Cast-in-place bridge formwork support system device and bridge cast-in-place rapid construction method

A technology of cast-in-place bridges and formwork, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low construction efficiency, time-consuming and manpower, and achieve the effect of improving construction efficiency and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

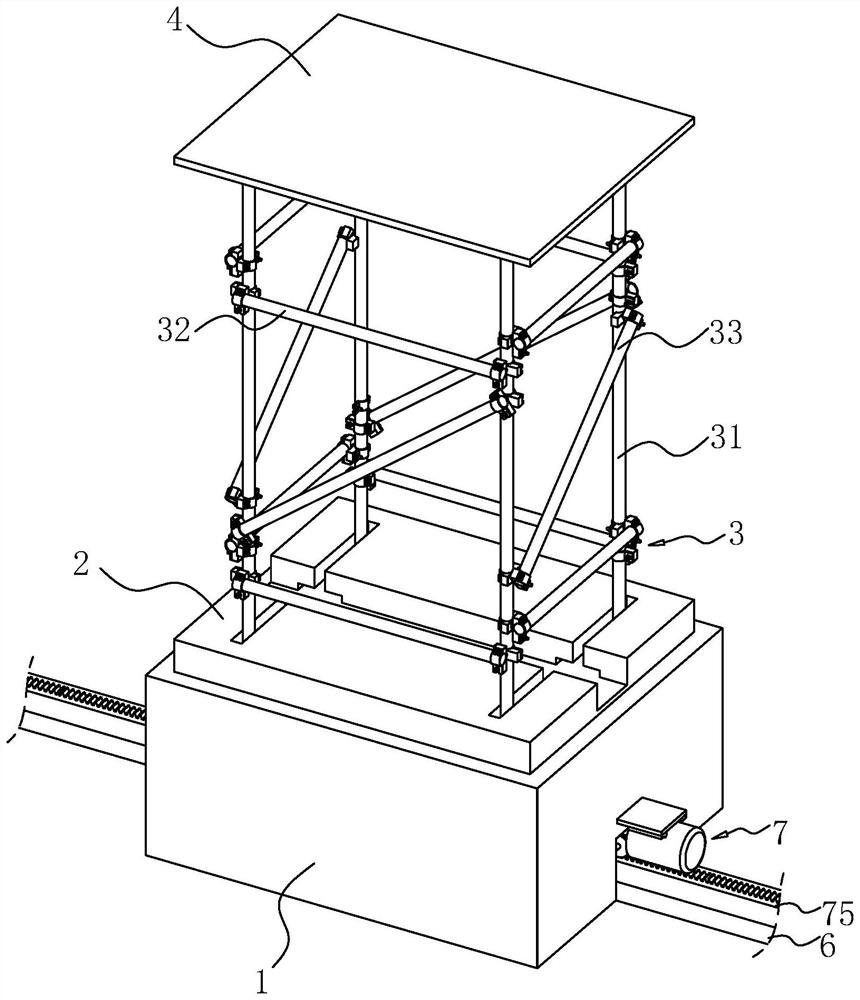

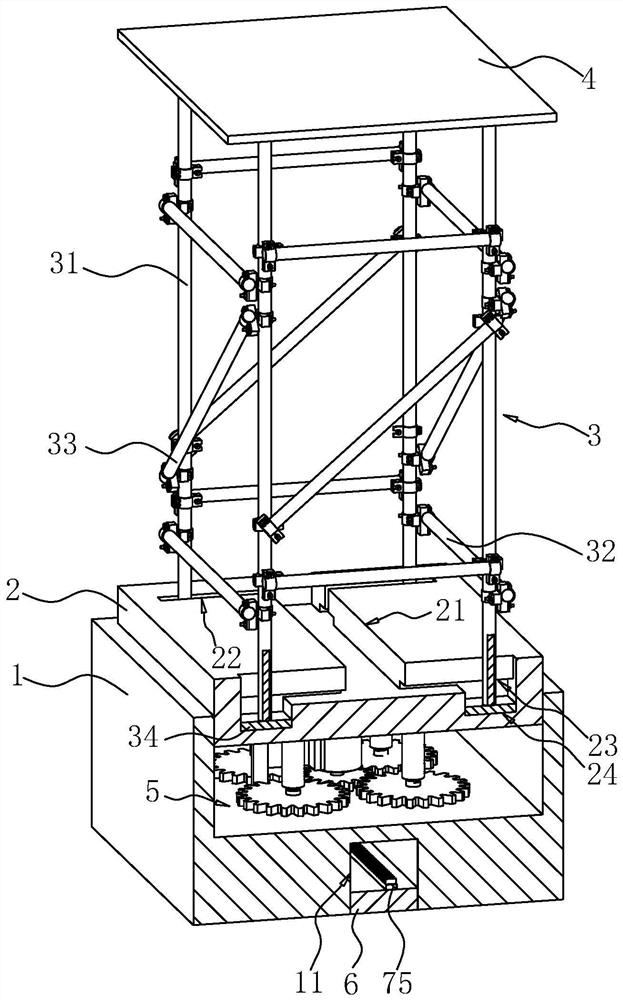

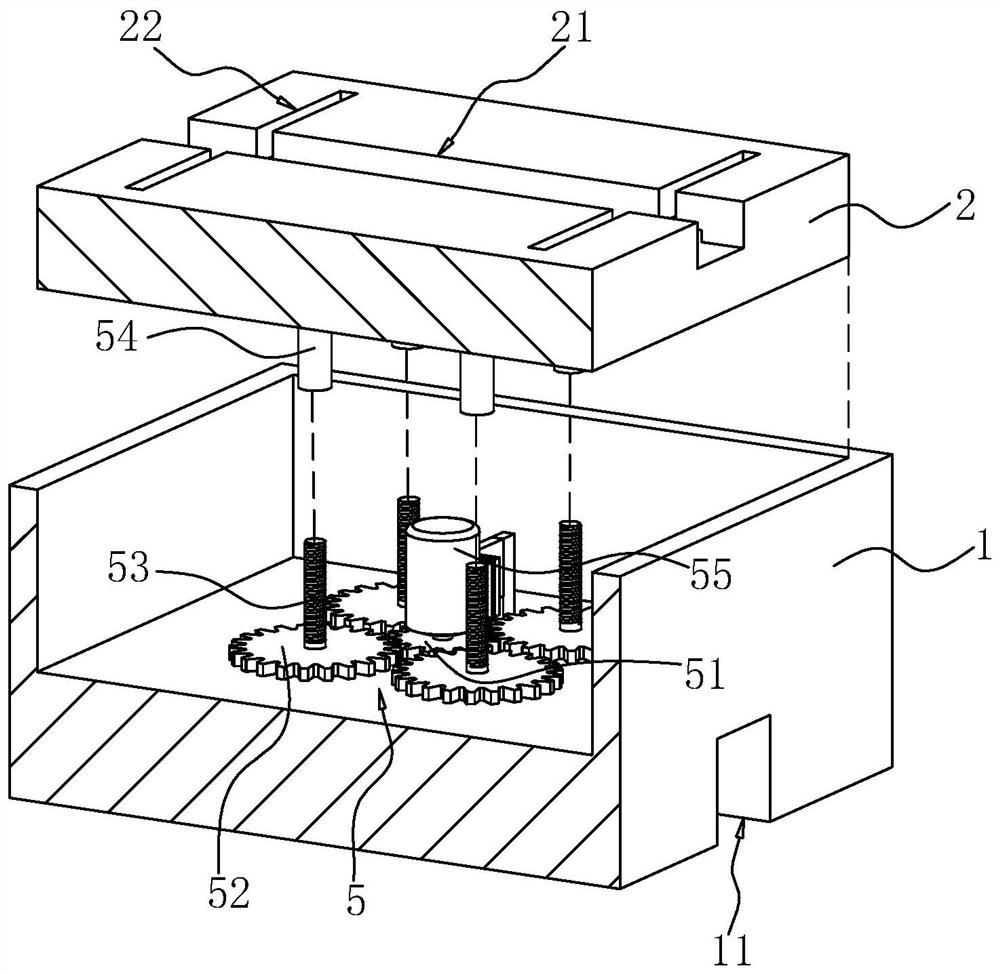

[0042] The following is attached Figure 1-5 The application is described in further detail.

[0043] The embodiment of the present application discloses a cast-in-place bridge formwork support system device. refer to figure 1 and figure 2 , the template support system device includes several sliding boxes 1, a cavity is opened on the top surface of the sliding box 1, and a socket 2 is slidably inserted in the sliding box 1, and the formwork support system also includes several templates Bracket 3, a template bracket 3 is installed on each socket 2, and a template 4 is installed on the top of the template bracket 3; the inner bottom wall of the sliding box 1 is provided with a control socket 2 to raise or lower Complement component 5. Before the bridge construction, the operator lays a number of rails 6 according to the predetermined construction plan, and the rails 6 provide guidance for the movement of the sliding box 1 . The bottom surface of the sliding box 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com