Adhesive tape machine system experiment platform

An experimental platform and tape machine technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of large space occupation and high price, and achieve the effect of small footprint and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

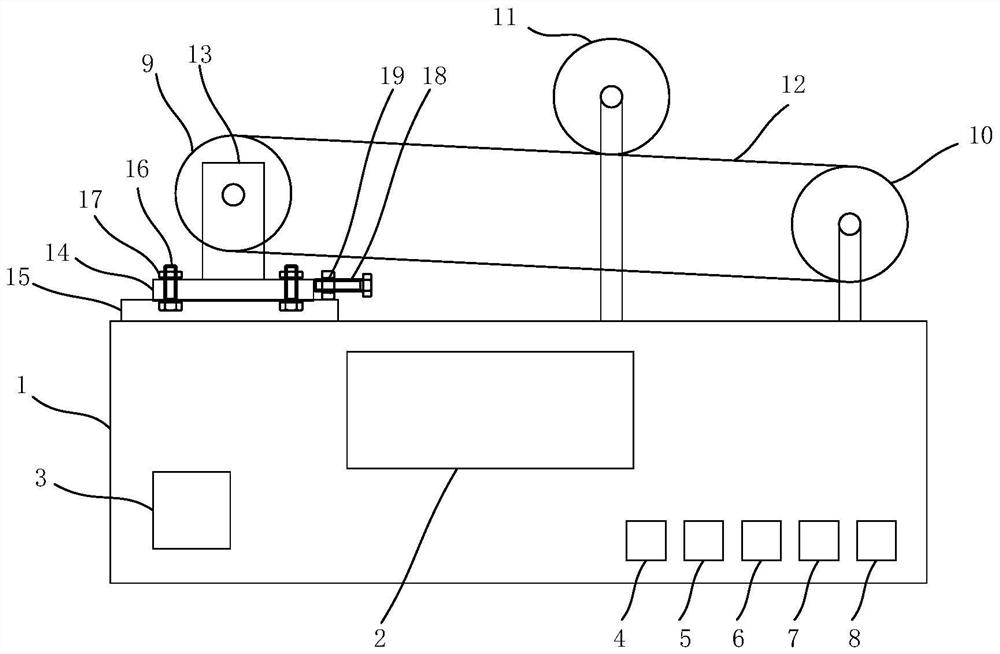

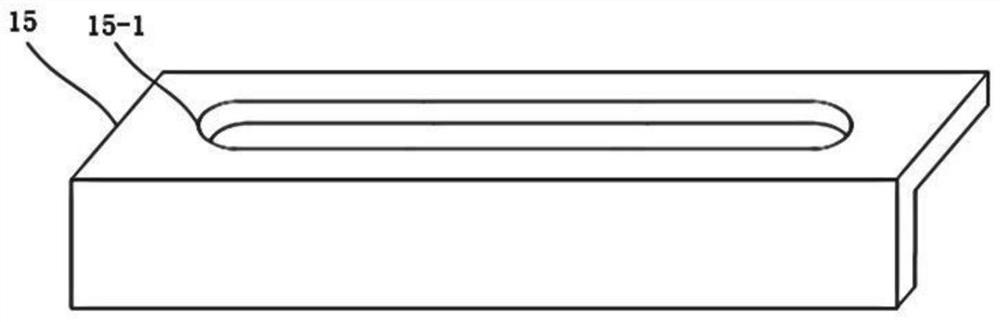

[0028] like figure 1 As shown, the experimental platform of the belt conveyor system includes the control box 1 and the belt conveyor, and the control box 1 includes the main controller of the KTC-101Z belt conveyor, the power box, the heating device 3, and the test interface. The belt conveyor is installed on the top of the control box 1.

[0029] The main controller of KTC-101Z belt conveyor has an overall size of 600mm×310mm×340mm, including the main control module, along-line detection module, I / O module, and language alarm module. The main controller of KTC-101Z tape machine also has a liquid crystal display screen 2 and multiple keys for starting and stopping. The main controller of KTC-101Z tape machine has four working modes: centraliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com