Rolling equipment for processing big-leaf tea

A rolling equipment and technology for large-leaf tea, applied in the field of tea rolling, can solve the problems of the degree of pressure of bunched tea leaves, difficult to control, and entanglement of tea meat men, so as to avoid mutual entanglement and bunching, improve efficiency, and enhance the effect of vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

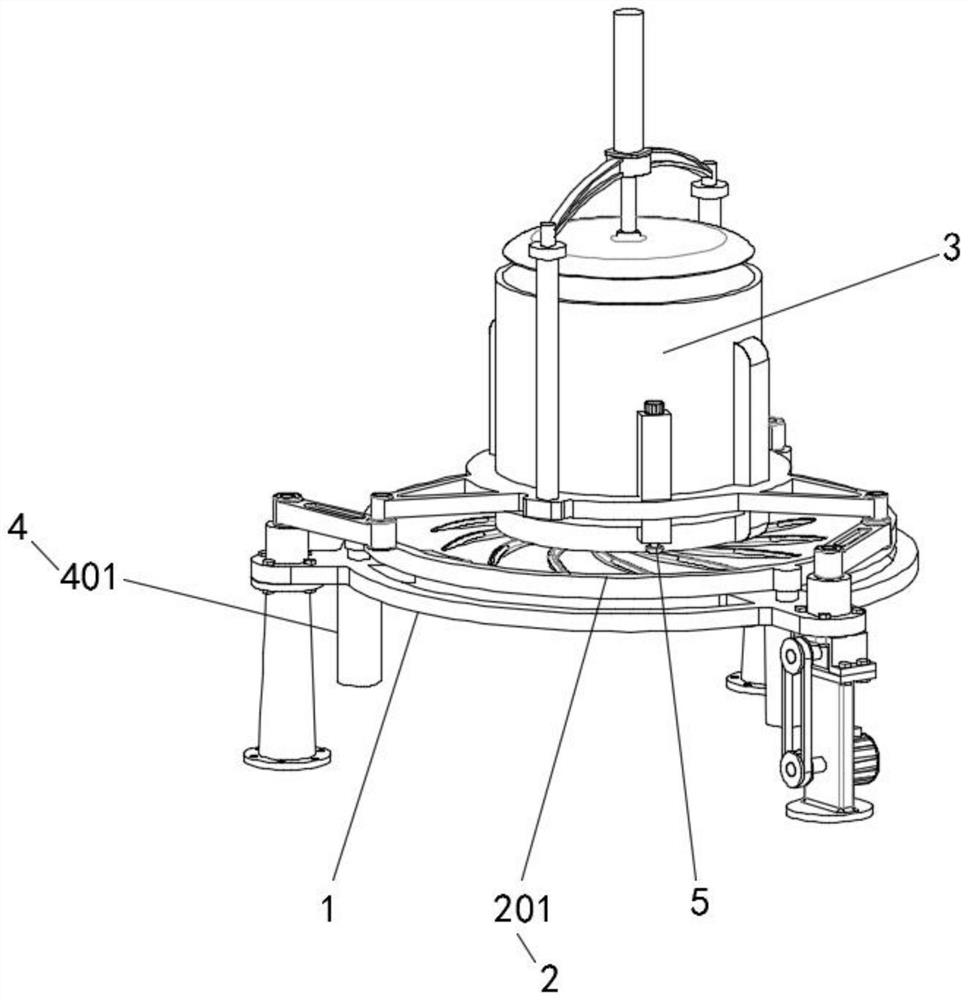

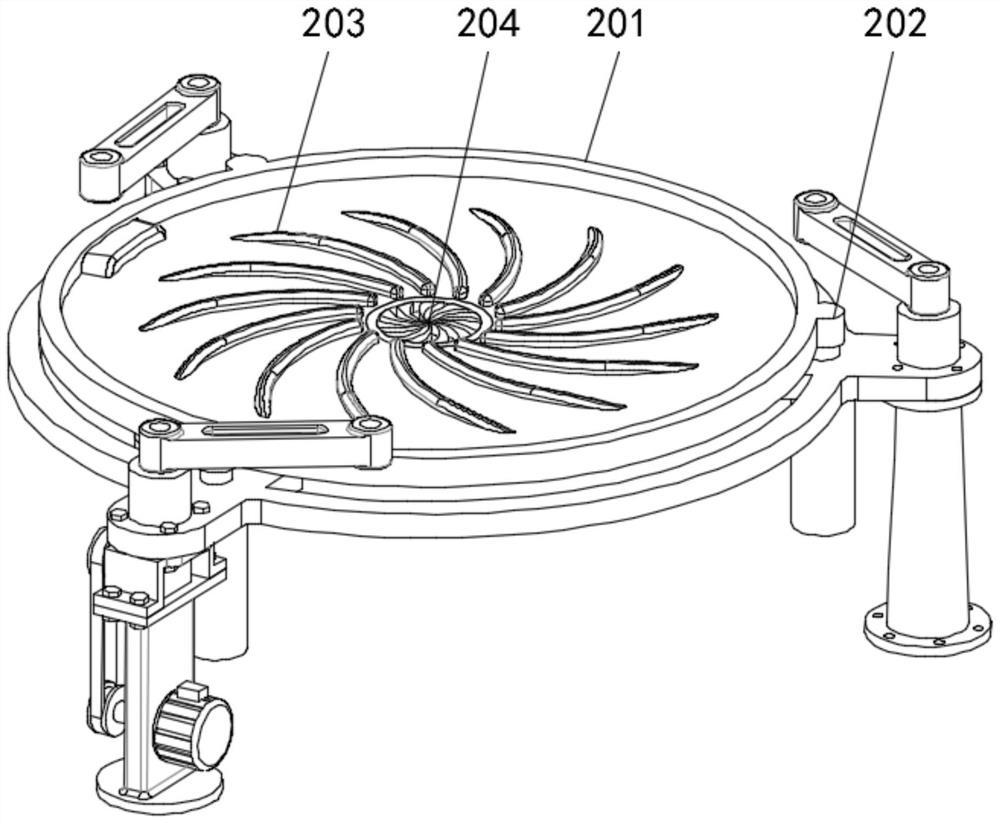

[0039] see Figure 1-2 , a kind of kneading equipment for big leaf tea processing, comprising a mounting frame 1, a kneading plate 2 and a kneading bucket 3, a plurality of firing components 4 are arranged on the lower surface of the mounting frame 1, and the firing components 4 are fixedly installed with the Kneading plate 2, one side of the kneading barrel 3 is provided with a bump 5, and the edge of the inner wall of the kneading plate 2 is fixedly equipped with a power storage block 6 corresponding to the bump 5, and the kneading barrel 3 is The eccentric rotation makes the bump 5 and the power storage block 6 intermittently contact, through the intermittent contact between the bump 5 and the power storage block 6, the firing assembly 4 is charged and then the kneading disc 2 bounce along the direction perpendicular to the upper surface of the kneading pan 2.

[0040]Therefore, during the eccentric rotary motion of the kneading barrel 3, when the bump 5 comes into contact...

Embodiment 2

[0049] Embodiment two: based on embodiment one

[0050] refer to figure 1 and Figure 4 Further, the middle part of the lower surface of the cylinder 401 is penetrated and screwed with an amplitude modulation screw 407, and one end of the amplitude modulation screw 407 is rotatably connected to the lower surface of the first pressure sensor 406 for adjusting the stored force. The amplitude of the firing spring 405 when firing, the other end of the amplitude adjusting screw 407 is fixedly installed with a knob 408 .

[0051] Thus, by turning the knob 408, the amplitude modulation screw 407 is rotated and continuously enters the cylinder 401, and then the first pressure sensor 406 is driven to continuously squeeze the spring seat 403, so that the spring seat 403 compresses the power-storage firing spring 405, changing the power-storage firing spring The initial force of 405, so that the accumulated force of the stored force firing spring is greater when it is compressed again,...

Embodiment 3

[0056] Embodiment three: based on embodiment one and embodiment two

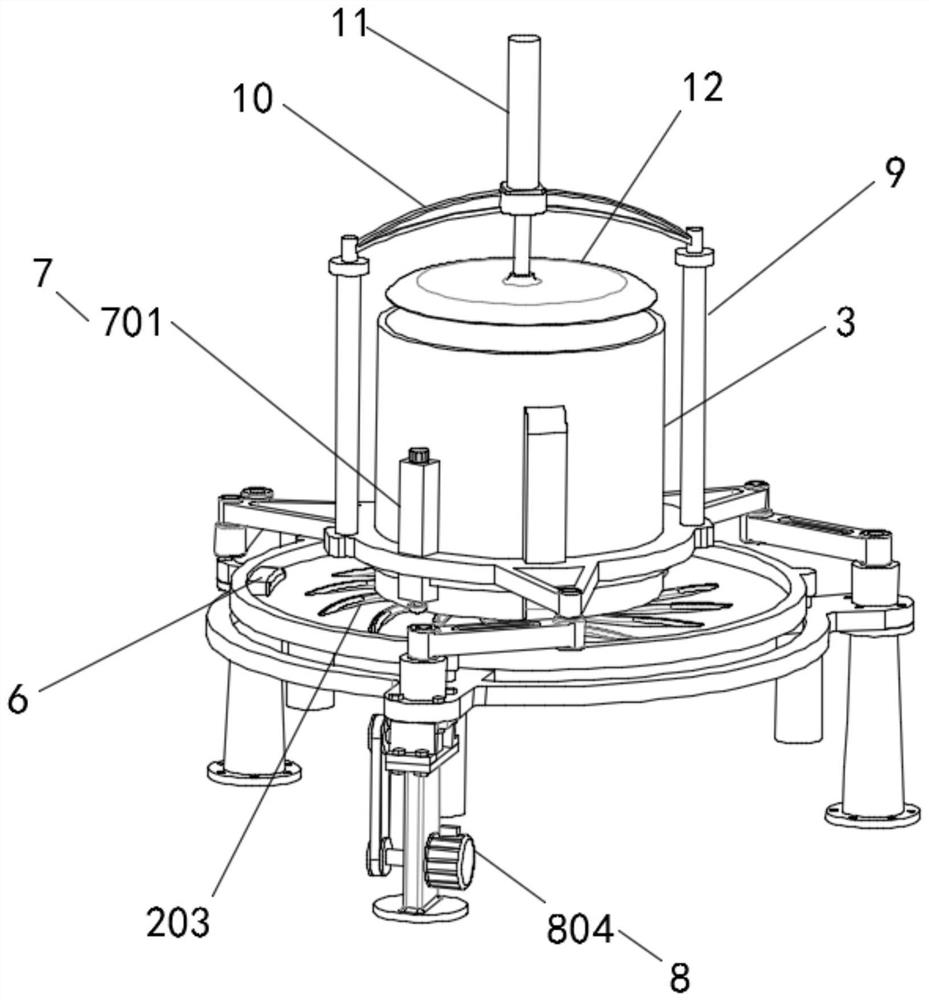

[0057] refer to figure 2 and Figure 5-7 Further, a column 9 is fixedly installed on the upper surface of the clamping frame 801, an arched beam 10 is fixedly installed on the top of the column 9, and an electric telescopic rod 11 is fixedly installed on the upper surface of the arched beam 10, The output shaft of the electric telescopic rod 11 passes through the arched beam 10 and is fixedly installed with a barrel cover 12 .

[0058] Both sides of the inner wall of the kneading bucket 3 are provided with lifting grooves 13, and the lifting grooves 13 are slidably connected with a driving block 14, and one side of the driving block 14 extends into the inner cavity of the kneading bucket 3. An amplifying spring 15 is fixedly installed on the lower surface of the drive block 14, a spring plate 16 is fixedly installed on one end of the amplifying spring 15, and a second pressure sensor 17 is fixedly install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com