Engineering optimization method for horizontally blocking and resisting organic gas erosion

An organic gas, engineering optimization technology, applied in the direction of infrastructure engineering, filling, protection devices, etc., can solve the problem of water loss and drying of geosynthetic clay liner, water loss and cracking of compacted clay layer, and water loss and cracking of clay liner, etc. problems, to achieve the effect of simple access, preventing water loss and cracking, and enhancing anti-seepage and gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

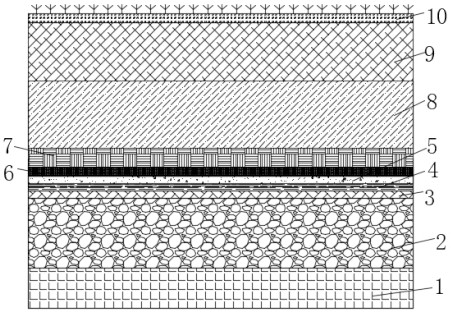

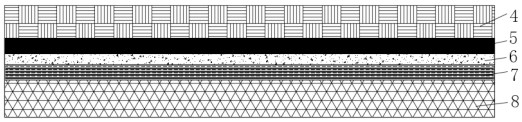

[0036] The present invention proposes an engineering optimization method for horizontal barrier resistance to organic gas erosion. In the engineering optimization method, the horizontal barrier system (such as figure 1 ) from bottom to top, there are polluted soil layer 10, compacted clay layer 9, geosynthetic clay liner 8, first geomembrane 7, modified asphalt layer 6, second geomembrane 5, temperature control layer 4, protective layer 3, topsoil 2 and vegetation 1, and the structural effect of geomembrane-modified asphalt layer-geomembrane is as follows figure 2 .

[0037] in:

[0038] The content of the attapulgite in the compacted clay layer 9 is 5%. The raw ore of the attapulgite is produced in Xuyi, Jiangsu Province. After crushing, preliminary screening, beating, filtering, and drying, the attapulgite is passed through a 100-mesh sieve for use;

[0039] The compacted clay is local clay, which should be dried for more than 12 hours before use. After the clay and attap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com