High-speed train suspension system fault diagnosis method based on data-driven ToMFIR

A suspension system, high-speed train technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems of sensor deviation drift, performance degradation, loss of small-scale actuation efficiency of actuators, etc. achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below in conjunction with the accompanying drawings.

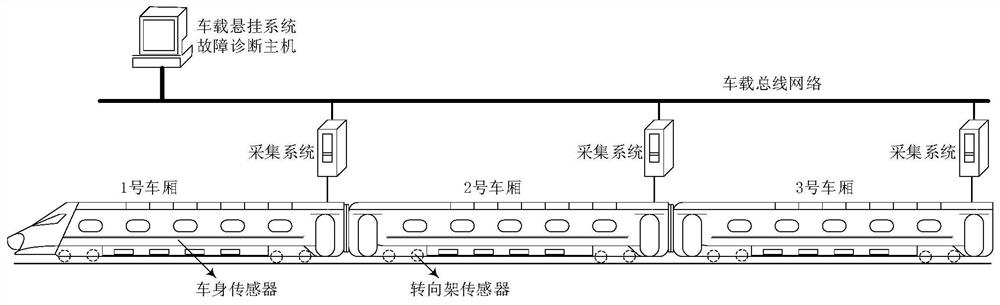

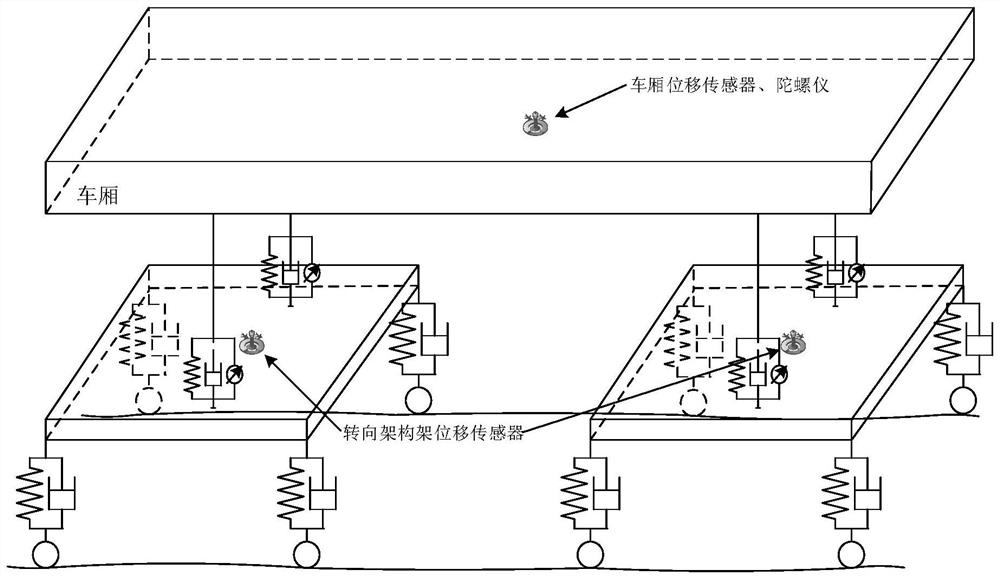

[0100] figure 1 It is a structural schematic diagram of a high-speed train suspension system fault diagnosis system according to an embodiment of the present invention. like figure 1 As shown, the fault diagnosis system includes: a sensor for obtaining the vertical displacement and pitch angle of the center of gravity of the train and the vertical displacement of the center of gravity of the bogie frame; an acquisition system for collecting and processing the measurement data of the sensor and sending it to the fault diagnosis host ; Fault diagnosis host computer judges whether the suspension system of the high-speed train is faulty and estimates the magnitude of the fault through the collected information. The installation positions of sensors and gyroscopes in each car are as follows: figure 2 shown.

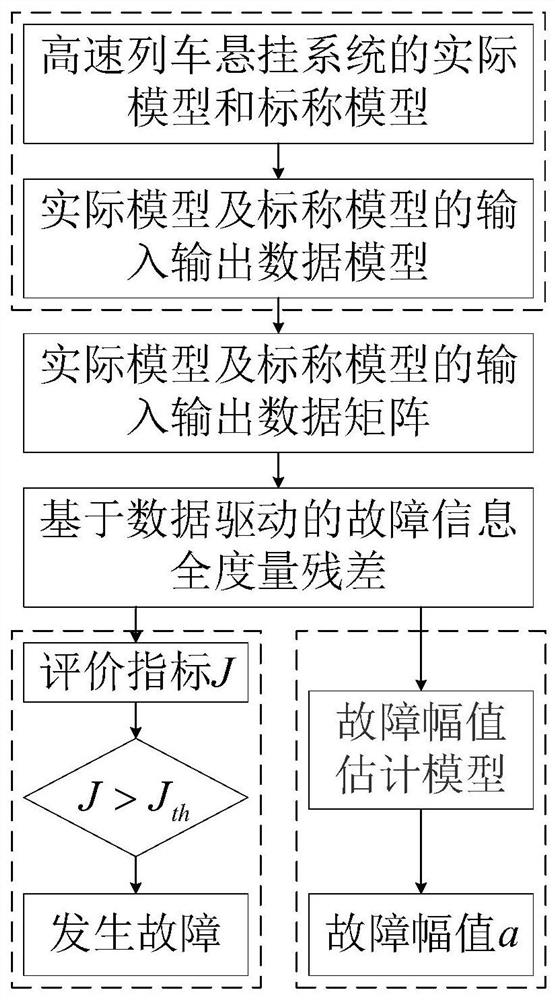

[0101] like image 3 As shown, the micro-fault di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com