Manhole cover automatic locking device and intelligent powder and particle material transportation tank car

An automatic locking and manhole cover technology, applied in the direction of goods transport vehicles, oil tankers, motor vehicles, etc., can solve the problems of increasing labor costs, cumbersome operations, wasting time, etc., and achieves simple structure, improved safety, and guaranteed The effect of personnel safety and property safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

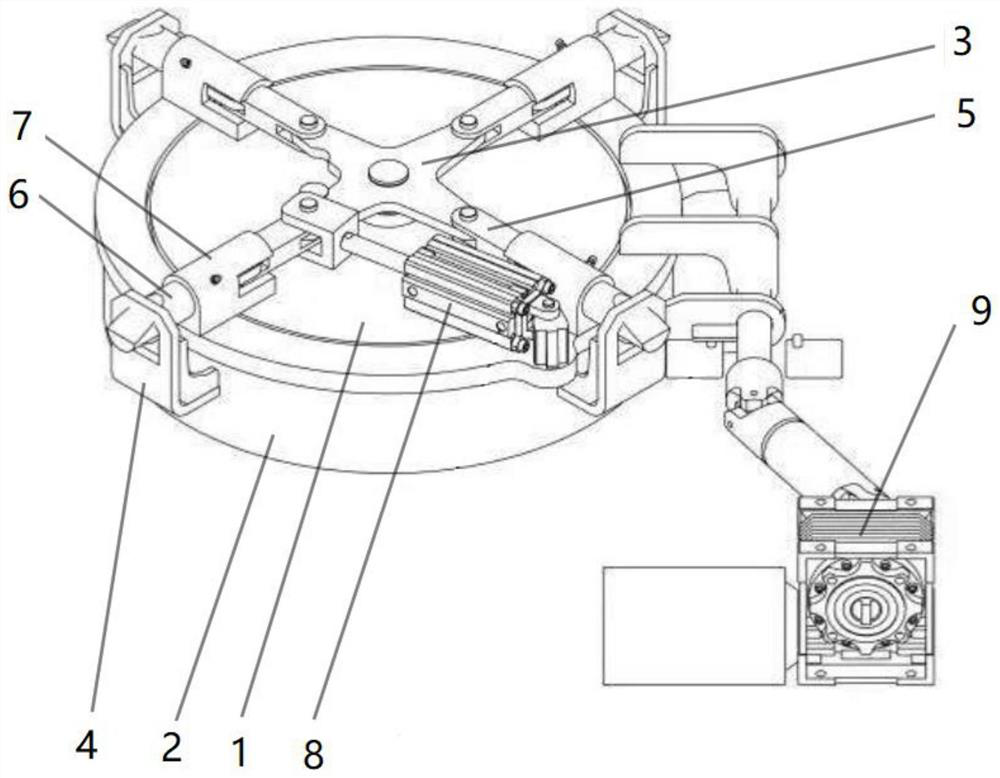

[0027] Such as figure 1 As shown, this embodiment provides an automatic locking device for the manhole cover 1, which includes a rotating part 3 arranged on the manhole cover 1, a rotating drive part for driving the rotating part 3 to rotate, and several clamping parts. A number of clamping seats 4 are fixed on the hole collar 2, and a clamping interface is arranged on the clamping seat 4. The clamping part includes a hinged first connecting rod 5 and a pin shaft 6, and the end of the first connecting rod 5 is hinged on the On the rotating part 3, the pin shaft 6 is passed through the guide seat 7, the guide seat 7 is fixed on the manhole cover 1, and includes a guide groove for guiding the pin shaft 6, the end opening of the guide groove is connected with the card interface Facingly, when the rotating part 3 rotates in the forward direction, the end of the pin shaft 6 is stretched into the card interface and clamped.

[0028] When in use, when the manhole cover 1 is closed a...

Embodiment 2

[0037] This embodiment provides an intelligent tank truck for transporting powder and granular materials, which includes a tank body, and the top of the tank body is provided with the above-mentioned automatic locking device for the manhole cover 1 .

[0038] Further, in this embodiment, the tank body is also provided with an automatic unloading system. The automatic unloading system includes a discharge controller, a pressure transmitter for detecting the pressure in the tank, and a pressure transmitter for detecting the speed of the on-board air compressor on the tank truck. The rotational speed sensor and the unloading valve group, the pressure transmitter, the rotational speed sensor and the unloading valve group are all electrically connected with the unloading controller.

[0039] Specifically, the unloading valve group includes a front air chamber intake valve, a rear air chamber intake valve, a secondary blowing assist valve, an unloading valve, a pressure relief valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com