Self-rotation high-pressure-resistant online closed sampling valve

A high-pressure-resistant, sampling valve technology, applied in the direction of sampling devices, lift valves, valve details, etc., can solve problems such as difficult maintenance, difficult assembly, complex process, etc., and achieve the effect of optimizing processing technology, reducing production costs, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

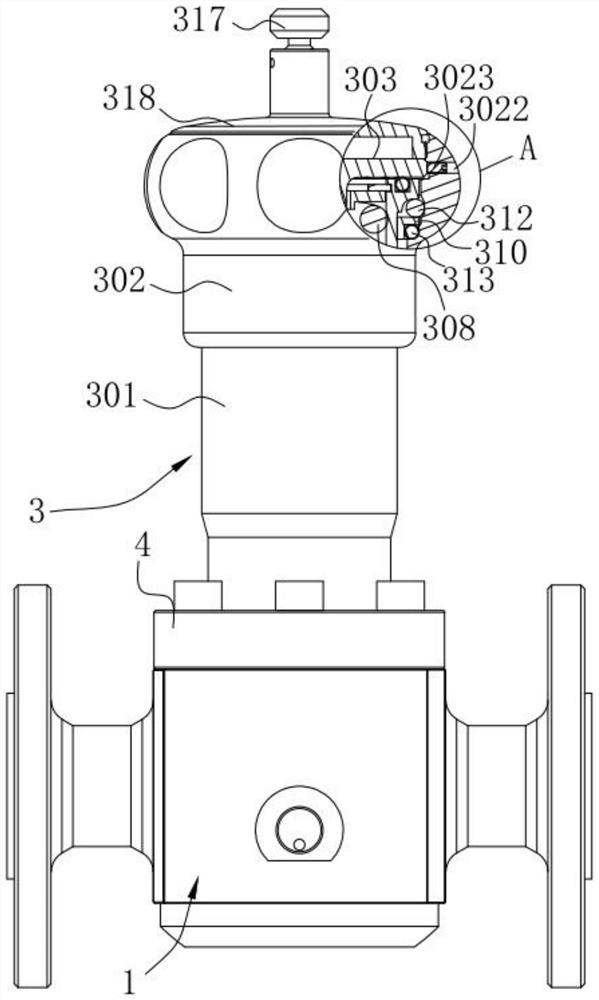

[0041] refer to Figure 1 to Figure 6, The present invention provides a self-rotating high-pressure resistant online hermetic sampling valve, comprising: a valve body 1 , a plunger assembly 2 and an operating mechanism 3 . The valve body 1 is provided with a horizontal valve cavity 101 along the central axis. The valve cavity 101 is open at both ends, and flanges are provided at the openings at both ends, so as to be connected to industrial pipelines. The valve body 1 is provided with a sampling hole 102 at the bottom. The sampling hole 102 is conical with a large diameter at the upper end and a small diameter at the lower end. The sampling hole 102 communicates with the valve cavity 101 and is used to open when sampling is required, so that the medium in the pipeline can be Flow out into the sampling bottle. The plunger assembly 2 is mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com