Radix ophiopogonis harvesting method

A harvesting method and technology of Ophiopogon japonicus, applied in the field of Ophiopogon japonicus harvesting, can solve the problems of difficulty in screening, high labor intensity, low efficiency, etc., and achieve the effects of improving soil entry effect, improving soil crushing ability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for harvesting Ophiopogon japonicus is realized based on an Ophiopogon japonicus harvester, and the specific process is as follows:

[0073] (1) Connect the Ophiopogon japonicus harvester to the rear of the tractor, and use the tractor as the power to pull the Ophiopogon japonicus harvester forward;

[0074] (2) During the forward process of the Ophiopogon japonicus harvester, the materials mixed with Ophiopogon japonicus and soil are dug out through the second-order curved surface excavation shovel:

[0075] The sawtooth at the front end of the shovel penetrates into the soil layer at a depth of 20-30cm to break the soil layer;

[0076] The shovel surface enters under the broken soil and gradually raises the bottom of the soil;

[0077] During the lifting process, the soil is split from the middle by the triangular pyramid in the middle of the shovel surface, so that the materials are respectively located on the shovel surfaces on both sides of the triangular...

Embodiment 2

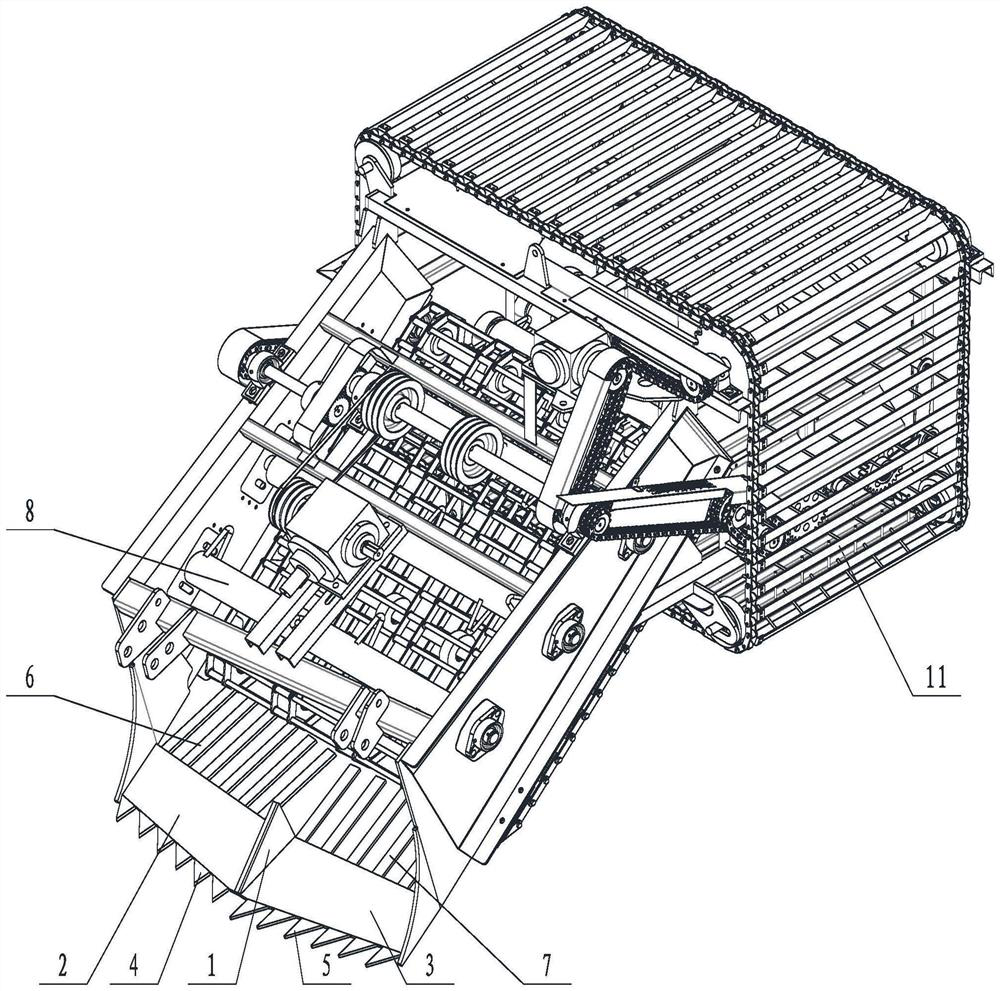

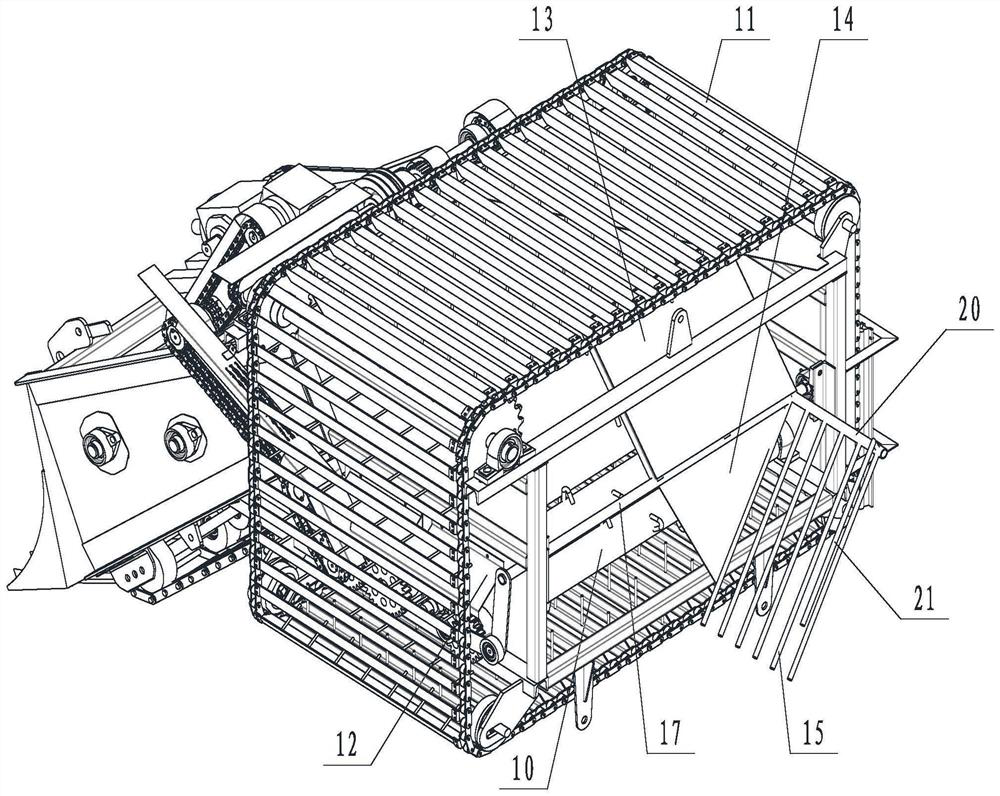

[0100] Such as Figure 1 to Figure 3 The shown Ophiopogon japonicus harvester is used to realize the Ophiopogon japonicus harvesting method as described in embodiment 1, comprising:

[0101] Excavation system, used to dig out the soil to be harvested Ophiopogon japonicus;

[0102] The conveying system is used to convey the materials excavated by the excavating system to the first-stage roller crushing device;

[0103] The crushing and crushing system is used to crush and crush the materials during the conveying process of the conveying system;

[0104] The first-stage roller crushing device is used for the first-stage roller crushing of the soil attached to the rhizome of Ophiopogon japonicus;

[0105] The second-stage roller crushing device is used for the second-stage roller crushing of the soil attached to the rhizome of Ophiopogon japonicus;

[0106] The circular screening system is used to transport the material passing through the first-stage roller crushing device to...

Embodiment 3

[0141] Based on the Ophiopogon japonicus harvester of embodiment 2, the difference between this embodiment and embodiment 2 lies in the structure of the rack.

[0142] The rack of the present embodiment is as Figure 12 As shown, it includes several rod groups connected to the second connecting rod 20, and each rod group is composed of two symmetrically distributed special-shaped rods 26, wherein the special-shaped rods 26 are evenly distributed with several arc-shaped segments along the long axis direction 261. In any rod group, the concave surface of the arc section 261 between two special-shaped rods 26 is opposite, and a first widened portion 262 is formed between two opposite arc sections 261; , the arc segments 261 on both sides automatically form a portion with reduced width, so the relative position of the non-arc segments between two adjacent rod groups is defined as the second widening 263 .

[0143] The design of this embodiment is because in a large number of exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com