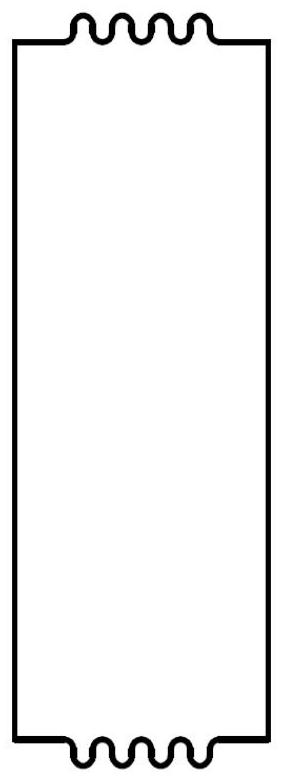

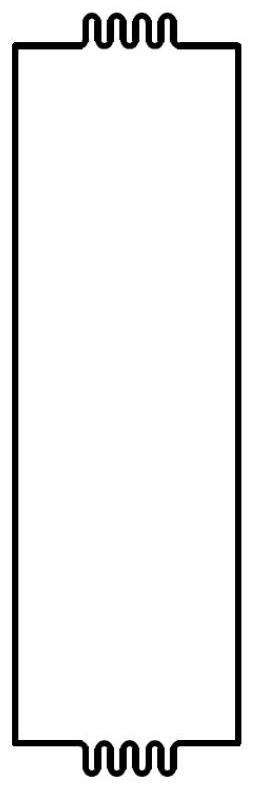

Automatic shaping machine for metal corrugated pipe

A metal bellows and shaping machine technology, which is applied in the field of metal bellows automatic shaping machines and bellows shaping equipment, can solve problems such as difficult to meet bellows, impact or jamming, and insufficient overall rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

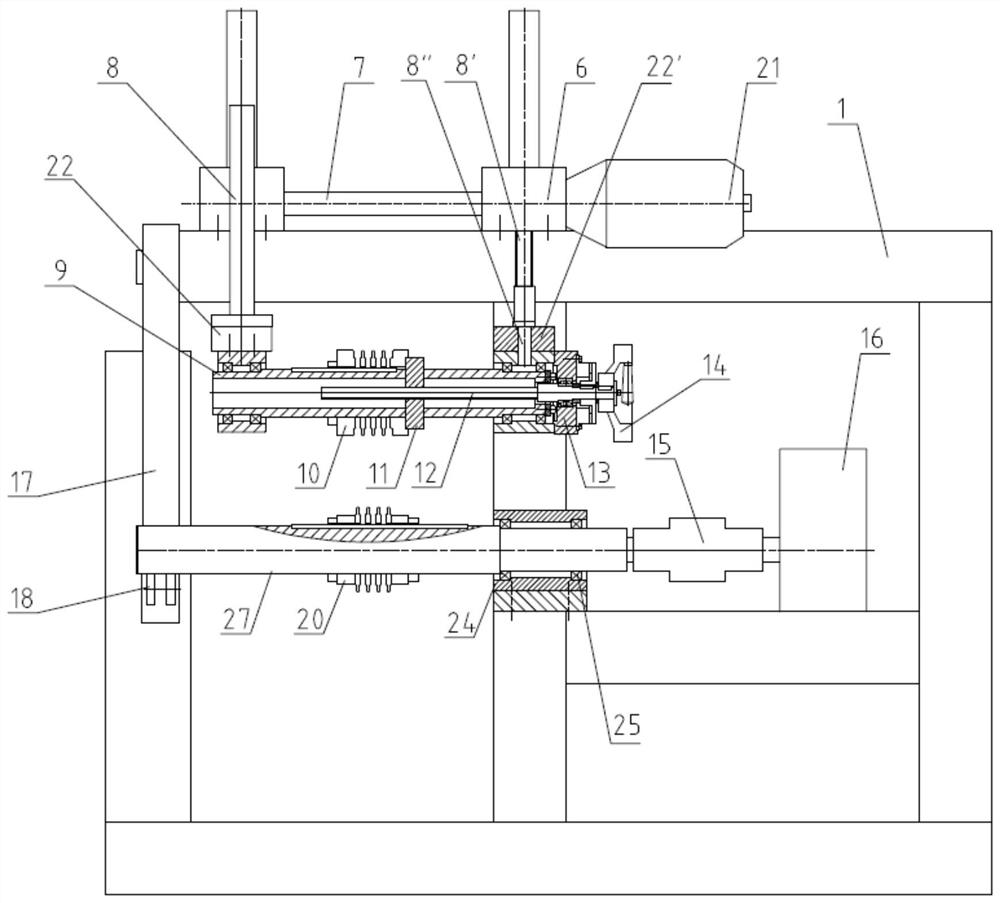

[0030] The technical solutions in this embodiment will be further described in detail below in conjunction with the accompanying drawings.

[0031] This embodiment is a metal bellows multi-wave automatic shaping machine as bellows shaping equipment, and its specific structure is as follows image 3 and Figure 4 As shown, the main motor 16 containing the speed reducer is arranged at the bottom of the frame 1 of the frame structure, the output shaft of the main motor is connected to the horizontal driving shaft 27 through a coupling 15, and the driving shaft 27 is equipped with clamping blocks at both ends and The active shaping die 20 is composed of distributing die sheets at intervals in the middle, and under the constraint of the feather key structure, the active rotating shaft 27 and the active shaping die 20 constitute a circumferentially moving pair constrained by the circumferential direction. The upper part of the frame 1 is equipped with a hoist 6 driven by a hoist mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com