A lunch box with folded edges and corners and a method of using the same

A lunch box and corner wrapping technology, applied in packaging, biological packaging, sustainable packaging industries, etc., can solve the problems of difficulty in folding and shaping, unstable position of the folding line, and large restoring force of the lower edge, so as to achieve folding The effect of reducing the difficulty of shaping, high assembling convenience, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

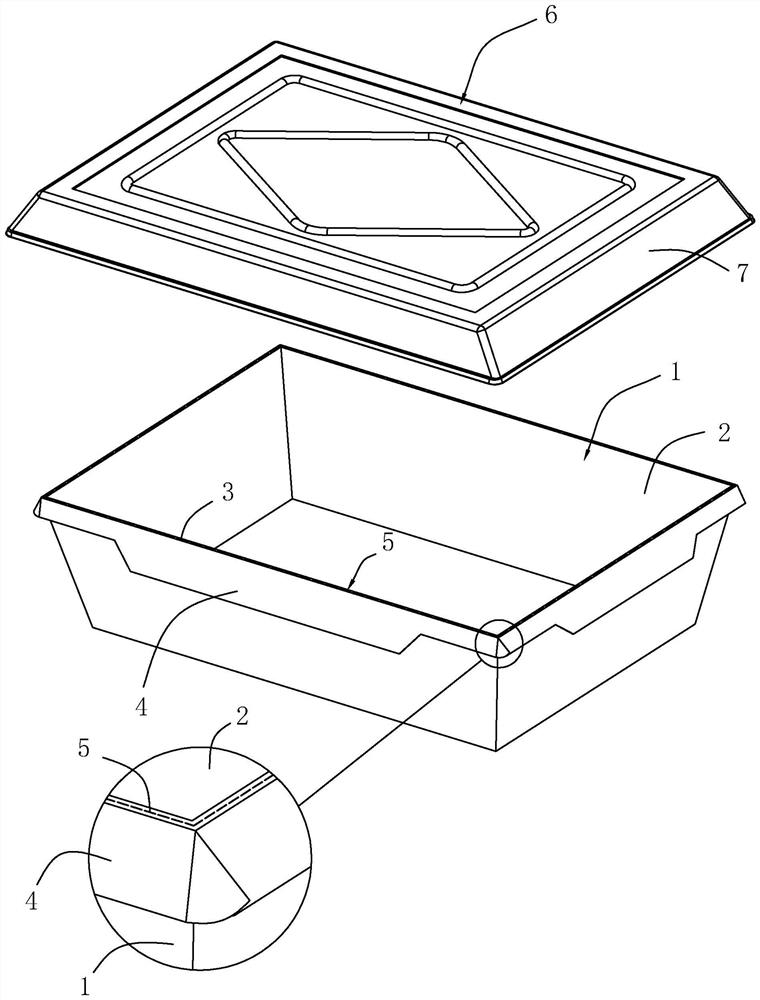

[0053] A lunch box with folded edges and corners, see figure 1 , including the inner box body 1. In this embodiment, the shape of the inner box body 1 is a square structure. The inner box body 1 is provided with a accommodating slot 2, and the inner box body 1 is provided with a box mouth 3. The box of the inner box body 1 Port 3 is set up.

[0054] see figure 1 , the inner box body 1 is provided with a folding piece 4, the folding piece 4 is located at the box mouth 3, the number of the folding piece 4 is four, and the folding point between the folding piece 4 and the inner box body 1 is A folding line 5 is provided, and the folding line 5 is formed by a plurality of through grooves penetrating through the inner box body 1 arranged in a straight line at intervals.

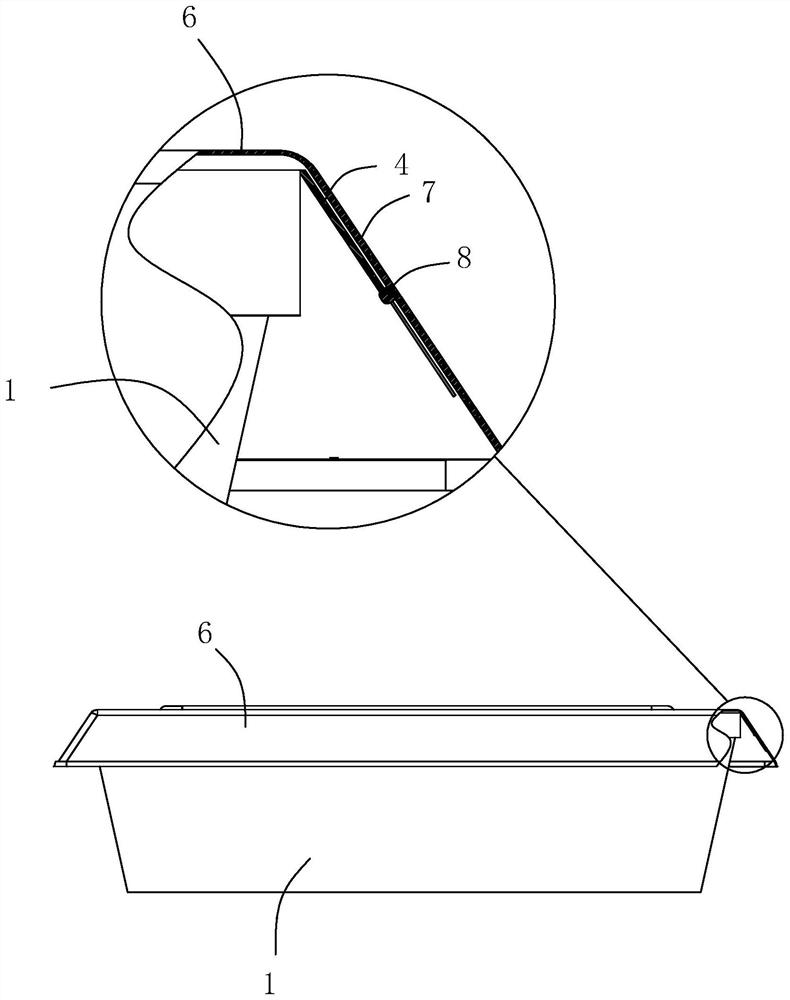

[0055] see figure 1 as well as figure 2 , also includes a box cover 6, the periphery of the box cover 6 is provided with a cover edge 7, and the inner side of the cover edge 7 is provided with a cartridge pro...

Embodiment 2

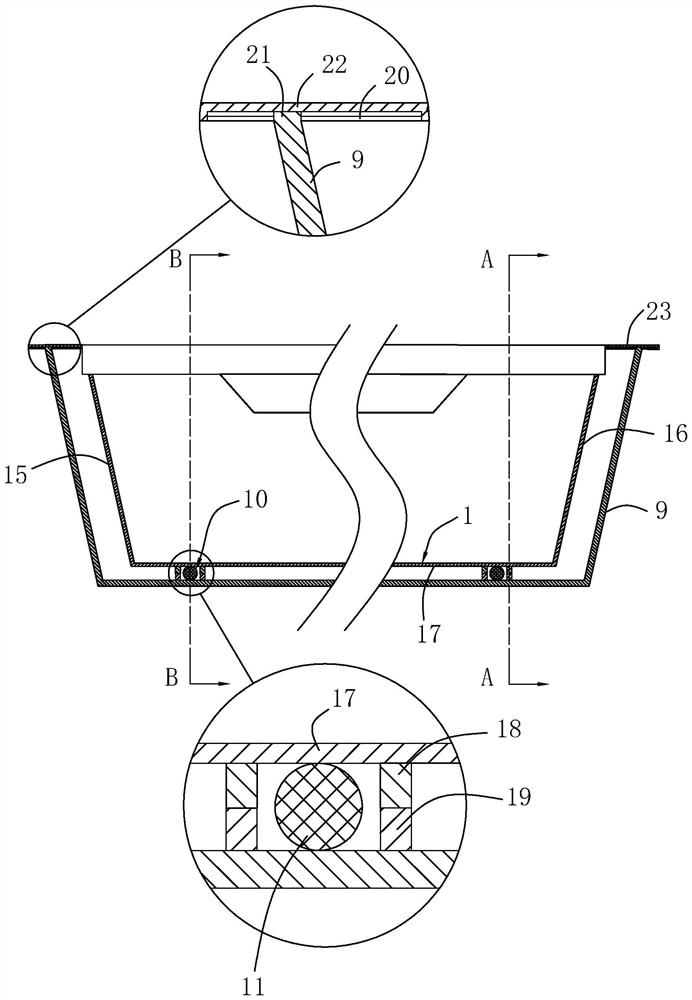

[0058] The difference from Embodiment 1 is: see image 3 , and also includes an outer box body 9 , and the outer box body 9 is sleeved on the outside of the inner box body 1 .

[0059] see image 3 as well as Figure 5 , between the inner box body 1 and the outer box body 9 is also provided with a clamping rod assembly 10, the clamping rod assembly 10 includes three clamping rod segments 11 arranged in separate parts, and two ends of the clamping rod segment 11 are respectively provided with plug The end 111 and the socket 112, the plug end 111 on the clamping rod segment 11 can be inserted into the socket 112 of another adjacent clamping rod segment 11, and a connecting line 12 is connected between the two adjacent clamping rod segments 11.

[0060] see Figure 4 , Figure 5 as well as Image 6 , the outer side wall of the inner box body 1 includes a front side wall 13, a rear side wall 14, a left side wall 15, a right side wall 16, a lower side wall 17, the front side w...

Embodiment 3

[0066] Embodiment 3: On the basis of Embodiment 3, the following structure is added.

[0067] see Figure 7 , in the outer box body 9, there are two fixed components 26, each fixed component 26 includes a devil stick 24, a rotating rod 25, and the two ends of the rotating rod 25 are the trigger end 251 and the bonding end 252, respectively. The middle part is rotatably connected to the inner box wall of the outer box body 9, and the two fixing components 26 are respectively located at the outer box body 9 near the left side wall 15 and the right side wall 16. The devil stick 24 includes a male stick 241, a negative stick 242, the male adhesive sheet 241 is installed on the bonding end 252, and the female adhesive sheet 242 is installed on the lower side wall 17 of the inner box body 1. After the inner box body 1 squeezes the trigger end 251 of the rotating rod 25, the rotating rod 25 is rotated, and the male adhesive sheet 241 of the rotational bonding end 252 is bonded to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com