Supercritical carbon dioxide drying device

A drying device and carbon dioxide technology, applied in the direction of drying gas arrangement, drying solid materials, drying safety system, etc., can solve the problems that cannot be separated from professional technicians, rely on the experience of technicians, and require labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

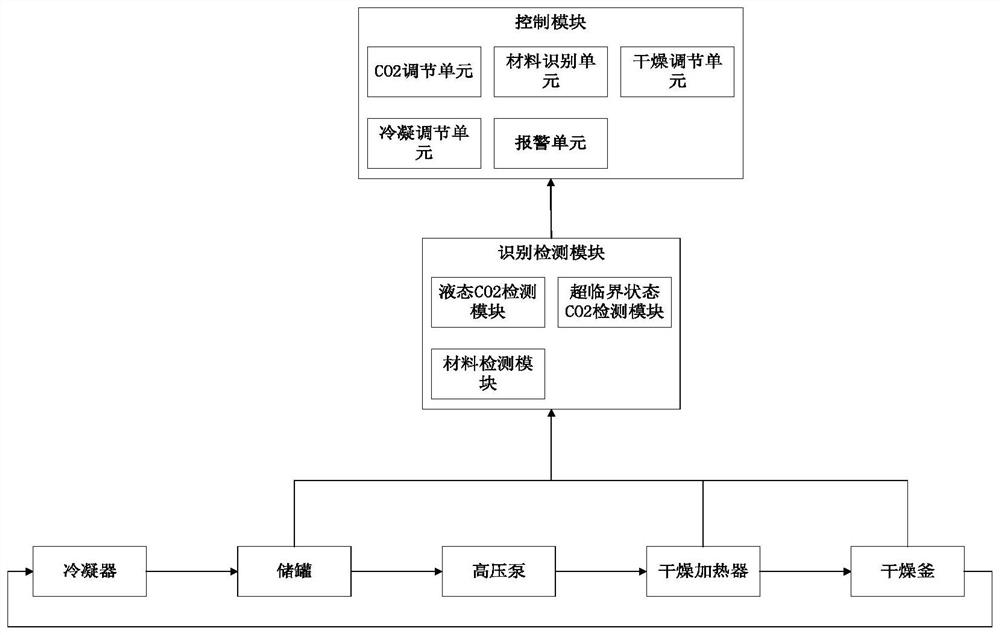

[0031] Such as figure 1 As shown, a supercritical carbon dioxide drying device according to an embodiment of the present invention includes a condenser 5, a storage tank 1, a high-pressure pump 2, a drying heater 3, a drying kettle 4, an identification and detection module, and a control module.

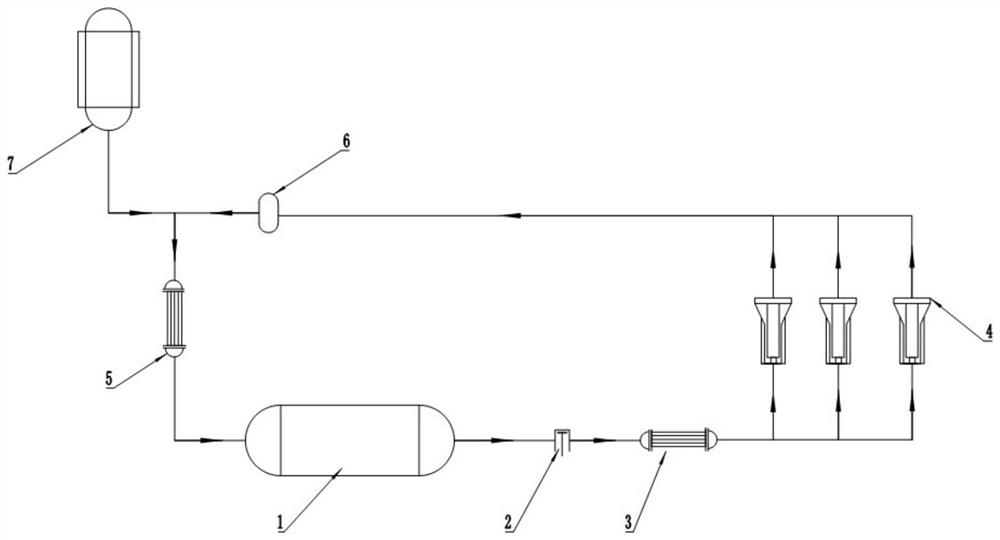

[0032] Such as figure 2 As shown, a kind of supercritical carbon dioxide drying device of the present embodiment, each component is connected in pipelines in sequence according to the order of the condenser 5, the storage tank 1, the high-pressure pump 2, the drying heater 3, and the drying kettle 4, and the drying kettle 4 of the present embodiment is There are three, and each drying tank 4 is connected in parallel, and the CO2 replenisher 7 is connected between the filter 6 and the condenser 5 through a pipeline. Each drying kettle 4 is provided with an automatic pressure regulating valve. When the pressure in the drying kettle 4 is excessive, the automatic pressure regulating va...

Embodiment 2

[0049] In addition to the content of the first embodiment, the second embodiment also includes:

[0050] The supercritical carbon dioxide drying device in this embodiment further includes a parameter analysis module, which is used to analyze whether the parameters adjusted by the supercritical carbon dioxide drying device are correct, and send the analysis result to the host.

[0051] The control module controls and adjusts the power and running time of the condenser 5, so that the pressure of the liquid CO2 in the storage tank 1 is about 9 MPa, and the temperature is about 20 degrees. Or control and adjust the pressure of the high-pressure pump 2 and the heating of the drying heater 3, so that the CO2 phase changes into a supercritical state. When encountering the situation that the control module cannot adjust the CO2 to the required state, it may be that the parameters of the drying device have not been adjusted in place, causing the control module to turn the condenser 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com