Function-optimized fast switching system

A function and unit power technology, applied in the field of function-optimized fast switching system, can solve the problems of transformer overload, unable to adjust the load of parallel units, power failure of the whole plant, etc., to improve reliability, realize non-disturbance correction, and simple wiring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

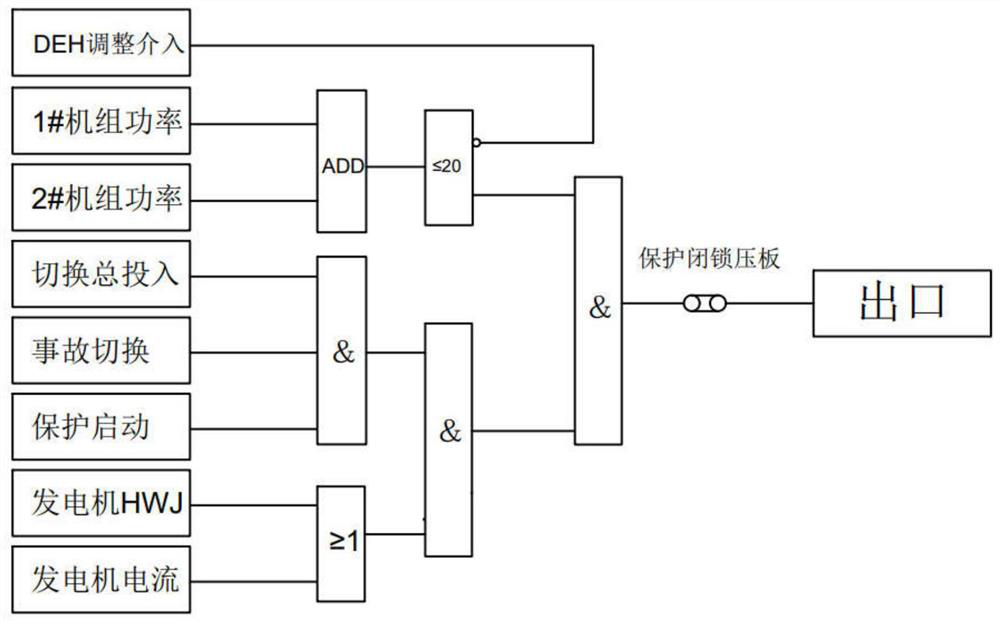

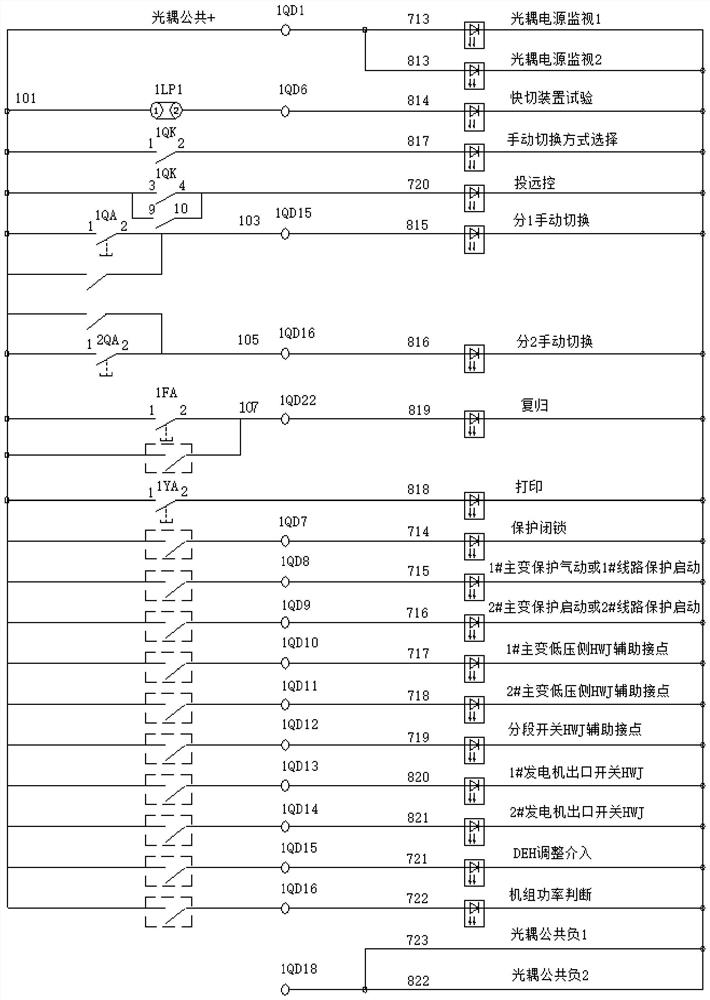

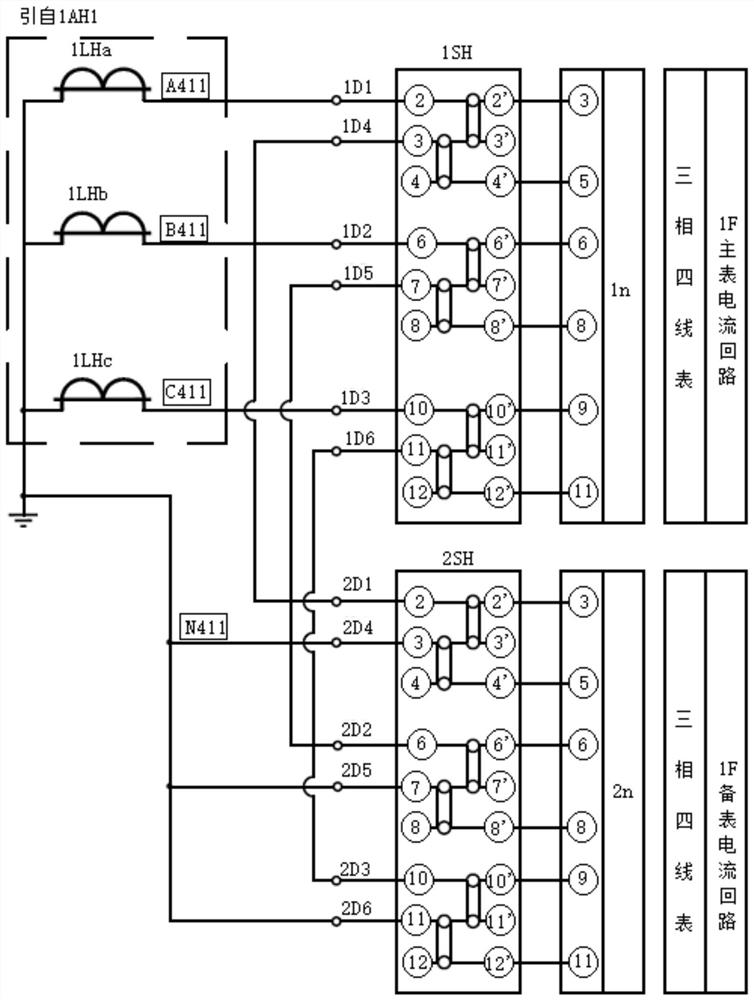

[0033] Such as Figure 1-4 As shown, a function-optimized quick-cutting system includes a quick-cutting device. The quick-cutting device adjusts the intervention by adding DEH in the open-in circuit, judges the power of the unit, and tests the pressure plate circuit of the quick-cutting device. The electrical signal circuit is connected to The power signal of the two units, the connection of each circuit adopts shielded soft wire;

[0034] The DEH adjustment intervention uses a normally open contact as a limiting condition for safe switching when the units are running in parallel in the accident switching, and the DEH adjustment intervention is to lead the power control unit in the steam turbine governor to the fast switching device;

[0035] The unit power j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com