Intelligent cleaning equipment for transformer substation electrical equipment insulator

A technology for electrical equipment and cleaning equipment, applied in cleaning methods and appliances, chemical instruments and methods, motor vehicles, etc., can solve the problem of inability to effectively ensure the coverage of cleaning operations, difficulty in adapting to the operating environment of substations, and unintegrated and diversified detection functions to avoid device positioning failure, improve the level of automation and intelligence, and avoid personnel contact problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

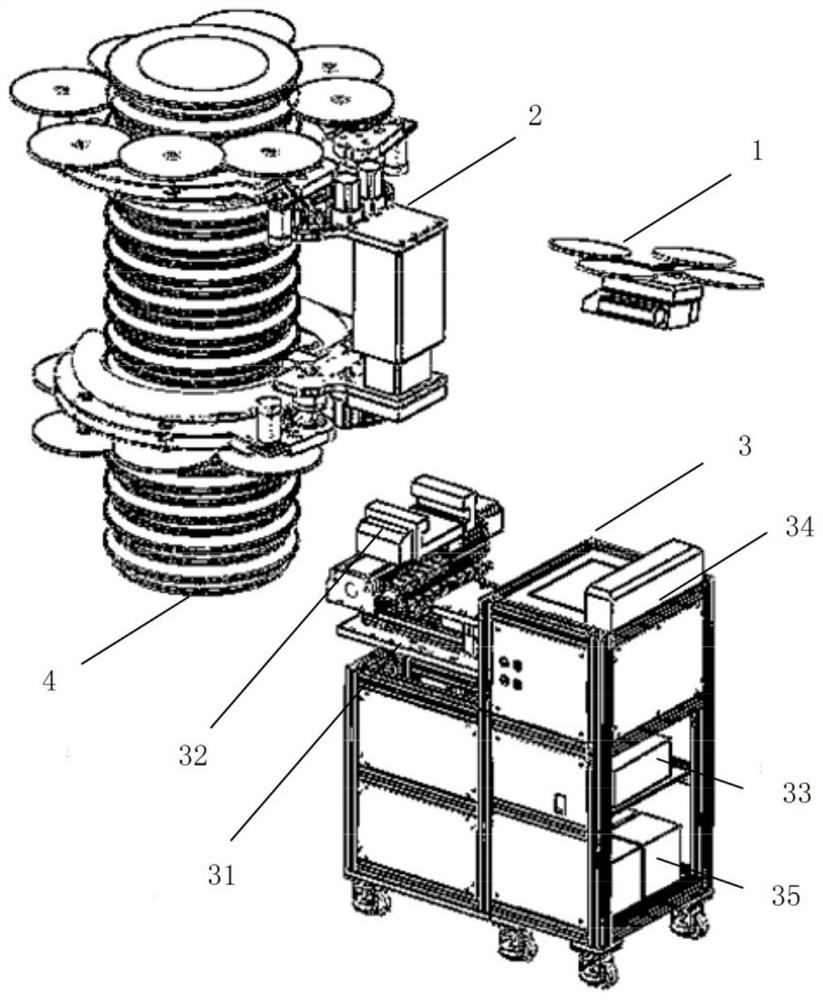

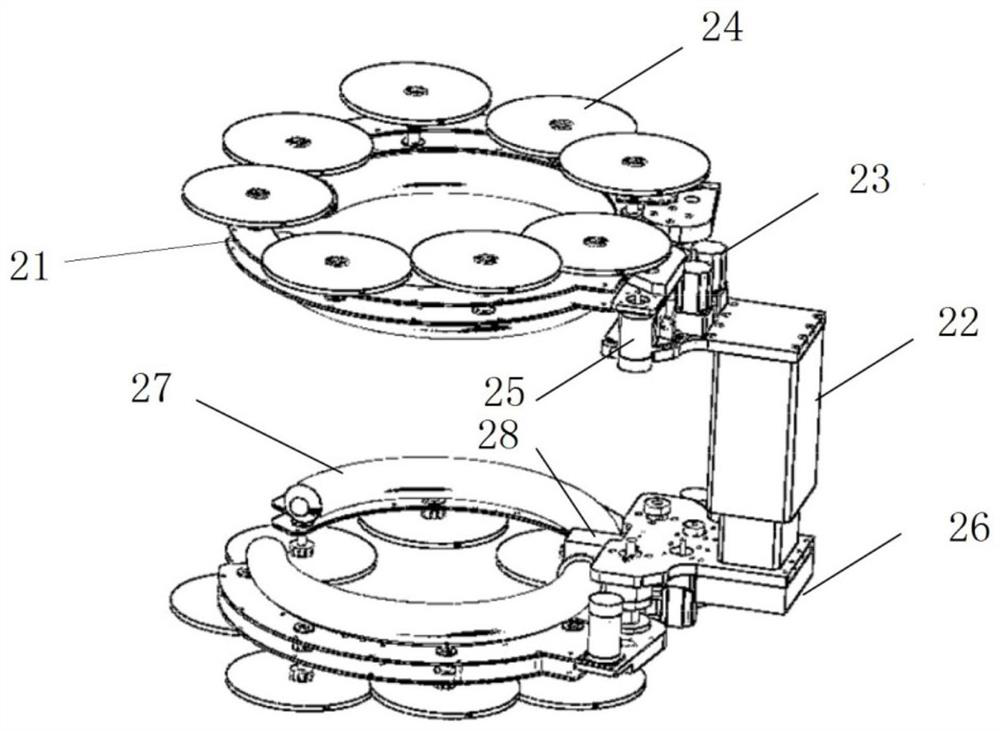

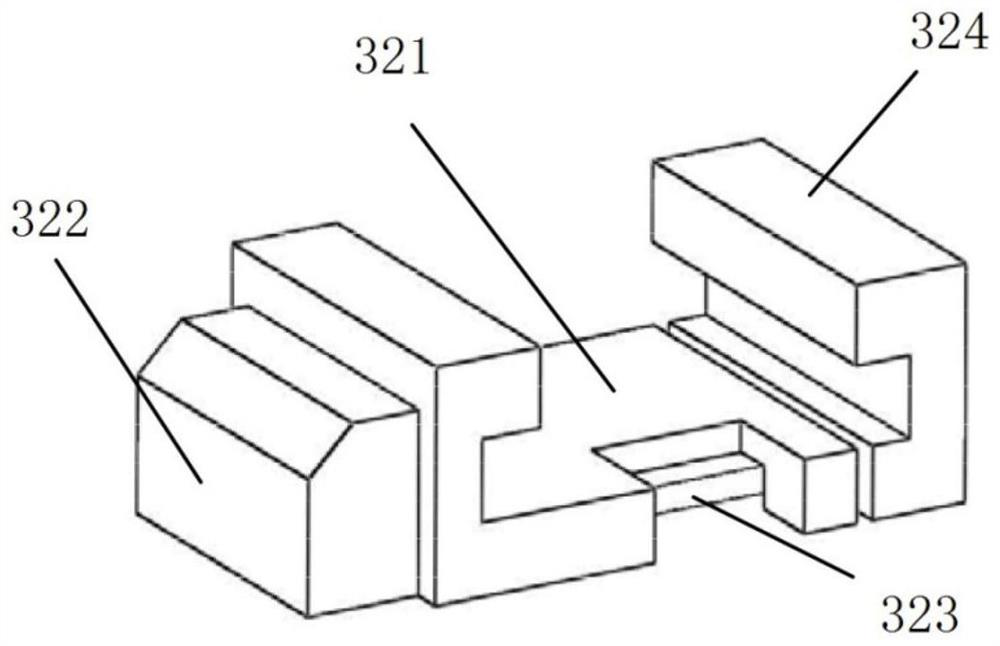

[0050] Such as figure 1 As shown, the present invention provides intelligent cleaning equipment for substation electrical equipment insulators, including a monitoring feedback unit 1 (Monitoring Feedback Unit, MFU), a climbing cleaning unit 2 (Climbing ClearUnit, CCU) and a main body carrying platform 3 (Main Carrier, MC).

[0051] (1) Monitoring Feedback Unit 1 (Monitoring FeedbackUnit, MFU)

[0052] The monitoring and feedback unit 1 of the substation insulator intelligent cleaning equipment consists of a UAV with flexible flight and movement capabilities and a high-definition camera mounted on it, an infrared sensor, an ultraviolet sensor, an ultrasonic sensor, and an electric field strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com