Multi-directional locking device for automatic lifting of container type freight transport system of civil aircraft

A civil aircraft, automatic lifting technology, applied to equipment for loading and unloading cargo, aircraft parts, building locks, etc., can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

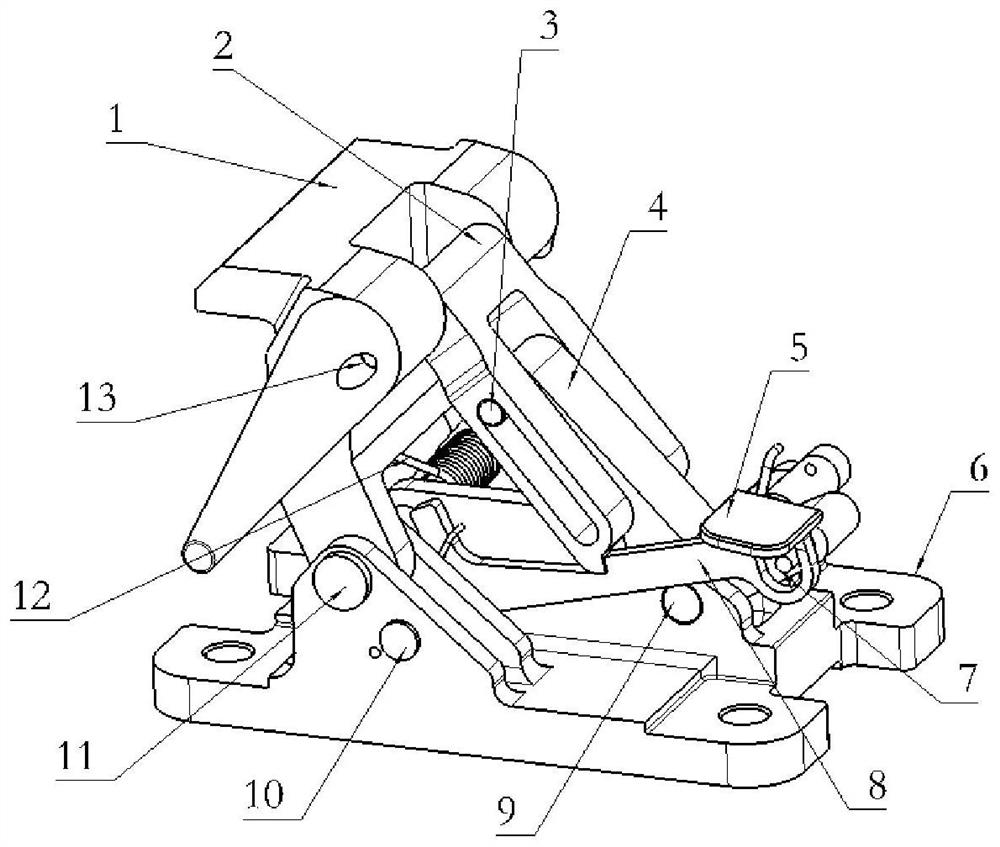

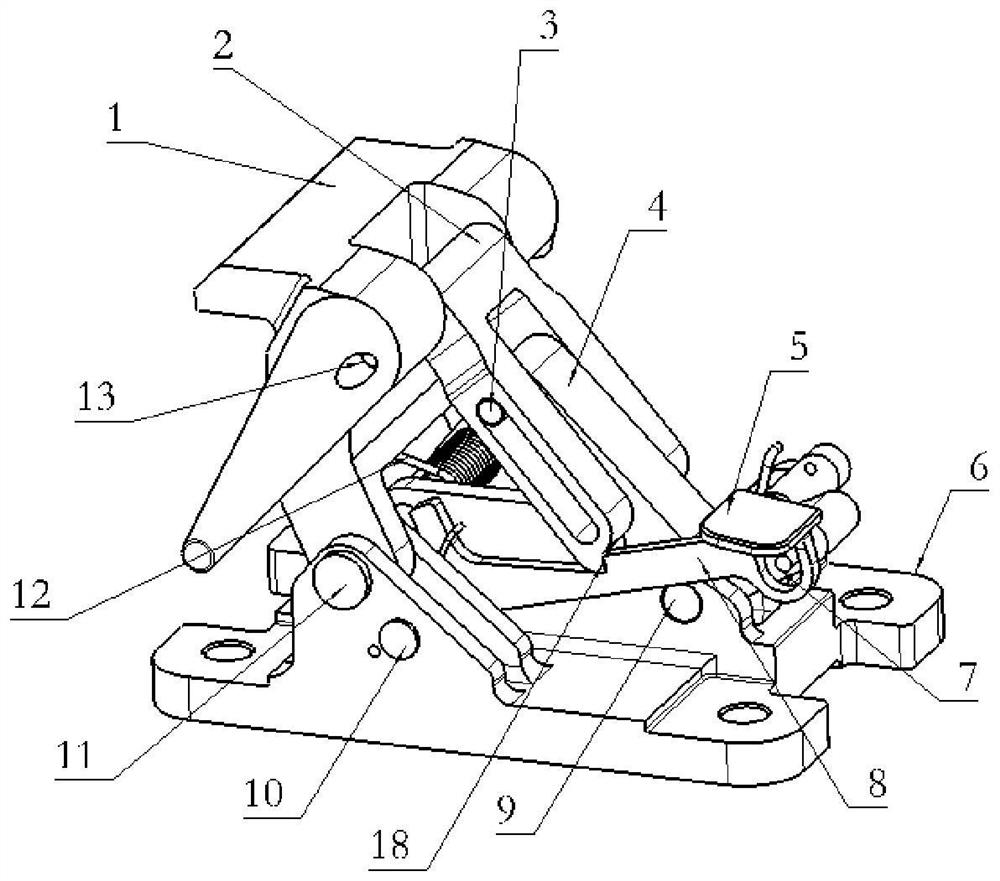

[0032] The present application will be described in further detail below through specific implementation methods and accompanying drawings.

[0033] The multi-directional locking device for the automatic lifting of the containerized cargo system of civil aircraft provided by the present invention includes: locking bolt 1, base 6, linkage lever 2, limit rotating arm 4 and unlocking rotating arm 8,

[0034] Wherein, the locking bolt 1 is located on the left side of the base 6, and the locking bolt 1 is connected to the base 6 through a hinge. The linkage rod 2 is located in the middle of the locking dead bolt 1, and the two ends of the linkage rod 2 are hingedly connected with the locking dead bolt 1 respectively.

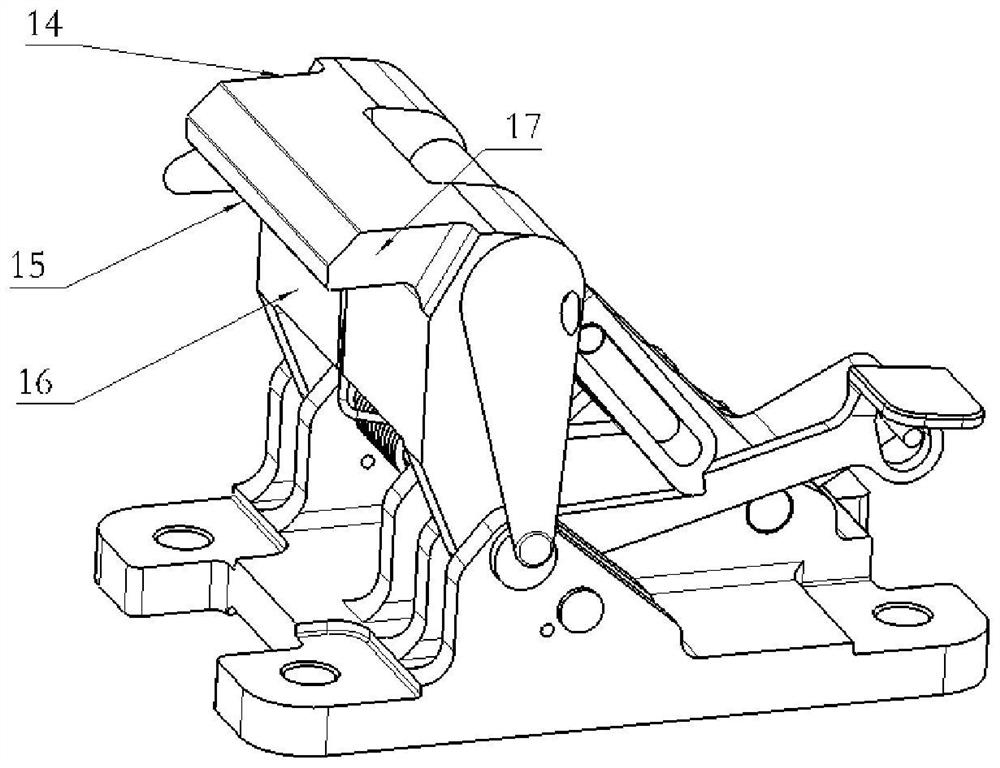

[0035] In the present invention, the locking bolt 1 has four limit surfaces, wherein the vertical limit surface 15 is located above the lock tongue, the course limit surface 14 and the reverse course limit surface 17 are located on both sides of the vertical limit su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com