Rail type mechanical thrombus aspiration catheter

A suction catheter and orbital technology, applied in surgical cutting instruments, medical science, surgery, etc., can solve problems such as clogging of the distal end of the suction catheter, reduce thrombus blockage, reduce blood loss, and improve thrombus suction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

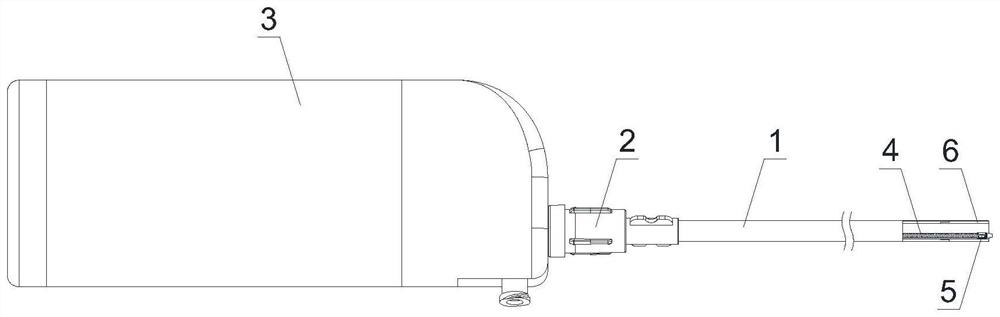

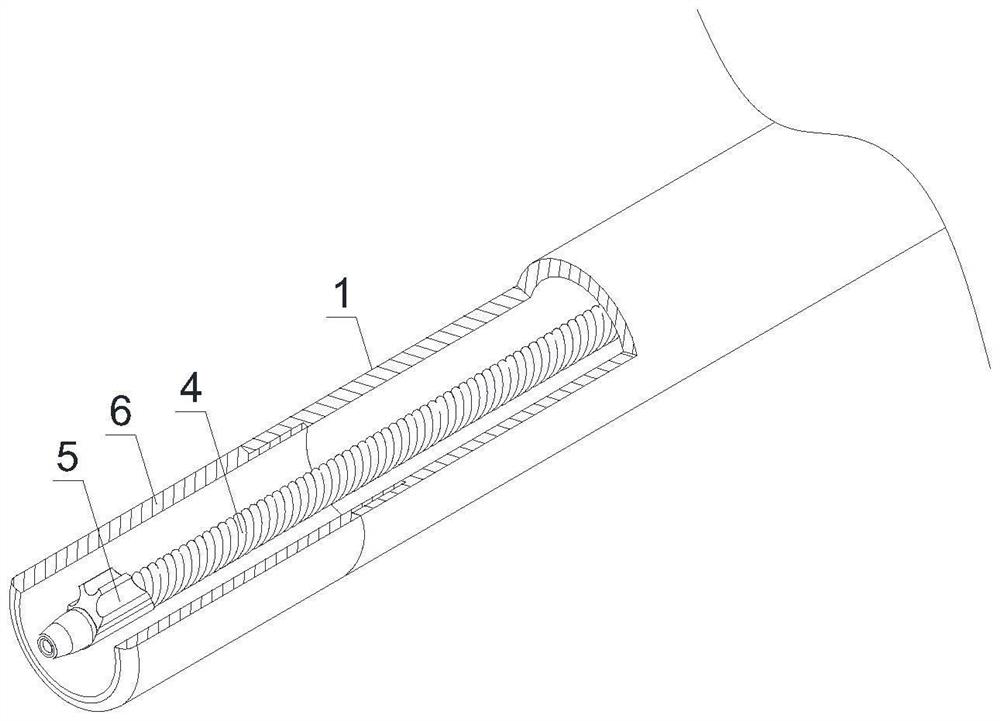

[0047] like Figure 1-Figure 22 As shown, an orbital mechanical thrombus suction catheter includes a suction catheter 1, and the proximal end of the suction catheter 1 is connected with a driving handle 3 through a three-way hemostasis valve 2, and a rotating mechanism is arranged inside the driving handle 3, and the suction catheter 1 is equipped with a transmission shaft 4 and an eccentric metal head 5;

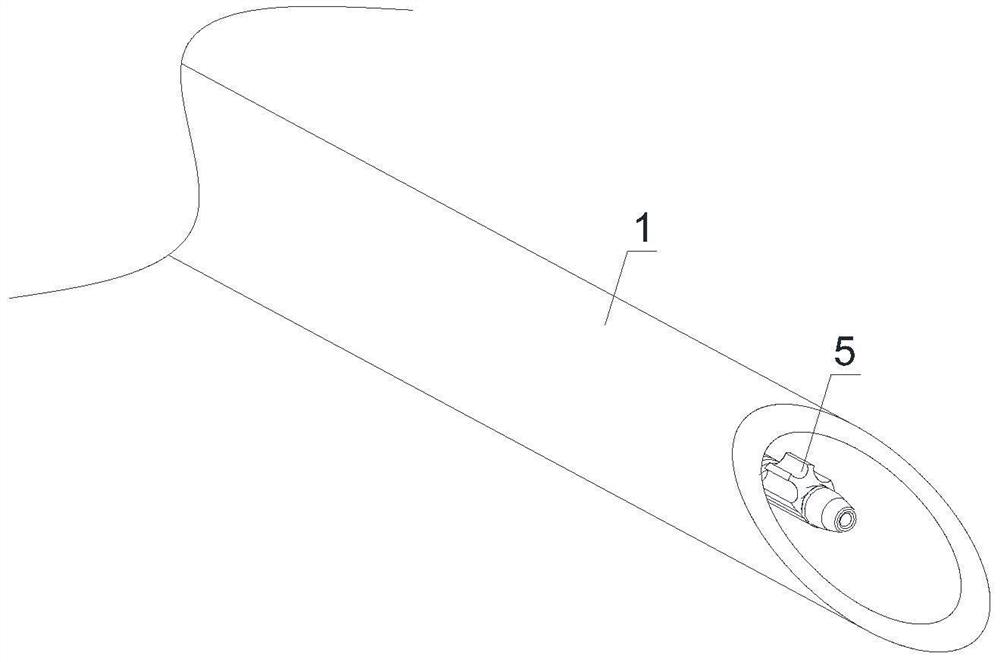

[0048] like Figure 4 As shown, the distal end of the suction catheter 1 is provided with a metal connecting pipe 6;

[0049] like Figure 1-Figure 5 As shown, the proximal end of the transmission shaft 4 passes through the three-way hemostasis valve 2 and is connected to the rotating mechanism in the drive handle 3, and the distal end of the transmission shaft 4 is connected with an eccentric metal head 5, and the center of mass of the eccentric metal head 5 deviates from the rotation axis of the transmission shaft 4 , The eccentric metal head 5 is located in the metal ...

Embodiment 2

[0062] like Figure 16 , Figure 17 As shown, for the hollow transmission shaft 4 and the hollow eccentric metal head 5, the driving handle 3 is designed, and the rotating mechanism inside the driving handle 3 is composed of a motor 301, a driving gear 302, a driven gear 303, A hollow shaft 304 is formed. The motor 301 is connected with a drive gear 302 through a coupling 305. The drive gear 302 is movably installed in the drive handle 3 through a bearing. The driven gear 303 is fixed on the hollow shaft 304. The hollow shaft 304 is movably installed in the drive handle 3 through a bearing. In the driving handle 3 , the driving gear 302 meshes with the driven gear 303 , and the transmission shaft 4 is fixed on the far end of the hollow shaft 304 . The transmission shaft 4 is installed in the distal tube of the hollow shaft 304 with interference fit, and fixed by welding or glue. Other structures are the same as in Embodiment 1.

[0063] The motor 301 in the driving handle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com