Garbage on-site recycling environment-friendly treatment facility

A technology for environmental protection and garbage disposal, which can be used in garbage bins, garbage collection, packaging, etc., and can solve problems such as increasing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

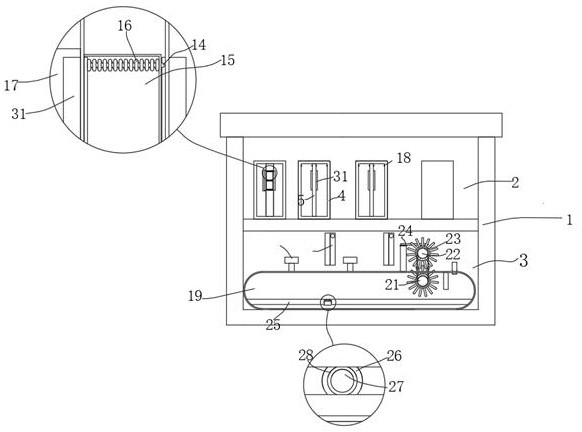

[0031] see Figure 1-3 , the present invention provides the technical solution: a kind of recycling environment-friendly processing facility for garbage in situ, including a garbage room 1, the garbage room 1 is composed of an upper floor 2 and a lower floor 3, and the inner cavity of the upper floor 2 is fixed with four garbage cans 4, four Two garbage bins 4 are divided into recyclable, non-recyclable, harmful and others. The middle part of the garbage bin 4 inner chambers is fixed with a dividing plate 5, and both sides of the dividing plate 5 are fixed with a longitudinal blade 31, only the vertical blade 31 in the recyclable garbage bin. It can shrink, because it needs to be pushed horizontally to push the metal parts accumulated on the concave magnetic plate 7 into the collection pipe 17, and the harmful garbage bin does not contain partitions and longi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com