High-precision detection device for foamed aluminum European layer composite board

A detection device, the technology of aluminum European layer, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of affecting plate processing, large debris, reducing work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

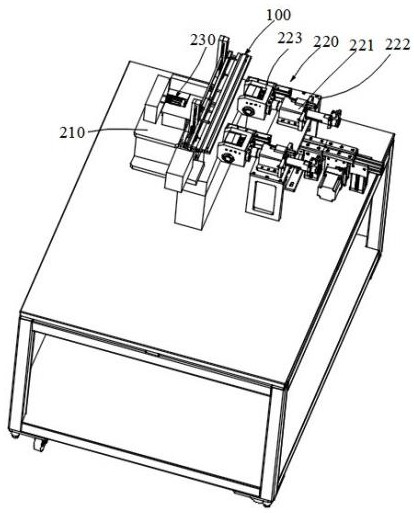

[0052] Such as Figure 1~8 As shown, a high-precision detection device for aluminum foam European-layer composite panels, including,

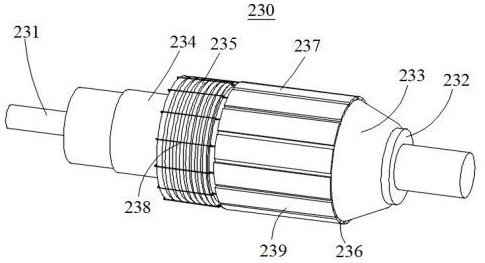

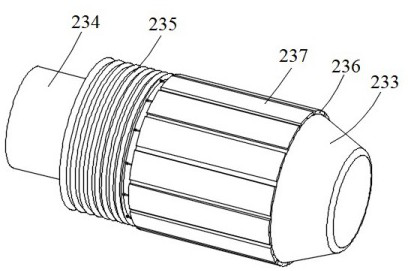

[0053] Cutting system and the drilling system 200 arranged under the cutting system, the drilling system 200 includes a bracket 210, a mounting part 220 arranged on one side of the bracket 210 and a drilling hole opposite to the mounting part 220 part 230, the drilling part 230 includes a main shaft 231 fixedly arranged on the support 210, a milling cutter 232 rotatably arranged on the main shaft 231, and a protective sleeve sleeved on the milling cutter 232. The protective cover includes a protective frame 234, an air bag 235 connected with the protective frame 234, a protective cover 233 connected with the air bag 235 and an air blowing ring 237 arranged on the protective cover 233, and,

[0054] The air bag 235 communicates with the air hole 236 on the blowing ring 237, wherein,

[0055] When the installation part 220 transports the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com