Multifunctional feeding equipment for intelligent hot press

An intelligent hot press, multi-functional technology, applied in applications, conveyor objects, clothing, etc., can solve the problems of limited production and processing efficiency, slow processing progress, waste of manpower and material resources, etc., to improve production and processing efficiency and work efficiency , Guarantee the effect of processing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

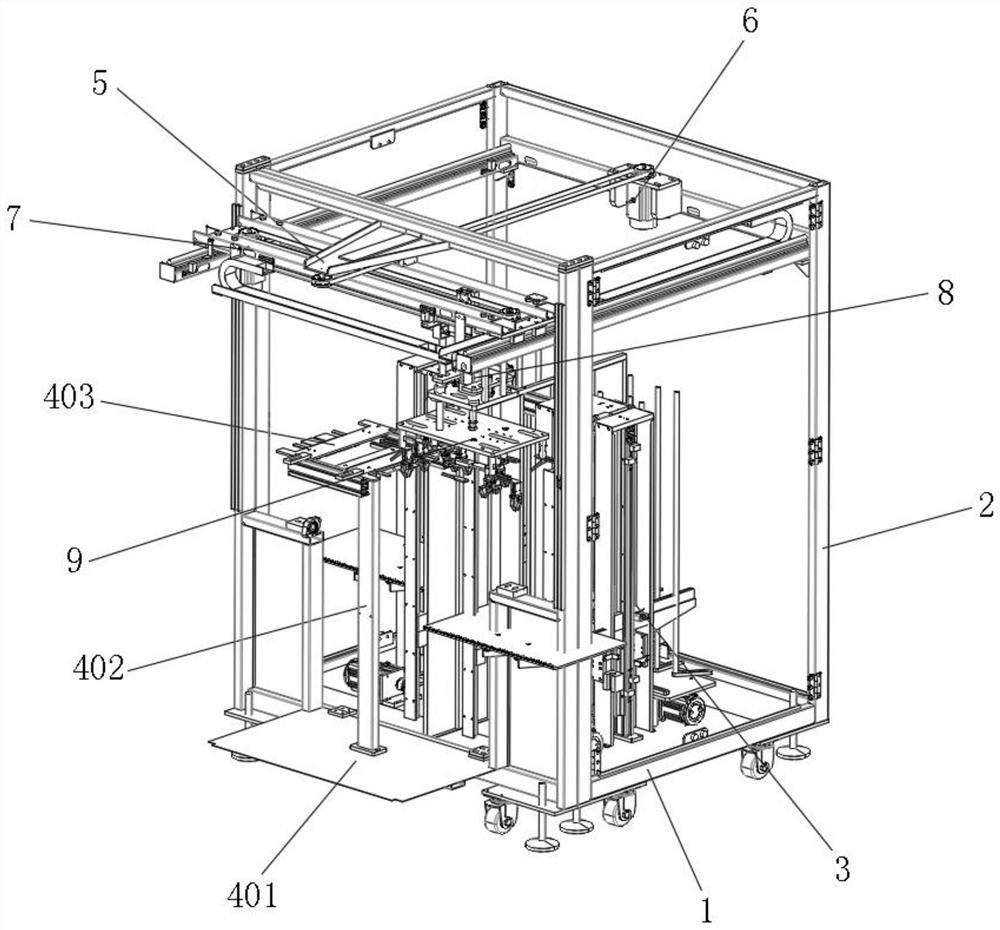

[0032] like Figure 1-2 As shown, the embodiment of the present invention provides a multi-functional upper device for a smart hot press, including a fixed bottom portion 1, and a 10,000-way wheel is installed at the corner of the bottom portion of the fixed bottom portion, and one side of the universal wheel is provided with support. The seat can be convenient to move the device, and can also be fixed at the specified position; the top of the fixed bottom portion 1 is fixedly connected to the external frame 2, and the center of the fixed bottom 1 is provided with a multi-station servo supply mechanism 3, fixed One side of the bottom 1 top is fixedly connected to the plastic platform 4.

[0033] like figure 1 As shown, the sheet 4 includes a support base 401 that supports the center of the support base 401 with a support column 402, and the top end of the support column 402 is fixedly connected to the material stacking platform 403.

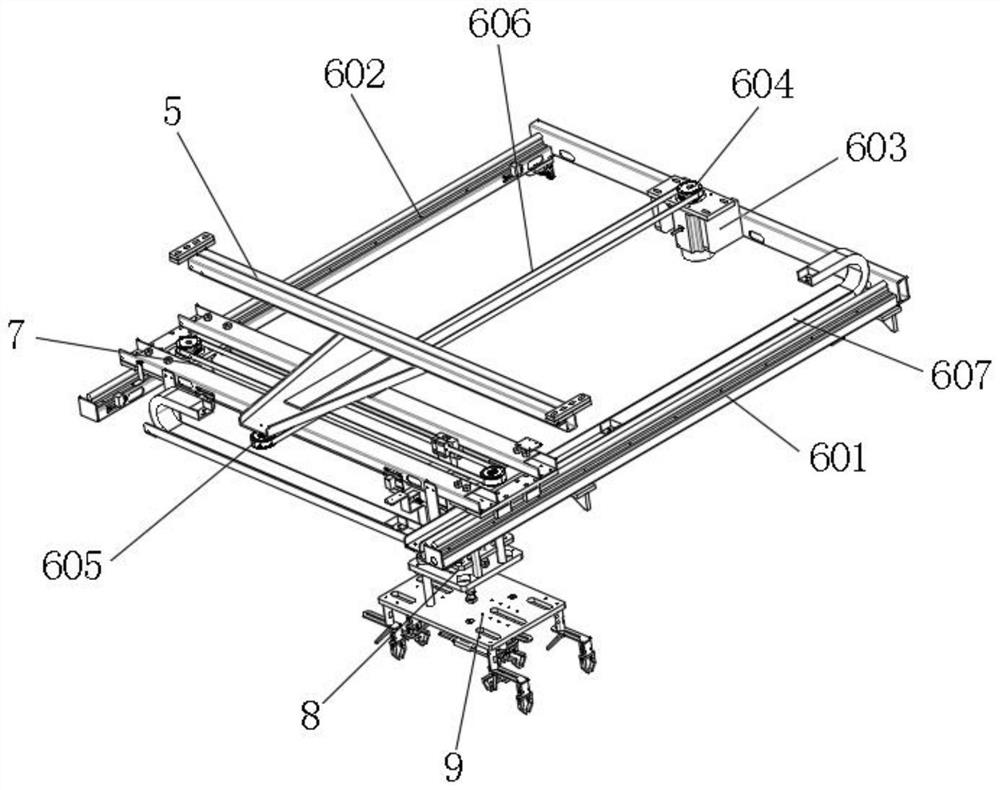

[0034] like image 3As shown, the top portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com