Air suspension chassis

An air suspension and chassis technology, applied in conveyors, transportation and packaging, non-mechanical conveyors, etc., can solve the problems of flexible airbag overload, complex manufacturing process, poor structural reliability and durability, and achieve low travel resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

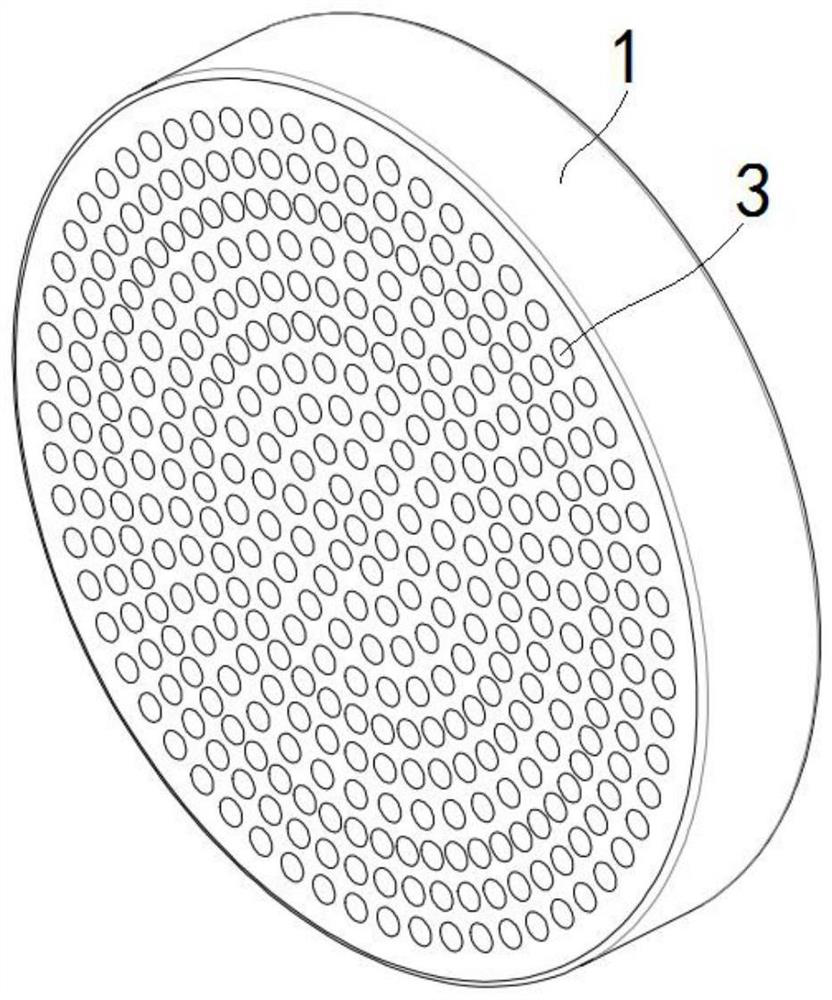

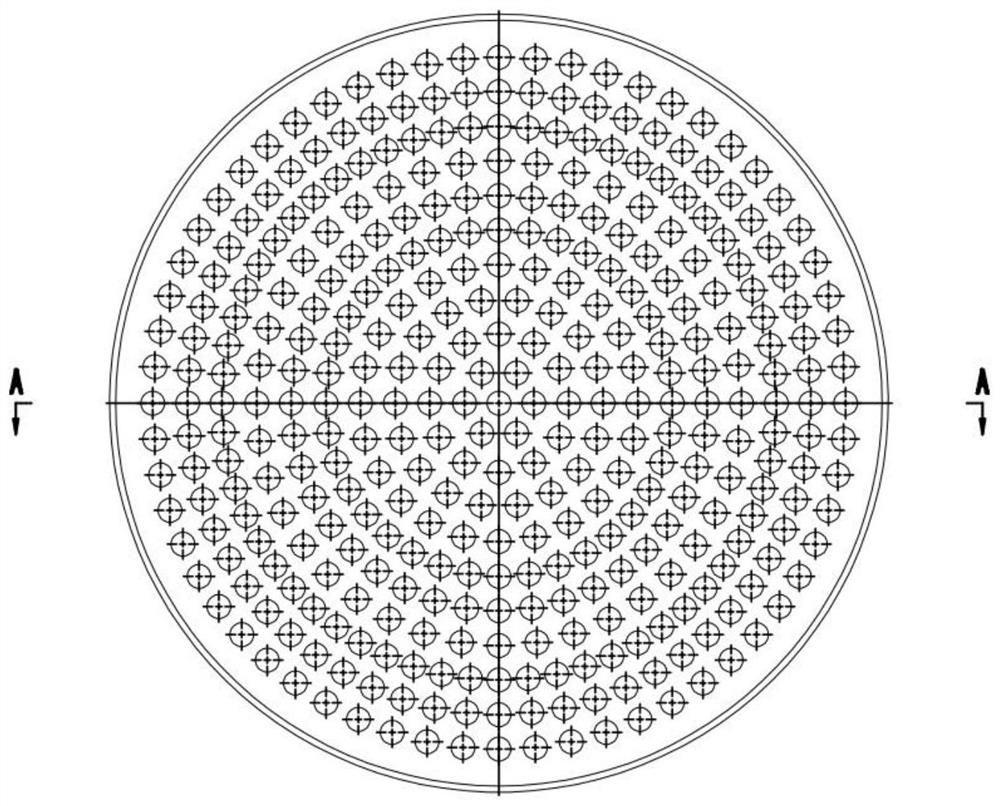

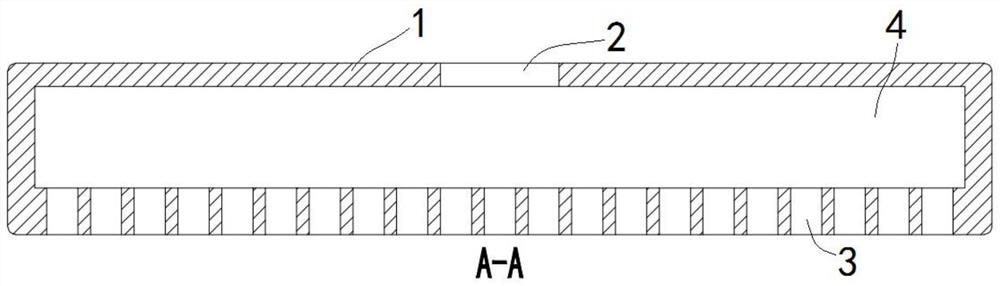

[0033] See attached Figure 1-3 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention, and the present invention specifically discloses an air suspension chassis that slides on a horizontal bearing surface (not shown in the figure) and The air pump (not shown in the figure) is air-connected, including:

[0034] The chassis body 1, the chassis body 1 in this embodiment is in the shape of a disc. Of course, it can also be other shapes, such as rectangle, polygon or a combination of several shapes. One side plate surface of the chassis body 1 is fixed to the load, and the fixing method may be bonding, welding, clamping, bolt connection or other connection methods. An air inlet 2 connected to the air pump is opened in the center of the chassis body 1, and an air outlet connected to the air inlet 2 is provided on the side plate of the chassis body 1 away from the load, and an air outlet of the air outlet is opened on the chassis ...

Embodiment 2

[0038] See attached Figure 4-6 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that: on the side plate surface of the chassis body 1 where the air outlet is provided, it is radially uniform with its axis as the center. The cloth is provided with a plurality of through grooves-14, and the plurality of through grooves-14 are all communicated with the air inlet 2, and the air outlet in the present embodiment includes a plurality of annular air outlet grooves-5, and the plurality of air outlet grooves-5 are all connected to the chassis. The body 1 is coaxially arranged, and a plurality of outlet slots 15 communicate with the inlet holes 2 through a plurality of through slots 14 .

Embodiment 3

[0040] See attached Figure 7-9 It is a schematic diagram of the overall and partial structure of an embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that the air outlet in this embodiment includes an air outlet 2 6 and an annular air outlet groove 2 7, and the air outlet 2 6 There are multiple air outlet slots 2 and 7 respectively, and the multiple air outlet slots 7 are coaxially arranged with the chassis body 1. The multiple air outlet holes 6 are all limited to the inside of the air outlet slot 7 with the smallest diameter and arranged uniformly. The inside of the body 1 is integrally formed with an air cavity 28 with a circular cross section. The bottom wall of each air outlet groove 27 is provided with a plurality of through holes 15 communicating with the air cavity 28. The plurality of air outlet holes 26 are all connected to each other. It communicates with the second air cavity 8, and the air inlet 2 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com