Automatic tunnel ditch cable trough construction rack

A technology for trench cable troughs and benches, applied in tunnels, tunnel linings, drainage and other directions, can solve problems such as affecting the geometry and line type of trenches, cable troughs, not being easy to fix the template, and reducing the quality of the project. Work efficiency and engineering quality, structure flatness and linear appearance, and the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

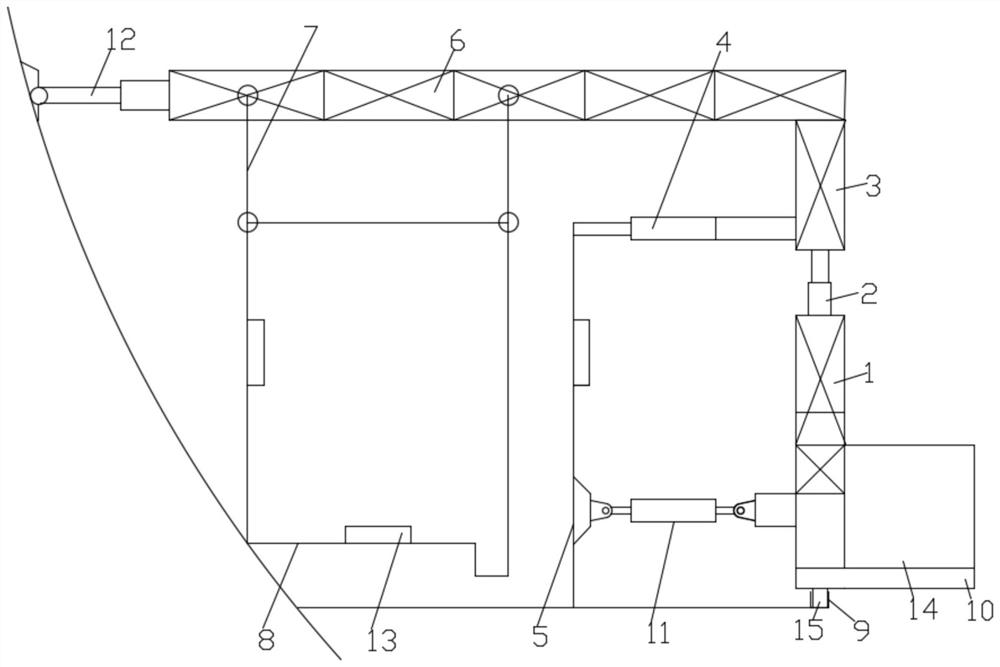

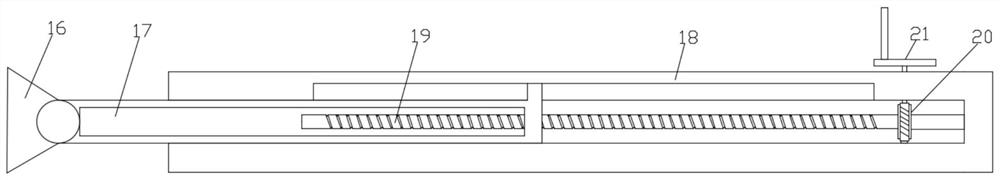

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

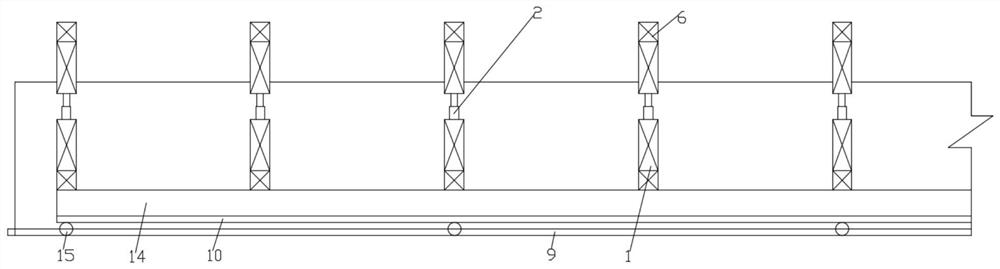

[0020] Please see attached Figure 1-2 , an automated tunnel ditch cable trough construction platform, including an underframe 1; two ends of the underframe 1 are respectively provided with a walking system and a first hydraulic rod 2, and the first hydraulic rod 2 is far away from the underframe 1 One end of the vertical support rod 3 is connected to the side wall of the vertical support rod 3, and the outer formwork 5 is installed through the second hydraulic rod 4, and the top of the vertical support rod 3 is connected to a horizontal support rod 6, and the horizontal support rod 6 A combined inner formwork 8 is installed on the support rod 6 through a suspender 7 .

[0021] The walking system includes a sliding rail 9 and a sliding seat 10 , the sliding seat 10 is connected with the chassis 1 , and the sliding seat 10 is slidably installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com