Pretreatment equipment and process for high-appearance color anodized aluminum alloy die casting

A technology of anodizing and die-casting, which is applied in the direction of electrolytic components, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems affecting the surface forming quality of die-casting parts, and achieve the effect of improving the surface forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

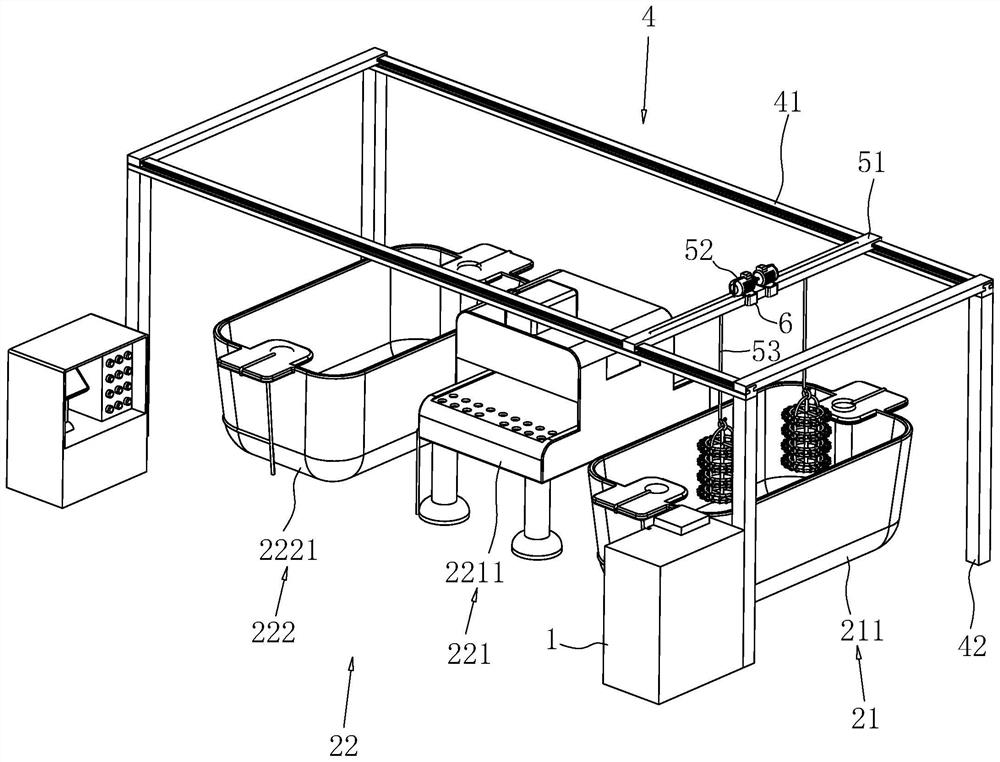

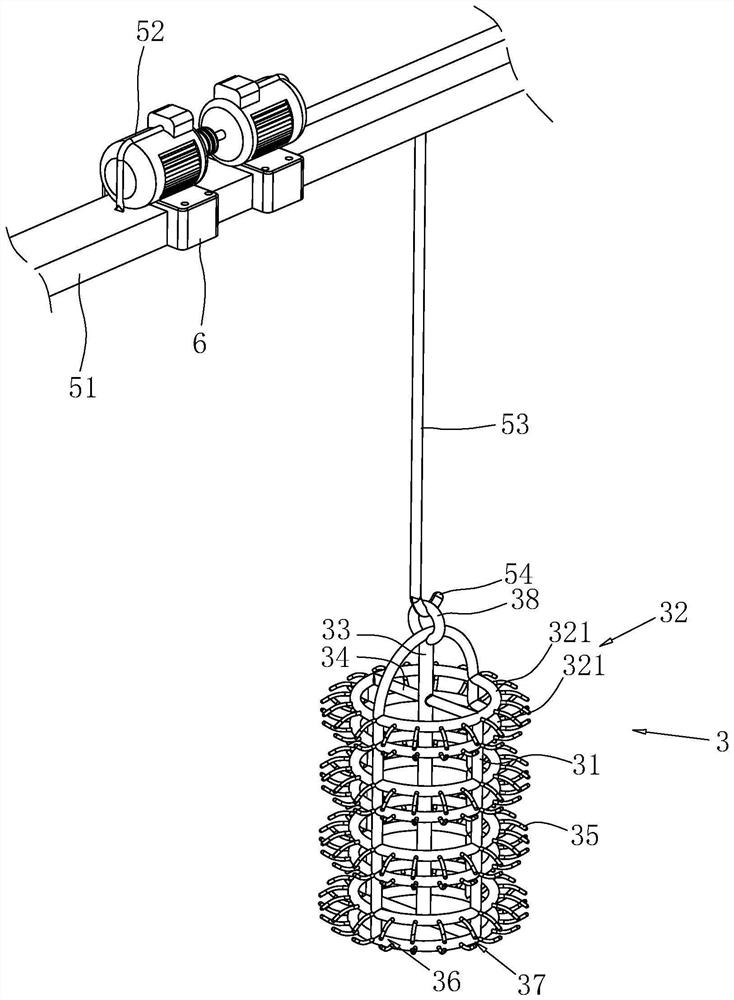

[0037] The following is attached Figure 1-2 The application is described in further detail.

[0038] The embodiment of the present application discloses a pre-treatment equipment for high appearance color anodized aluminum alloy die castings. refer to figure 1The high appearance color anodized aluminum alloy die-casting pre-treatment equipment includes a post-processing device for anodizing the die-casting and a drying device 1 for drying the oxidized die-casting, and the post-processing device (the post-processing device is Known technology, not too much description) is that the die casting is placed under the corresponding electrolyte and specific process conditions, and under the action of an external current, a layer of oxide film is formed on the surface of the die casting to improve the surface of the die casting. The physical properties of hardness and wear resistance; the drying device 1 is a dryer, which is a known technology and will not be described too much; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com