Fruit vinegar fermentation process suitable for high-volume fermentation tank

A fermentation process and fermentation tank technology, applied in the field of fermentation, can solve the problems of fermentation failure and inability to obtain fruit vinegar products, etc., and achieve the effect of reducing process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

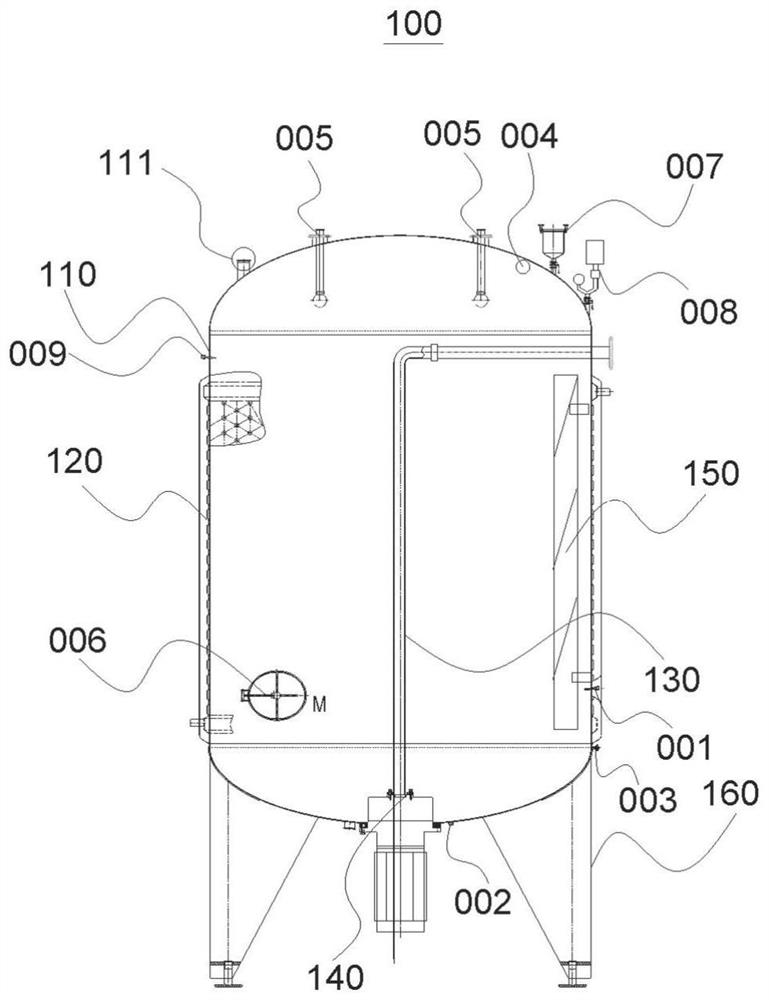

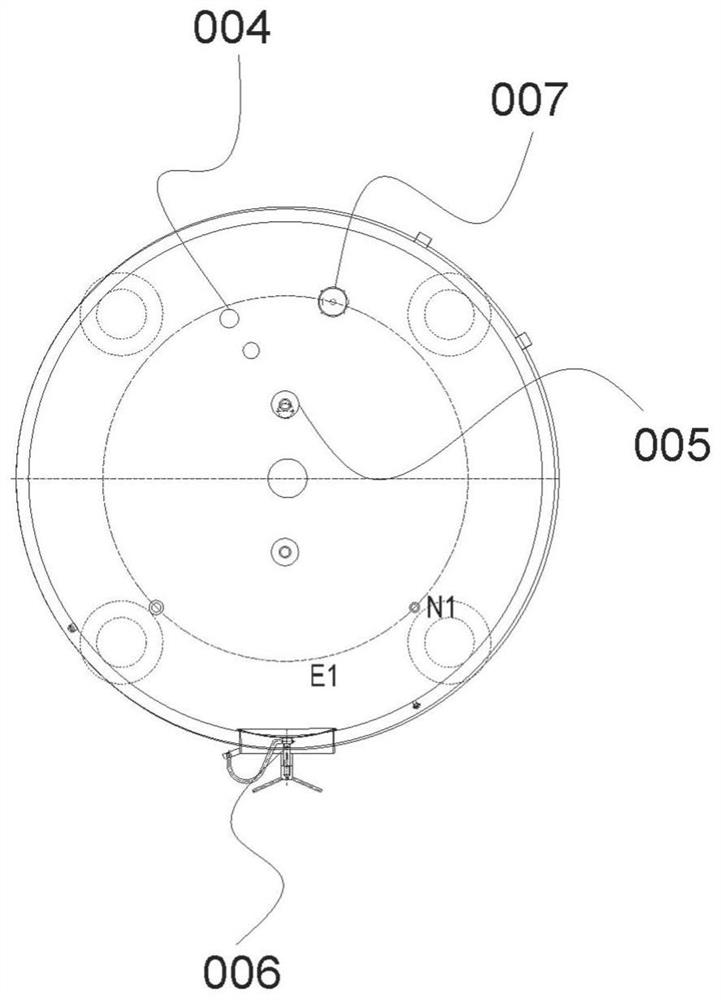

[0055] The present embodiment provides a kind of fruit vinegar fermentation technology that is applicable to large-capacity fermentation tank, adopts figure 1 with figure 2 The fermentation tank in carries out fermentation, comprises the steps:

[0056] Using wine vinegar with an alcohol content of about 0.6% vol and fruit wine with an alcohol content of about 9.1% vol as the mixed fermentation substrate, the acidity of the mixed fermentation substrate is controlled to be about 1.0g / 100mL, and the alcohol content is about 5.0% vol. Inoculate acetic acid bacteria to ferment, and the acetic acid bacteria seeds are derived from two different seed expansion tanks (one part adopts the expansion base material alcohol content to be 5.0%vol, soluble solids 4.6%, and another part adopts the expansion base material alcohol content to be 4.0% vol, 3.7% soluble solids, expansion temperature is 35°C, expansion transfer acidity is 2.5g / 100mL), the mass ratio of acetic acid bacteria liquid...

Embodiment 2

[0059] The present embodiment provides a kind of fruit vinegar fermentation technology that is applicable to large-capacity fermentation tank, adopts figure 1 The difference between the process route in Example 1 and Example 1 is that the fermentation process adopts a two-stage hierarchical oxygen ventilation method, and within the first 6 hours after the start of fermentation, the ventilation rate per hour is to control the volume ratio of air volume to fermentation mash to 7.0:1 , and then fermented to the end according to the volume ratio of 8.0:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com