Automatic welding method for gas delivery pipe support

An automatic welding and gas pipeline technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding precision of gas pipeline bracket, large manual welding error, waste of time, etc., so as to save manpower and avoid false welding , Guarantee the effect of the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

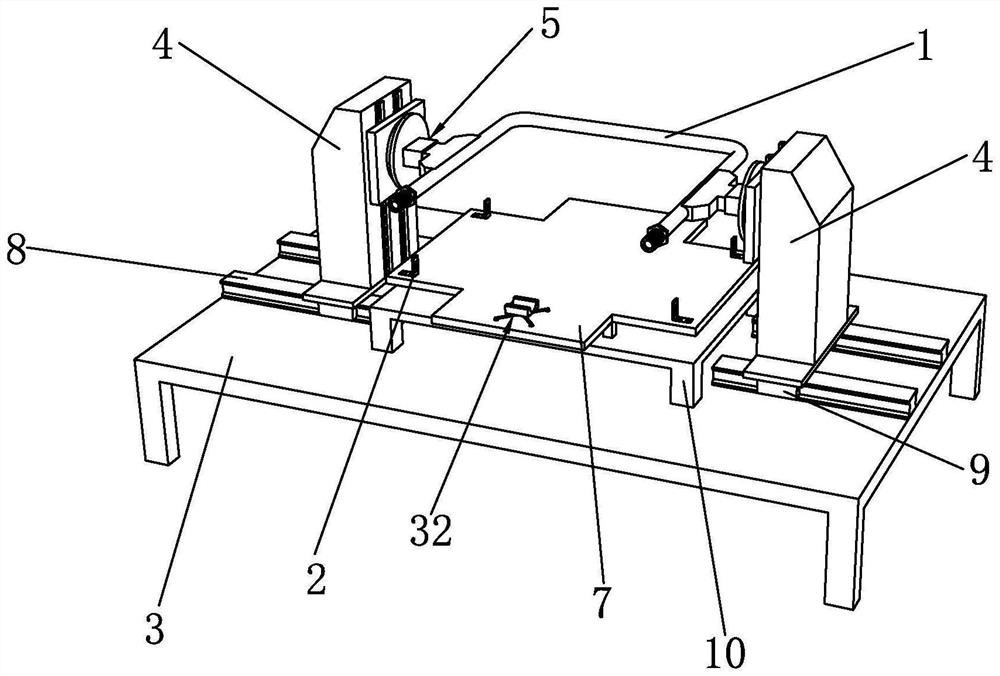

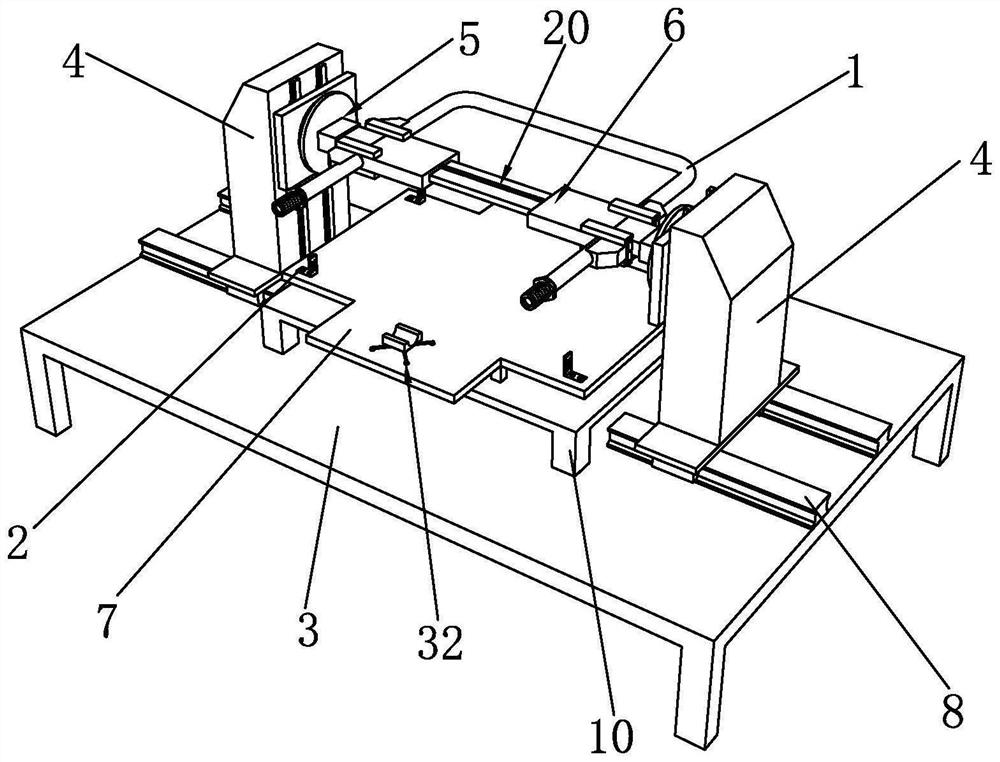

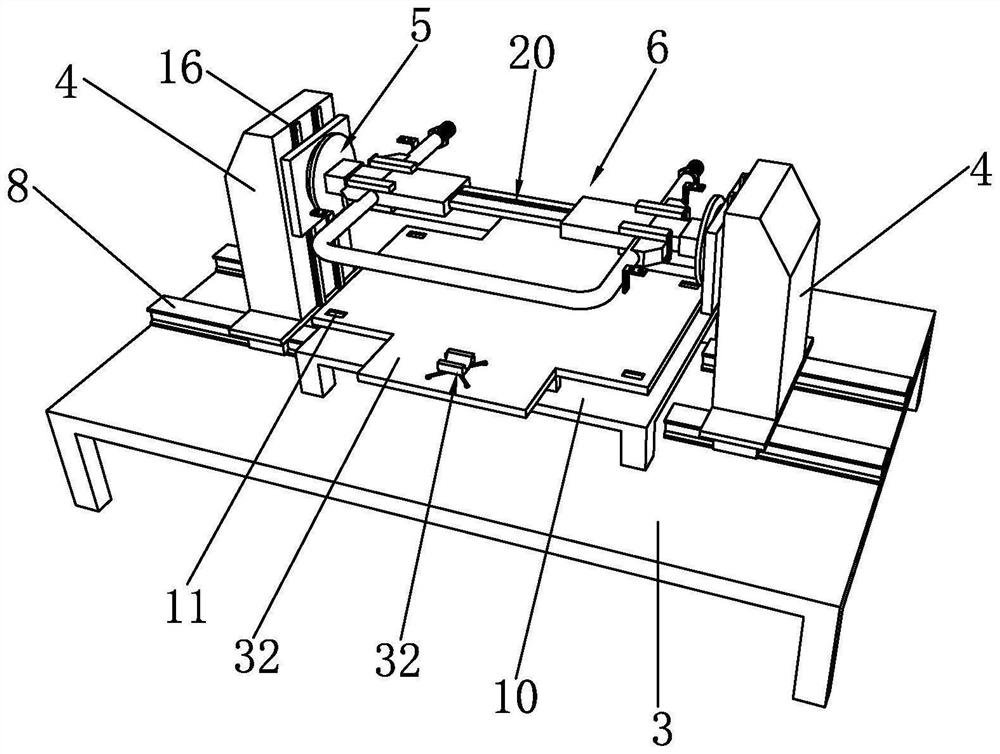

[0043] like Figures 1 to 7 As shown, the automatic welding method of the air supply pipe bracket of the present invention includes the following steps:

[0044] A, preparation before welding

[0045] 1) Workpiece preparation

[0046] First, the air pipe 1 to be welded and the bracket 2 for welding on the air pipe 1 is first prepared, and then the air supply pipe 1 to be welded is cleaned with the outer surface of the bracket 2.

[0047] 2) Preparation of welded platform 3

[0048] First, the size of the air supply pipe 1 is measured, and the size is inspected in the mounting range of the fixing assembly of the welded table 3, and then fixed to the bracket 2 on the bracket mounting plate 7 according to the mounting position of the bracket 2, and according to the mounting position of the bracket 2. A support table 10 is provided between the bracket mounting plate 7 and the welded stage 3, and the support table 10 is fixed to the welded stage 3, and the bracket mounting plate 7 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com