Curve braking performance test pavement and construction method thereof

A construction method and a technology of curves, which are applied to the road surface of the curve braking performance test and its construction field, can solve problems such as adhesion to the road surface, reduced service life of the road surface of the curve braking performance test road, uneven cracks, etc., and achieve The effect of prolonging the service life, ensuring accuracy, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A construction method of a road surface for a braking performance test on a curve, comprising the following steps:

[0026] S1. Laying of lime-stabilized soil subbase:

[0027] 1. Measurement and stakeout: Restoring the center line on the top of the earthwork subgrade road bed, setting up a pile every 15-20m for the straight line section, and setting up a pile every 10-15m for the curved section, and setting instructions on the edges of the road shoulders on both sides: carry out horizontal measurement, Mark the design elevation of the cement-soil edge with obvious signs on the indicator pile.

[0028] 2. Transportation and paving of earthwork and lime: Sprinkle water to make the surface moist for the section of paving earthwork: When earthwork is loaded into trucks, the quantity of each truck should be controlled to be basically equal: on the top of the road bed, according to the calculated pile of soil for each truck Area, use lime lines to make grids to control unlo...

Embodiment 2

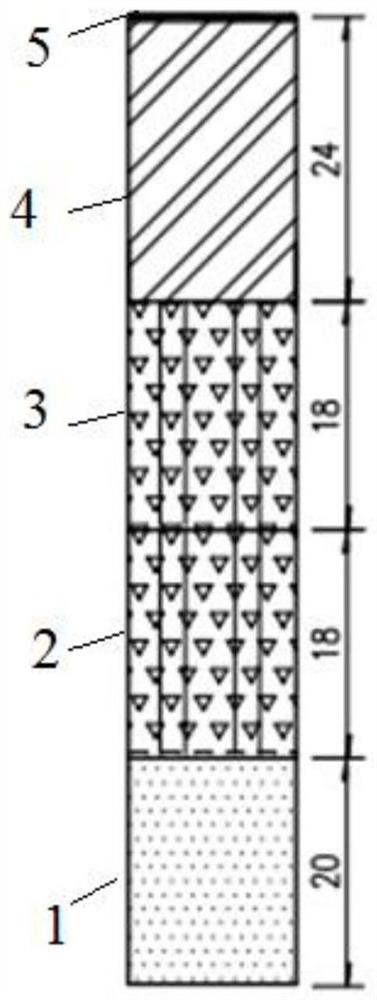

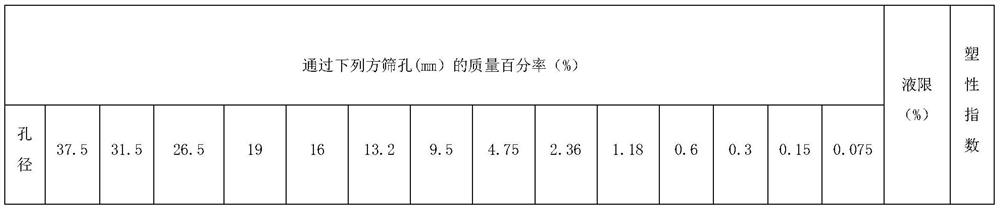

[0046] The present embodiment is carried out on the basis of Example 1, wherein, in step S1, in the laying process of the lime-stabilized soil sub-base, the content of lime in the lime-stabilized soil sub-base is 10%, and the height of the lime-stabilized soil sub-base is 20cm, in step S2, cement dose is 5% in the cement-stabilized gravel base course, (promptly all is gravel except cement, water, maximum particle diameter 31.5mm, maximum nominal particle diameter 26.5mm), laying thickness earlier is The first cement-stabilized macadam base of 18cm, the second cement-stabilized macadam base is laid after 7 days of maintenance, the thickness is 18cm, that is, the total thickness of the cement-stabilized macadam base is 36cm, and the maximum particle size of the base aggregate is not More than 31.5mm, the gradation composition of the aggregate is shown in Table 1 below.

[0047] Table 1

[0048]

[0049]

[0050] In step S3, the pouring thickness of the C35 cement concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com