Polishing equipment for large-aperture optical element

A technology of optical components and large aperture, applied in optical components, grinding/polishing equipment, optics, etc., can solve the problems of clamping and transporting vacuum tank strength of large aperture optical components, and achieve the effect of ensuring strength and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

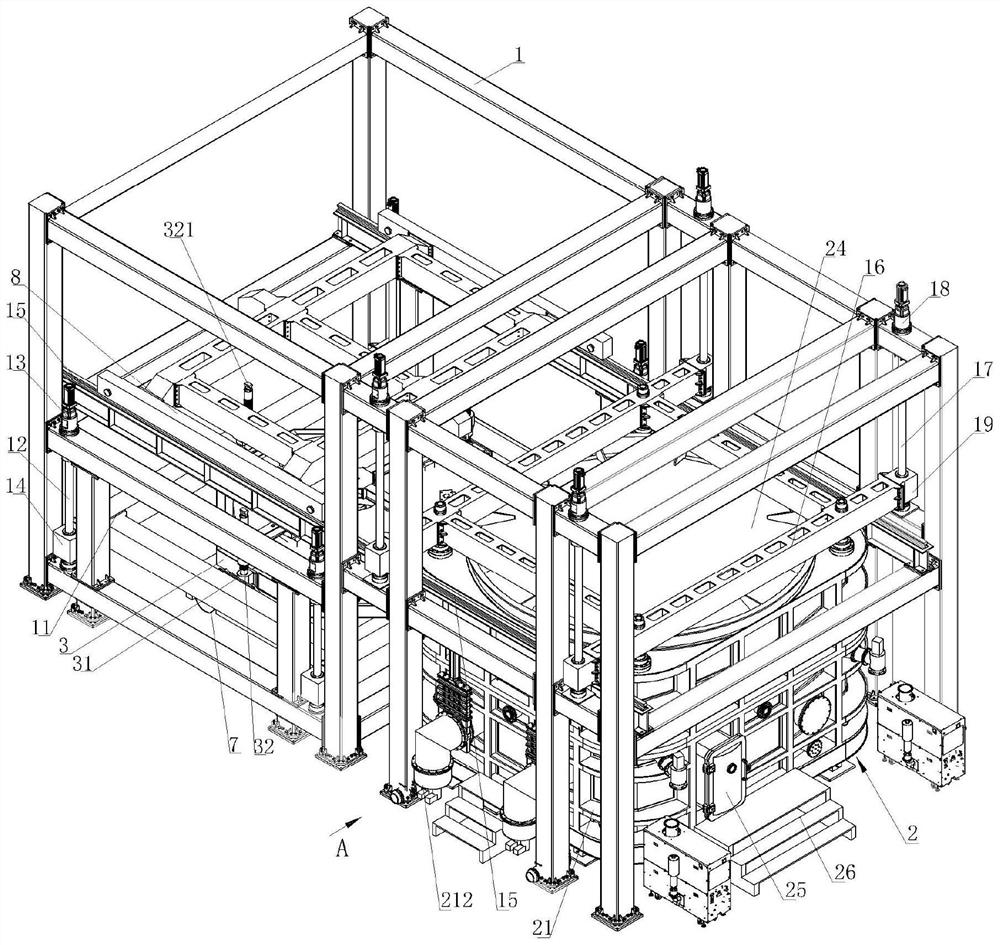

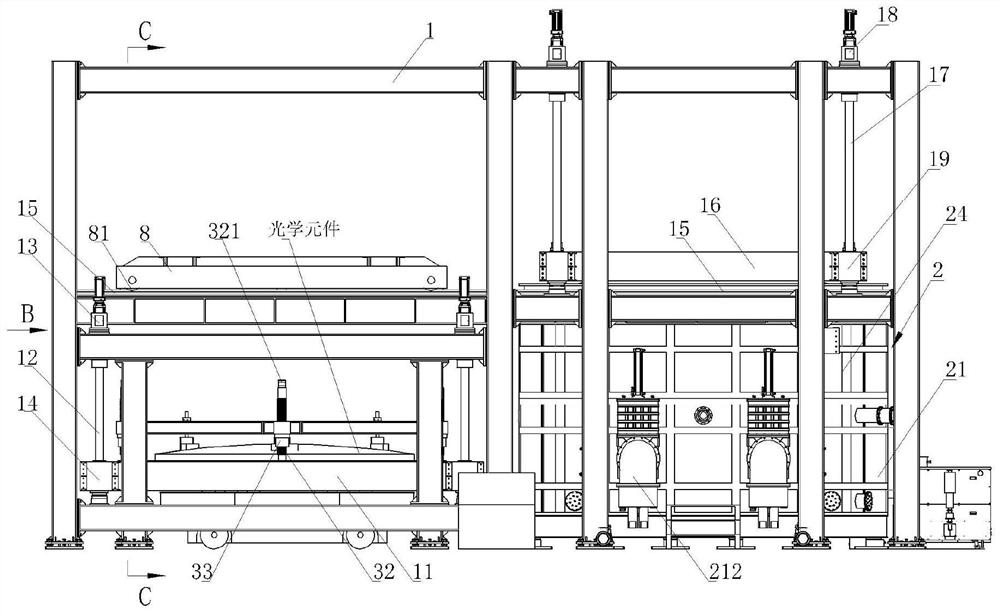

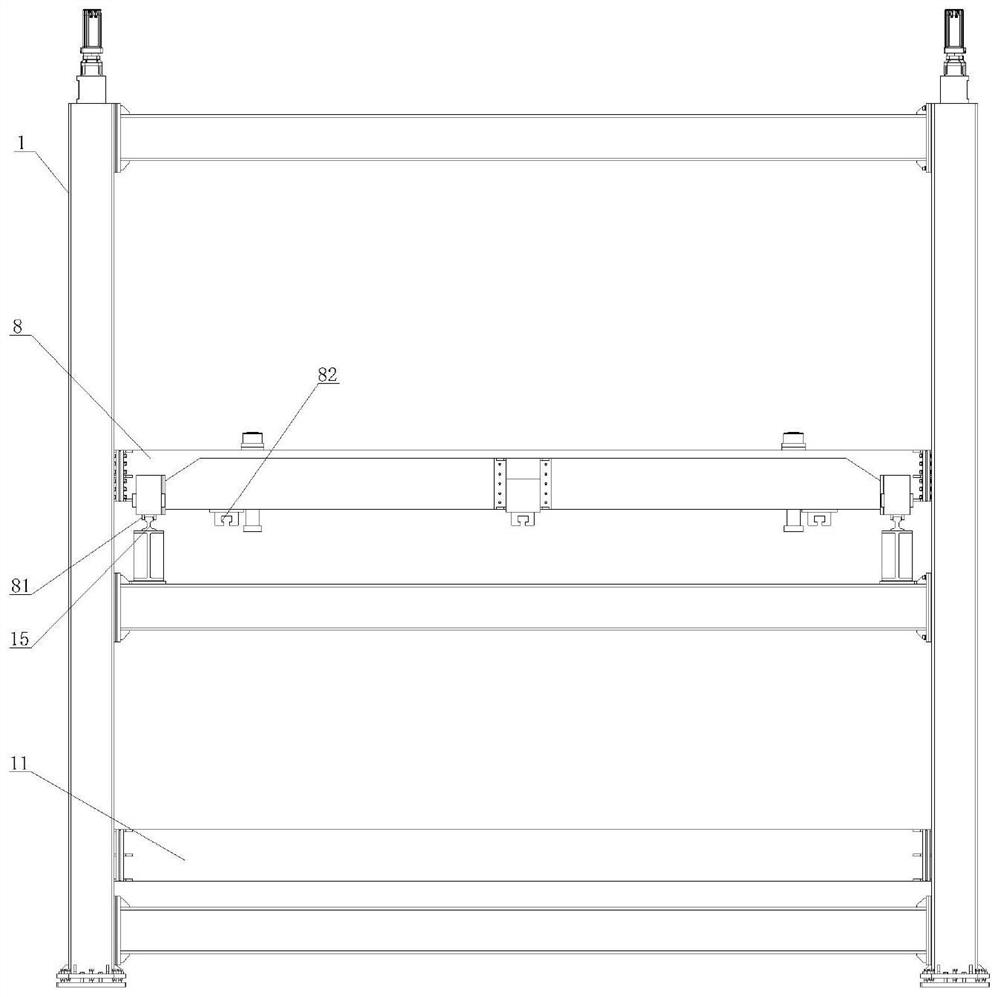

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the polishing equipment for large-diameter optical elements of the present invention includes: a transfer frame 1, in which a lifting frame 11, a positioning tool and a vacuum tank 2 are arranged, and the lifting frame 11 is arranged on the In the transfer frame 1, the first lifting mechanism includes: a first screw rod 12, a first reduction motor 13 and a first nut 14, and four first screw rods 12 are rotated on the transfer frame 1 positioned around the lift frame 11, On the four first screw rods 12, a first reduction motor 13 is respectively connected, and on the four first screw rods 12, a first nut 14 is threaded respectively, and the elevating frame 11 is connected with the four first nuts 14. When the reduction mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com