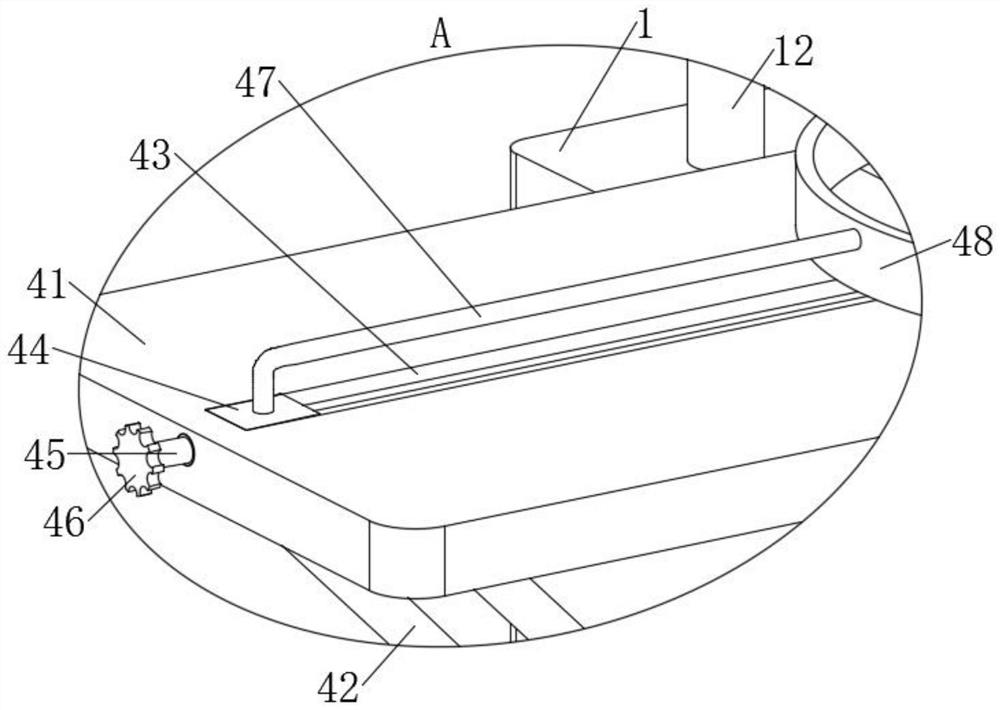

[0033] Example: such as Figure 1-9As shown, the present invention provides a synthetic resin workpiece demoulding device, comprising a mold base 1, the surface of the mold base 1 is provided with a slot 11, the inner wall of the slot 11 is provided with a dark groove 111, the mold base 1 The upper surface is evenly distributed and fixedly installed with guide sliders 12, and the lower pressure plate 13 is slidingly sleeved between the guide sliders 12. The bottom surface of the lower pressure plate 13 is fixed with a die plate 14. By starting the external drive, the lower pressure plate 13 moves along the The surface of the guide slide bar 12 slides vertically downwards, and the lower platen 13 vertically descends the die plate 14, the die plate 14 can mold the synthetic resin, the inside of the slot 11 is provided with a lifting mechanism 2, and the lifting mechanism 2 The surface of the mold is provided with a demoulding mechanism 3, and the lifting mechanism 2 can make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com