Assembly for hybrid drivetrain of motor vehicle

A hybrid power and power train technology, which is applied to the arrangement of multiple different prime movers, power units, vehicle components, etc. of the general power plant, which can solve problems such as trouble and unbalance compensation, and achieve a high degree of flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

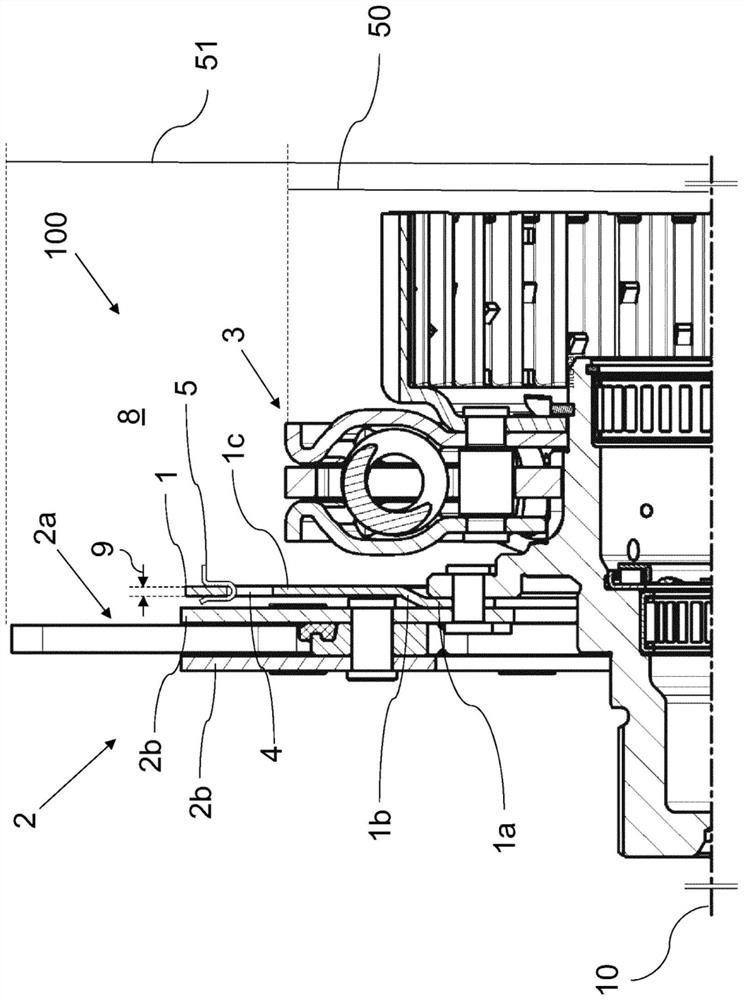

[0032] figure 1 An assembly according to an embodiment of the invention is shown in cross-section.

[0033] exist figure 1 Assembly 100 is shown in detail in . The assembly 100 has a vibration absorber 2 with a simply stacked centrifugal weight 2a, which is guided by means of a track plate 2b. The output of the vibration absorber 2 is connected in a torque-transmitting manner to the input of a torsional damper 3 , which is constructed in a known manner. Above the torsion damper 3 there is an installation space 8 in which the electric motor is to be arranged. In this case, the radial extension 51 of the vibration absorber 2 is greater than the radial extension 50 of the torsional damper 3 .

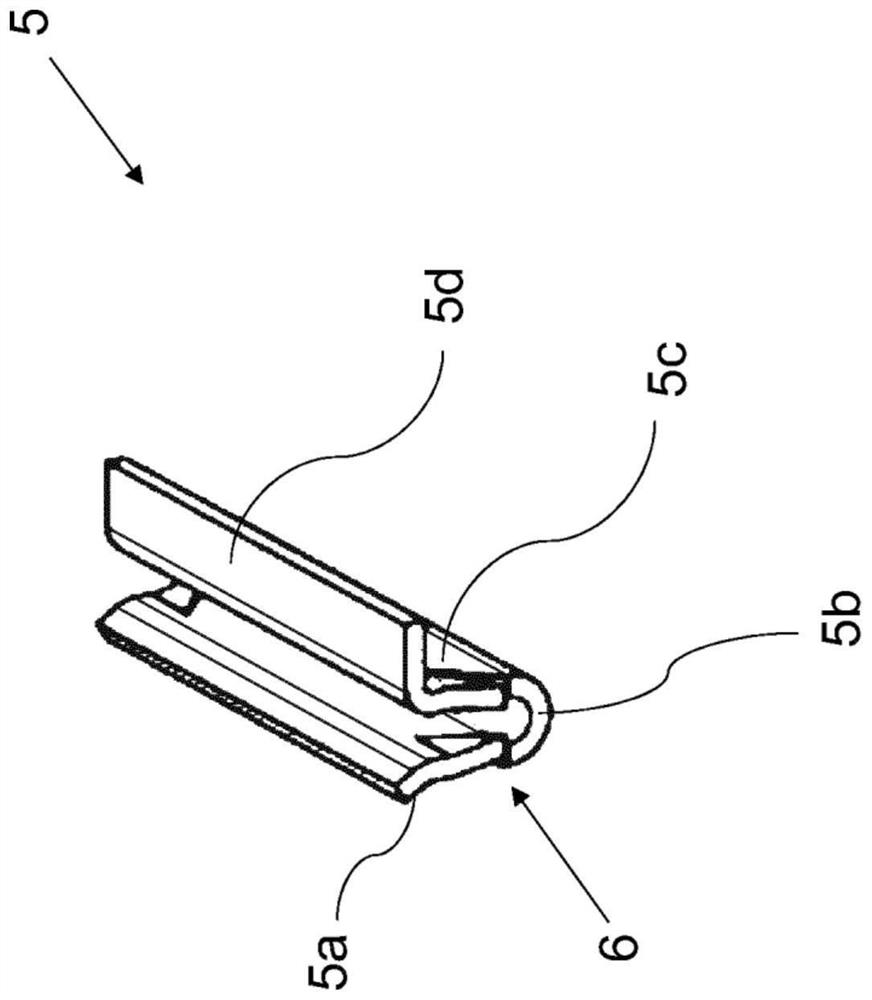

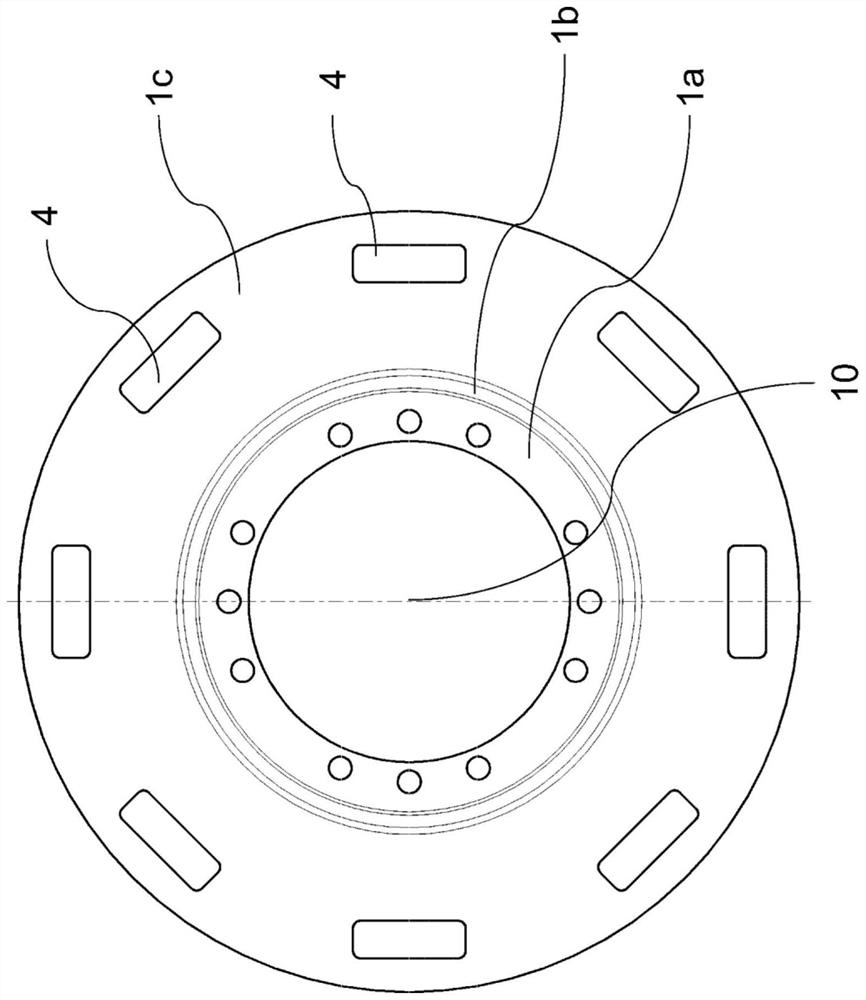

[0034] For the axial spacing of the vibration absorber 2 and the torsional damper 3 , a spacer 1 , which is formed with a corresponding axial thickness 9 , is arranged between the vibration absorber 2 and the torsional damper 3 . In this case, the spacer 1 is annular and, like the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com