Distribution transformer energy efficiency metering detection equipment

A distribution transformer, measurement and detection technology, applied in the field of distribution transformers, can solve the problems of reducing the accuracy of energy efficiency measurement and detection, poor contact strength, data errors, etc., to ensure normal power on, avoid displacement, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

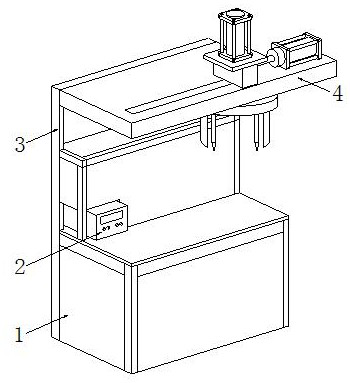

[0022] Append figure 1 Attachment Figure 5 Looking:

[0023] According to a distribution transformer energy efficiency measurement device, a structure includes a placing table 1, a electronically controlled box 2, a support frame 3, azimuth adjustment mechanism 4, and the placement stage 1 is mounted with an electronically controlled box 2, and place table The rear side end is welded to the lower end of the support frame 3, and the front end of the top end of the support frame 3 is attached, and the orientation adjustment mechanism 4 is located above the placement table 1, the orientation adjustment mechanism 4 including the support station 41, sliding The rail 42, the push frame 43, the first cylinder 44, the second cylinder 45, the detecting mechanism 46, the support station 41 is welded to the upper end of the support frame 3, and the support table 41 is provided with a rail 42, the push frame 43 lower end Sliding is mounted inside the rail 42, the first cylinder 44 output term...

Embodiment 2

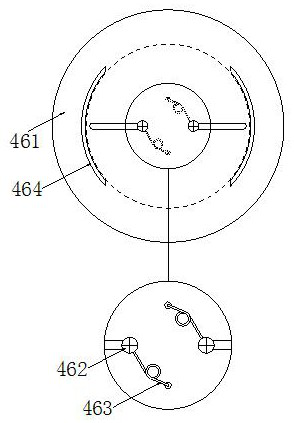

[0030] Append Image 6 Attachment Figure 7 Looking:

[0031]Wherein, the foreign matter 464 includes a bonding mechanism 64a, an extrusion slider 64b, a spring rail 64c, and the middle end of the bonding mechanism 64a is provided with a squeezing slider 64b, and the extrusion slider 64b slides mounted in the spring. The guide rail 64C is inside, the spring rail 64c is fixed to the inside of the link 461, and the extruded slider 64b and the spring guide rail 64c are provided with three, and is provided on the outer end and the middle end of the curved bonding mechanism 64a. It is conducive to the extrusion of the middle extrusion slider 64b in the middle of the transformer, thereby sliding the inner side on the outer side of the bonding mechanism 64a to automatically confut the outer surface of the transformer.

[0032] Wherein, the bonding mechanism 64a includes a picked sheet A1, an extruded ball A2, an insection of the tab A3, and an extruded ball A2 is embedded inside the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com