Tobacco lamina rating method and system

A technology of laminar tobacco and tobacco leaves, which is applied in the field of laminar tobacco grading methods and systems, which can solve the problems of large influence of inspectors, time-consuming and labor-intensive methods, and the difficulty of automatic identification and clamping, etc., to achieve an easy-to-achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

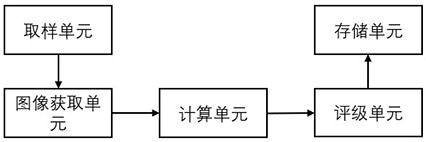

Image

Examples

Embodiment

[0033] A kind of laminar cigarette rating method of the present embodiment, its flow process comprises:

[0034] S1. Take a tobacco leaf sample and spread the tobacco leaf sample flat. Tobacco leaf samples are generally fragmented lamellar tobacco, and the purpose of tiling is to make the calculation of the area ratio of various colors accurate, and to avoid the calculation error of the area ratio caused by partial fragments being covered.

[0035] S2. Acquiring image data of the tobacco leaf sample after being tiled. Specifically, the image data of the tobacco leaf sample can be captured from the top of the laid tobacco leaf sample using an image acquisition device.

[0036] S3. Obtain the area ratios of various basic colors and non-basic colors of the tobacco leaf sample in the image data. In the case of tiling, the area ratios of the various colors of the tobacco leaves can represent the weight ratios of the various colors of the tobacco leaves, so that there is no need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com