Self-processing vaccine glass bottle

A glass bottle, processing technology, applied in the field of vaccine glass bottles, can solve the problems of labor and energy consumption of staff, easy to cause omissions, heavy vaccination work, etc., and achieve the effect of reducing infection risk and reducing personnel operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

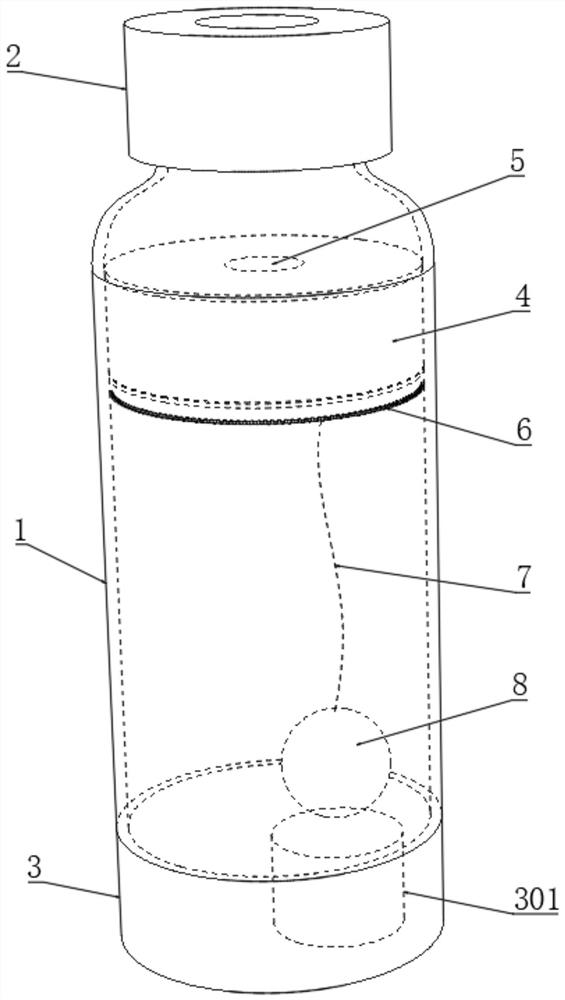

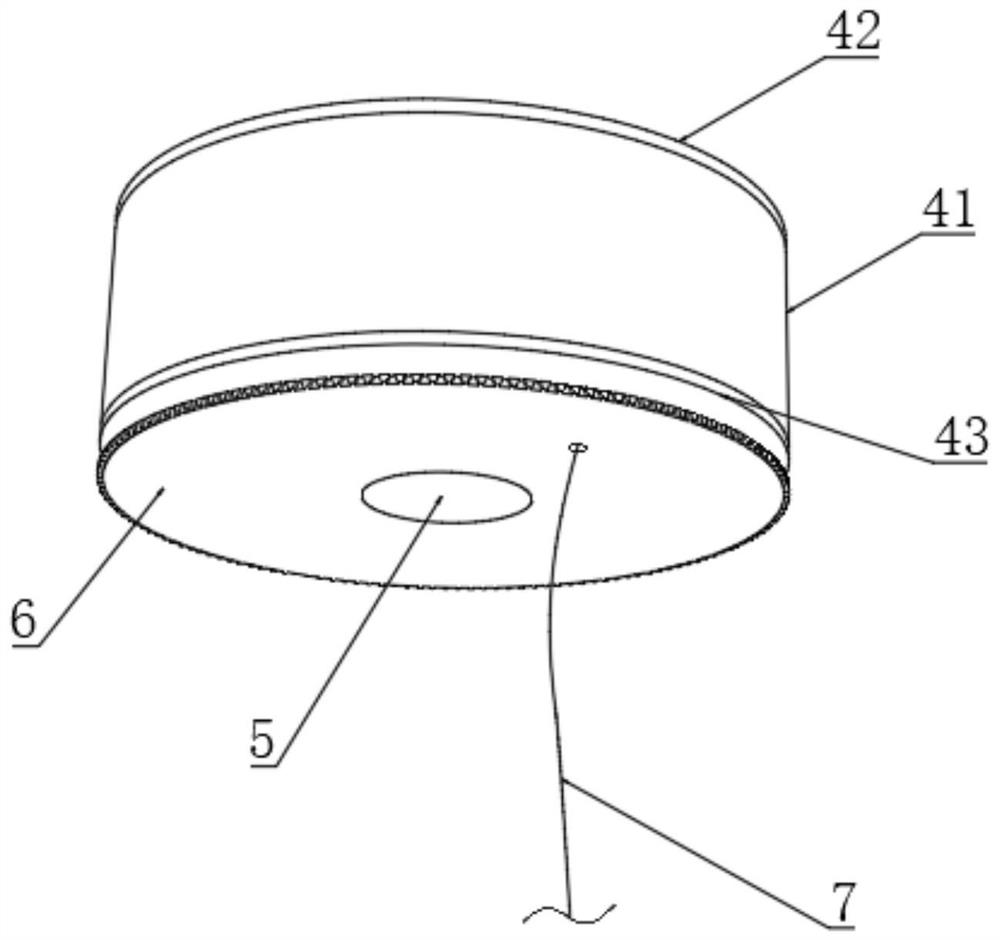

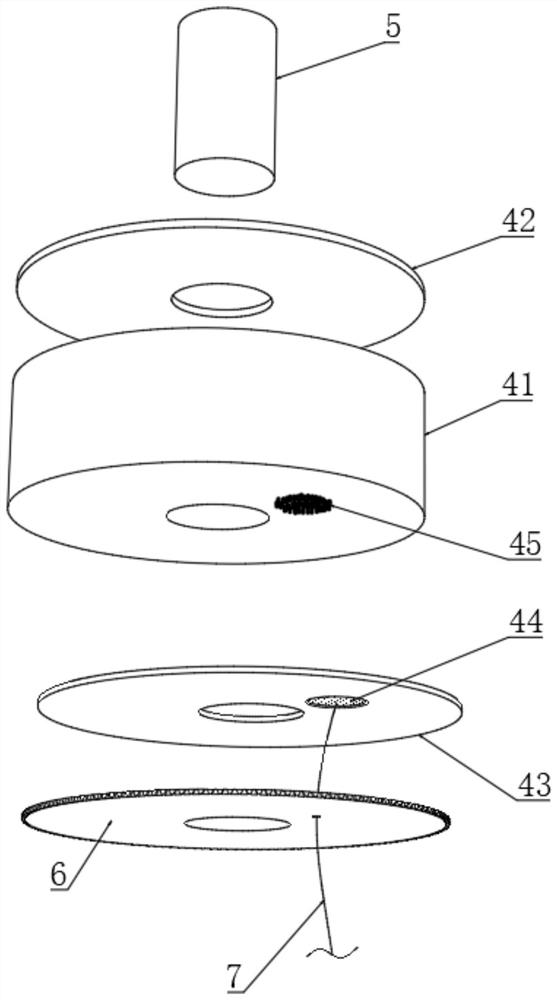

[0046] see figure 1 , a self-processing vaccine glass bottle, comprising a bottle cap 2 and a bottle body 1 filled with vaccine liquid, the bottle cap 2 is fixedly connected to the upper end of the bottle body 1, the lower end of the bottle body 1 is fixedly connected to a bottle seat 3, and the bottle body 1 The interior of the disinfection capsule 4 and the deflector 6 are fixedly connected, the deflector 6 is located at the lower side of the disinfection capsule 4, the interior of the disinfection capsule 4 is fixedly connected with a puncture plug 5, and the lower end of the puncture plug 5 runs through the deflector 6 and fixedly connected with its inside, the lower side of the deflector 6 is provided with a soft floating ball 8, and the outer end of the soft floating ball 8 is fixedly connected with a stretching 7, and the end of the stretching 7 away from the soft floating ball 8 runs through from bottom to top The deflector 6 is also fixedly connected with the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com