Clutch assembly with multifunctional lubricating oil circuit and gearbox

A technology for lubricating oil passages and clutches, which is applied to clutches, fluid-driven clutches, and non-mechanical-driven clutches. It can solve the problems of many oil passages, complex machining, and difficulty in processing lubricating oil passages, so as to reduce the difficulty and reduce the number of openings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

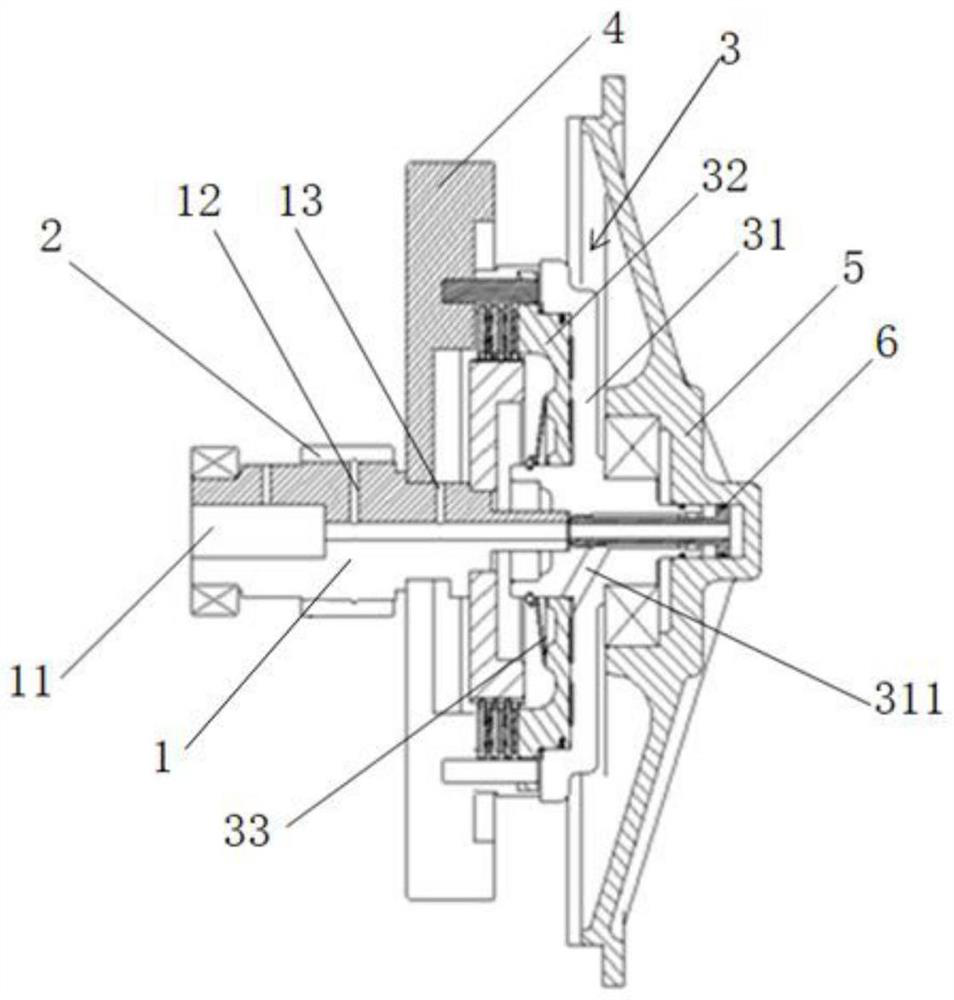

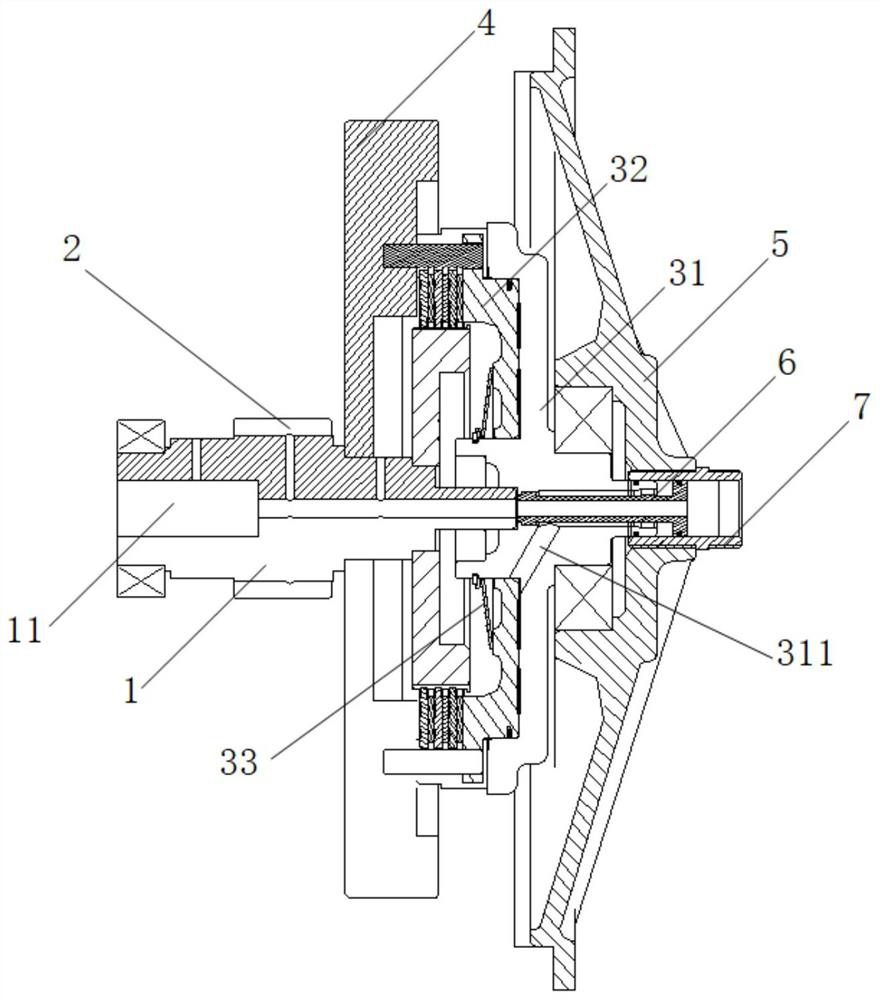

[0034] In the process of manufacturing gearboxes, in order to reduce the difficulty of opening oil passages, reduce the number of oil passages and reduce the difficulty of machining while ensuring lubrication and driving clutch action, such as Figure 1-Figure 2 As shown, the present invention provides a clutch assembly of a multifunctional lubricating oil circuit. The clutch assembly includes: rotating shaft 1, output gear 4, sun gear 2, clutch assembly 3 and lubricating shaft tube 6.

[0035] Wherein, along the axial direction of the rotating shaft 1, there is a lubricating oil channel 11 that runs through itself on the rotating shaft 1, and the lubricating oil channel 11 is coaxially arranged with the rotating shaft 1; the output gear 4 is rotatably arranged on the rotating shaft 1; The wheel 2 is fixed on the rotating shaft 1, specifically, in this embodiment, the sun gear 2 is integrated on the rotating shaft 1; the clutch assembly 3 is fixedly installed on the rotating s...

Embodiment 2

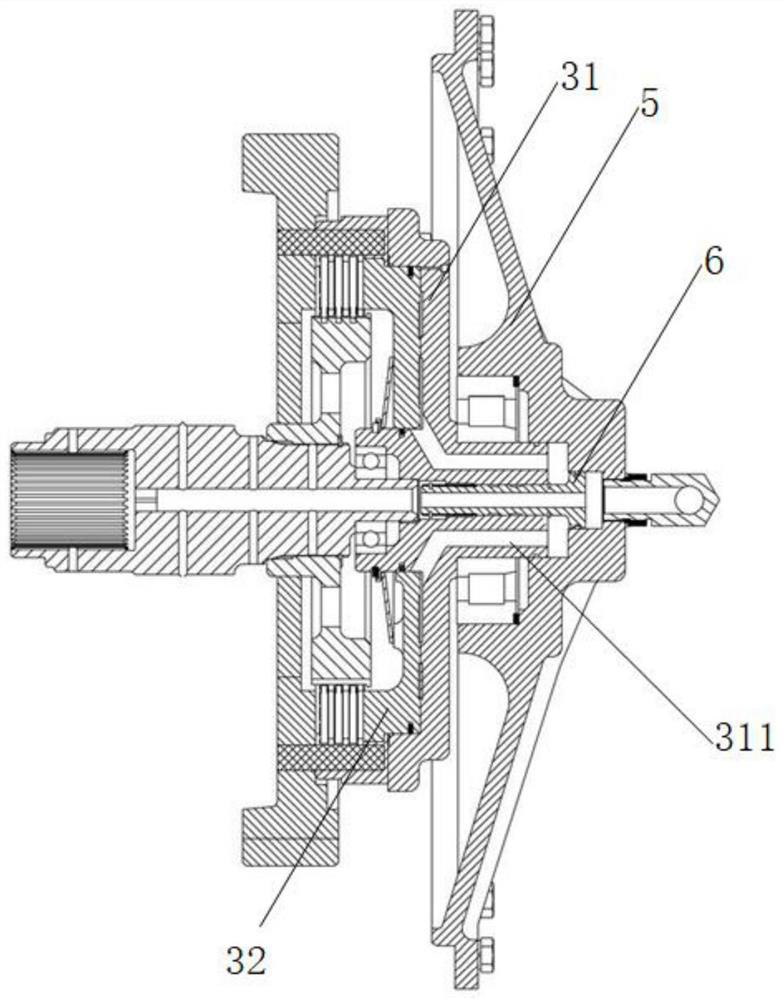

[0046] Such as image 3 As shown, the biggest difference between this embodiment and Embodiment 1 is that, in this embodiment, the lubricating shaft tube 6 can slide along the axial direction of the housing 31 , so as to adjust the pressure of the hydraulic oil pushing the piston 32 . Specific implementation manners are described below.

[0047] Because in the prior art, when putting into gear, the gear position oil channel of transmission valve is opened, and hydraulic oil enters the housing of clutch. When the oil passage valve of the transmission valve is opened, due to the "water hammer effect", the oil pressure increases suddenly, forming a pressure pulse, which pushes the piston 32 to move to the left, so that the steel plate and the friction plate are instantly combined, and there is no sliding friction process, and the gear is put on instantly. . Then, according to the principle of "water hammer effect", the pressure drops rapidly, and the steel plate and the frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com