Automatic centering control system with self-adaptive line adjustment function

An adaptive adjustment and automatic centering technology, which is applied in the direction of using feedback control, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve lagging adjustment errors, manual wheel centering operations complex, etc. problem, to achieve the effect of improving accuracy, reducing operation difficulty and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

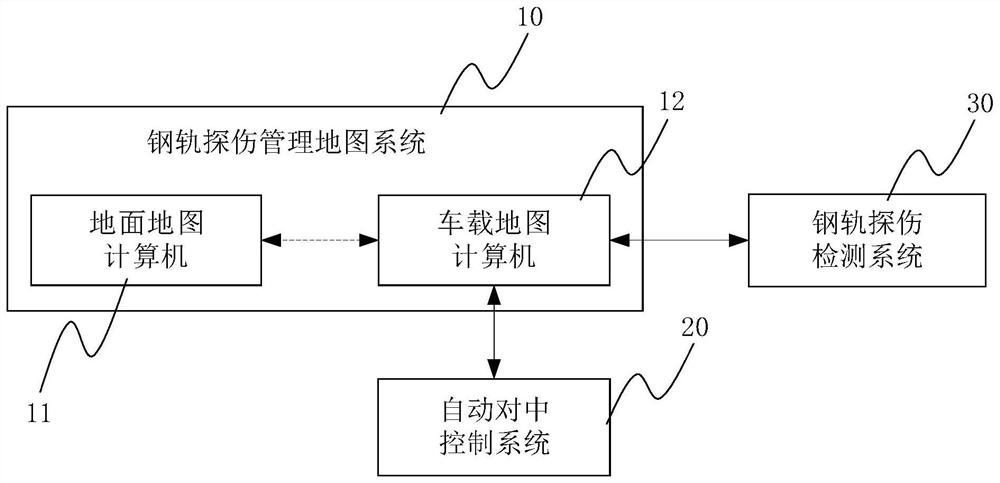

[0069] as attached figure 1 As shown, an embodiment of the automatic centering control system for line self-adaptive adjustment of the present invention is applied to adaptive open-loop control. It is used for flaw detection when part of the line is covered by heavy snow. The labor intensity of the operator is reduced, and the phenomenon of missed inspection of the rail flaw detection vehicle is reduced.

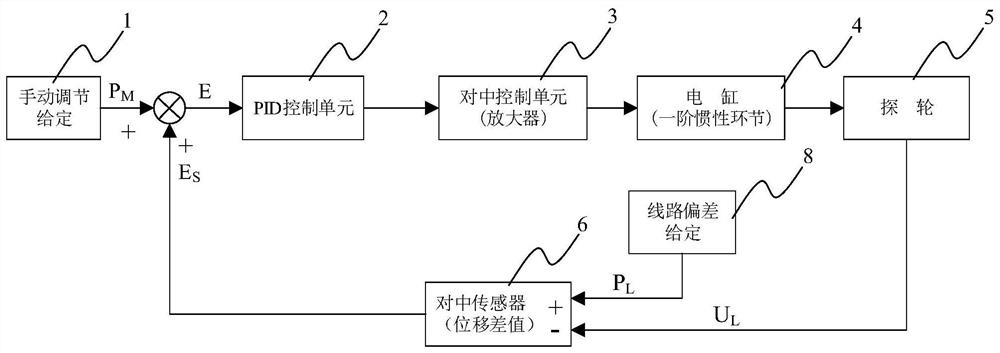

[0070] The automatic centering control system for line adaptive adjustment specifically includes: rail flaw detection management map system 10, automatic centering control system 20 and rail flaw detection detection system 30. The rail flaw detection management map system 10 includes a ground map computer 11 and a vehicle map computer 12 . The ground map computer 11 enters the parameters of the railway line curve, calculates the positive vector value L of the line curve, and uses it as the centering deviation given value P L . as attached Figure 4 As shown, assuming tha...

Embodiment 2

[0073] as attached figure 1 As shown, an automatic centering control system for line self-adaptive adjustment of the present invention is applied to an embodiment of the automatic centering control mode, which is used for issuing flaw detection plan tasks, and the sample TG0 of the recorded automatic centering control parameter table is obtained, and the rail flaw detection (B type map) playback analysis system calls the ground map computer 11 to realize the linkage of the map running path and the automatic centering control parameter table TG1 to perform damage detection, analysis and positioning.

[0074] The automatic centering control system for line adaptive adjustment specifically includes: rail flaw detection management map system 10, automatic centering control system 20 and rail flaw detection detection system 30. The rail flaw detection management map system 10 includes a ground map computer 11 and a vehicle map computer 12 . The ground map computer 11 sends the fla...

Embodiment 3

[0077] as attached figure 1 As shown, an embodiment of the automatic centering control system for line self-adaptive adjustment of the present invention is applied to the self-adaptive centering control mode, which is used for flaw detection planning tasks and automatic centering control parameter table sample TG0 distribution, and the automatic centering control system 20. According to the sample TG0 of the automatic centering control parameter table, the automatic centering estimated given value of the self-adaptive adjustment is obtained.

[0078] The automatic centering control system for line adaptive adjustment specifically includes: rail flaw detection management map system 10, automatic centering control system 20 and rail flaw detection detection system 30. The rail flaw detection management map system 10 includes a ground map computer 11 and a vehicle map computer 12 . The ground map computer 11 sends flaw detection plan path and automatic centering control paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com