Electronic lock body

A technology for electronic locks and lock bodies, which can be used in building locks, non-mechanical transmission-operated locks, door/window accessories, etc. It can solve the problems that require a lot of force, and achieve the effect of saving effort in unlocking or locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

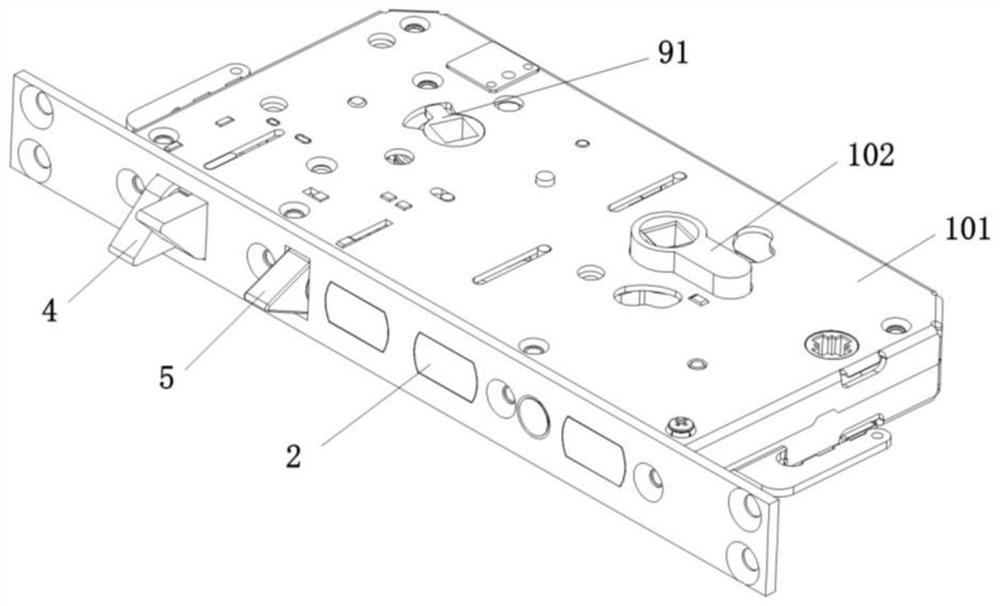

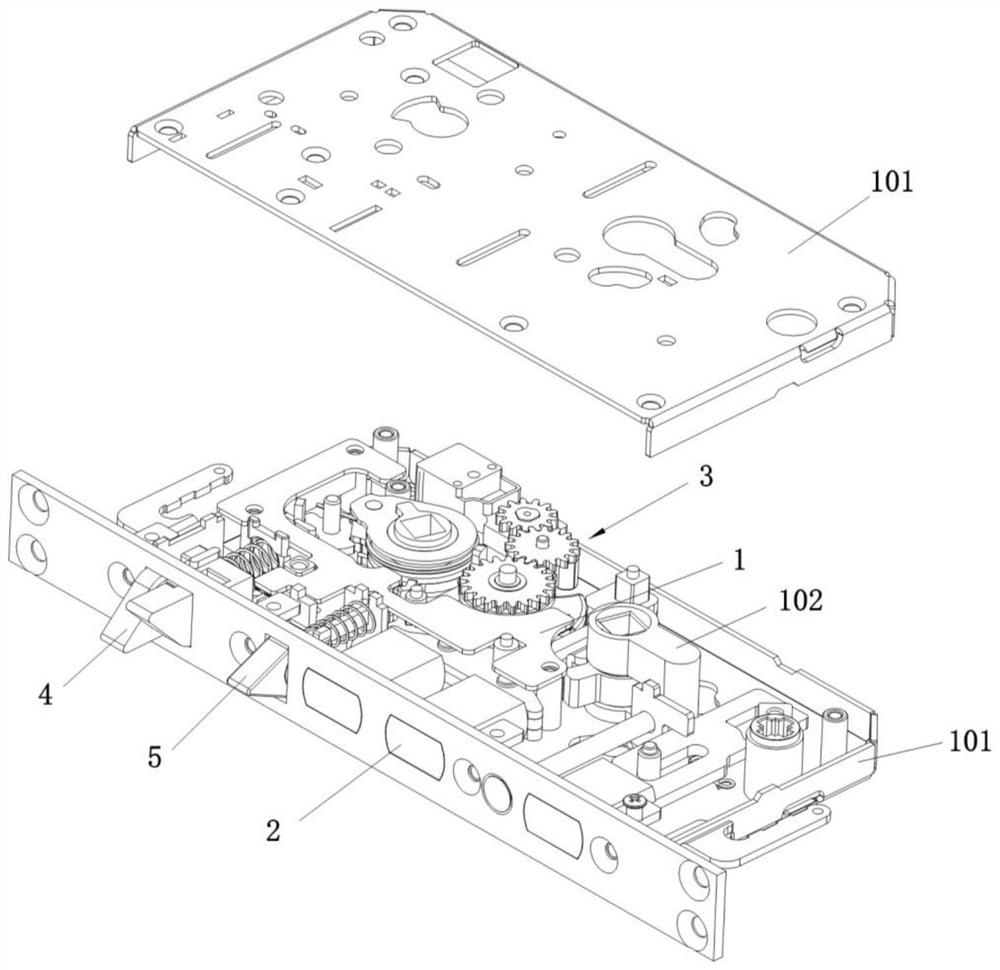

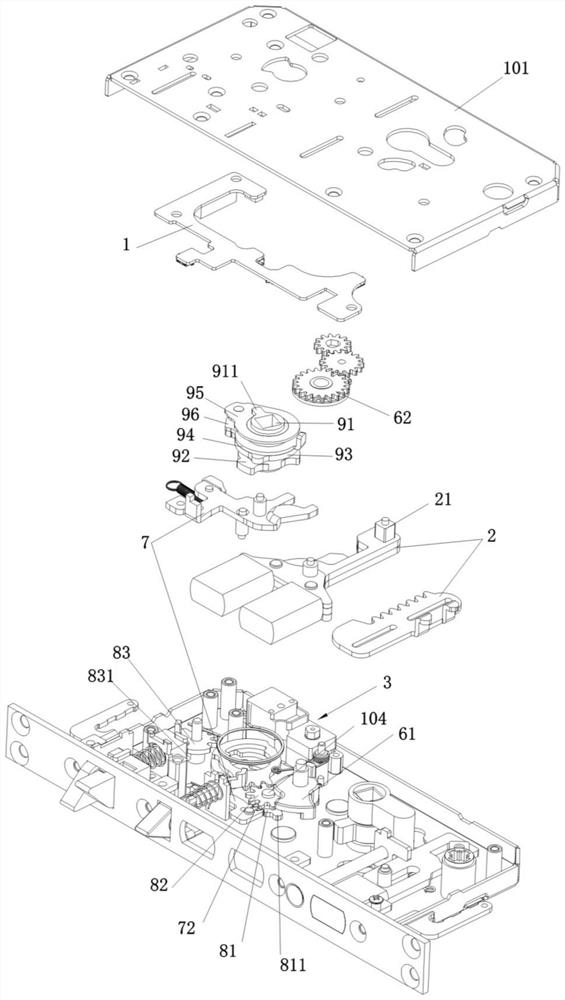

[0037] as attached figure 1 to attach Figure 4 As shown, an electronic lock body includes a lock case 101, a PCB board 1, a lock body control module, a square tongue assembly 2, a square tongue transmission device, a motor assembly 3, a lock cylinder 102, an oblique bolt assembly 4 and a triangular tongue assembly 5 The square tongue transmission acts on the square tongue assembly 2 to make the square tongue protrude or retract into the lock body (or lock housing 101) to realize the locking and unlocking functions of the lock body, and the lock core 102 is connected with the square tongue assembly 2.

[0038] as attached Figure 5 to attach Figure 8 As shown, the square tongue transmission device includes a pulling rod 61 and a motor gear 62 that are rotatably installed on the same first pivot shaft 103, and the motor gear 62 has an arc extending with the first pivot shaft 103 as the central axis. Arc groove 621; as attached Figure 9 And attached Figure 10 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com