Framework, bogie and railway vehicle

A bogie and frame technology, which is applied in the field of rail vehicles and can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

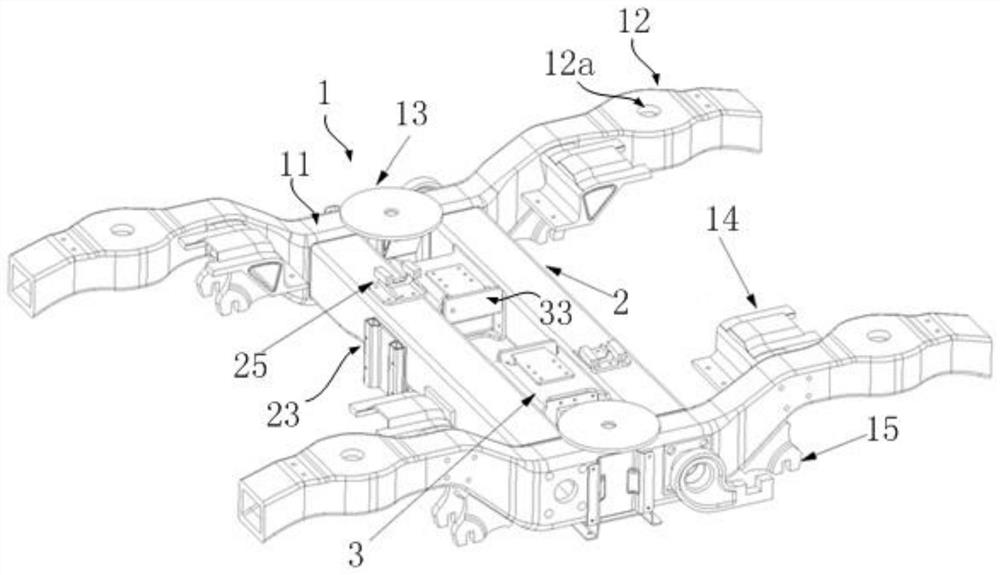

[0107] Please refer to Figure 20 , Figure 20 It is a schematic structural diagram of the bogie frame in Embodiment 2 provided by the present invention.

[0108] The frame structure of embodiment 2 is basically the same as that of embodiment 1, the only difference lies in the structure of the end beam body 12 of the side beam 1, and the same parts will not be repeated.

[0109] Such as Figure 20 As shown, the side beam 1 in Embodiment 2 includes a box-shaped main beam body 11, that is, the main beam body 11 is a hollow box-shaped structure. What is different from Embodiment 1 is that the end beam body in Embodiment 2 12 is a plate structure, specifically, Figure 20 The end beam body 12 is a strip plate structure.

[0110] The plate-shaped end beam body 12 at the end of the side beam 1 is used to connect with a series of springs, and the first series of springs are located below the end beam body 12 . In this way, the main beam body 11 of the side beam 1 is used as the ...

Embodiment 3

[0119] Please refer to Figure 21 , Figure 21 It is a schematic structural diagram of the side beam 1 of the bogie frame in Embodiment 3 provided by the present invention.

[0120] It is basically the same as Embodiment 2, the only difference is that the end beam body 12 is a straight strip plate without bending treatment. When the end beam body 12 is designed to be relatively short, no bending treatment is required, and it can Avoid interference with the vehicle body. The molding process can be understood with reference to Example 2.

Embodiment 4

[0122] Please refer to Figure 22 , 23 , Figure 22 A schematic structural view of the bogie frame in Embodiment 4 provided by the present invention; Figure 23 for Figure 22 Schematic diagram of the middle side beam 1.

[0123]The framework structure of embodiment 2 is basically the same as that of embodiment 2-3, the difference is that the structure of the end beam body 12 and the end beam body 12 and the main beam body 11 are arranged separately, the same parts will not be repeated, and the main differences will be described below part.

[0124] Such as Figure 23 As shown, the main beam body 11 and the end beam body 12 in Embodiment 4 are arranged separately, and the main beam body 11 is made of fiber composite material, and the end beam body 12 is made of metal. The end beam body 12 is also a plate-shaped structure, and its function is the same as that of the plate-shaped end beam body 12 in Embodiments 2 and 3.

[0125] Figure 23 Among them, the end beam body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com