Rotary cutting machine

A cutting machine, rotary technology, applied in metal processing and other directions, can solve the problems of inability to cut, incomplete cutting, trouble, etc., to achieve the effect of increasing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

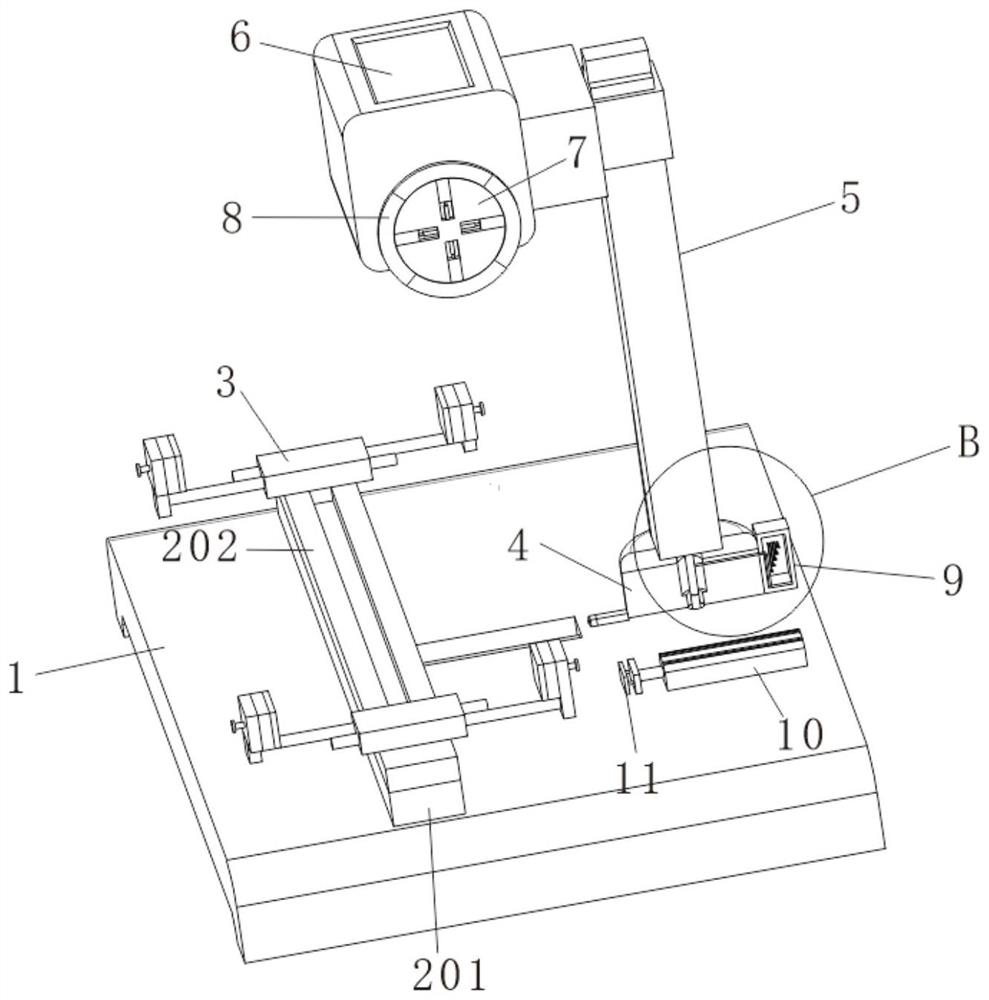

[0028] The present invention provides a technical solution: a rotary cutting machine, please refer to figure 1 with figure 2 , including base 1, mounting base 2 and fixture 3;

[0029] The mounting base 2 is installed on the front side wall of the top of the base 1, and the two sets of fixtures 3 are respectively installed on the left and right side walls of the top of the mounting base 2, and the workpiece is placed above the mounting base 2 and fixed by the clamps 3;

[0030] Base 1 top rear side wall is equipped with support 4, and support 4 top wall is equipped with mounting frame 5, and mounting frame 5 front side walls are equipped with cutting equipment 6, and cutting equipment 6 can slide on mounting frame 5 front side walls, with To move up and down with the blade 8 to realize the cutting and processing of the workpiece, the output shaft on the right side of the cutting device 6 is equipped with a connecting plate 7, and the outer wall of the connecting plate 7 is m...

Embodiment 2

[0035] see figure 1, on the basis of Embodiment 1, a guide groove 12 is provided on the top wall of the base 1, a guide block is installed on the bottom wall of the mounting seat 2, and the guide block is slidably inserted into the inner cavity of the guide groove 12, and the outer wall of the guide block and the rotating rod A connecting rope 13 is installed between the 18 outer walls, and the cutting device 6 rotates so that when the rotating rod 18 is rotated, the connecting rope 13 will also be wound on the outer wall of the rotating rod 18, so that the guide block slides in the inner cavity of the guide groove 12, Pull the mounting seat 2 backward to reduce the distance between the mounting seat 2 and the support 4, and make the workpiece move closer to the blade 8, further ensuring that the cutting machine after rotation can directly process the workpiece, and the rear side of the guide block The wall is equipped with an installation sleeve, and the front end of the conn...

Embodiment 3

[0040] see figure 1 with figure 2 , on the basis of Embodiment 1, the mounting seat 2 includes a mounting plate 201 connected to the top wall of the guide block, the top wall of the mounting plate 201 is provided with a slot, and the top of the slotted cavity is slidingly inserted with a moving seat 202, and the moving seat 202 It is fixed on the top of the mounting plate 201 by bolts, and the height of the fixture 3 can be adjusted by sliding the movable seat 202 in the grooved inner cavity. The guide chute, the bottom end of the clamp 3 is slid and inserted into the inner cavity of the guide chute, so that the distance between the two sets of clamps 3 can be adjusted;

[0041] Compared with the first embodiment, components such as the mounting plate 201 and the moving seat 202 are added, so that the height of the clamps 3 and the distance between the clamps 3 can be adjusted.

[0042] Working principle: Put the workpiece on the top of the mounting base 2 and fix it by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com