Method for producing industrial phosphoric acid by wet-process phosphoric acid and co-producing ammonium polyphosphate or solid phosphoric acid

A technology of wet-process phosphoric acid and ammonium polyphosphate, applied in phosphoric acid, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of extraction stages, device energy consumption, stripping agent consumption increase, and phosphoric acid extraction efficiency. Improvement, without considering the influence of anions, etc., to achieve the effect of less impurities, high efficiency, and high phosphorus yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

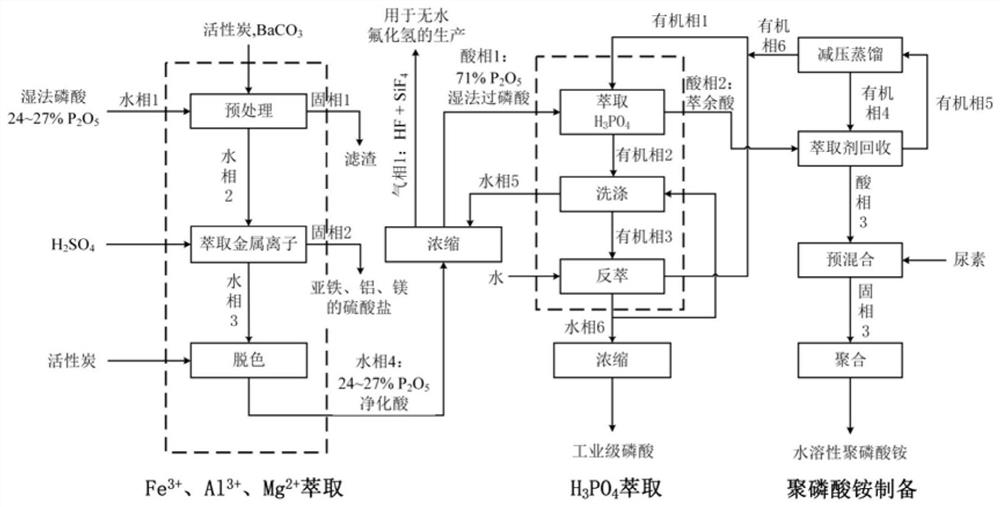

[0083] This embodiment provides a figure 1 The method for purifying high-concentration wet-process phosphoric acid shown, the method comprises the following steps:

[0084] The composition of the wet-process phosphoric acid (aqueous phase 1) selected in this example is shown in Table 1 below.

[0085] Table 1

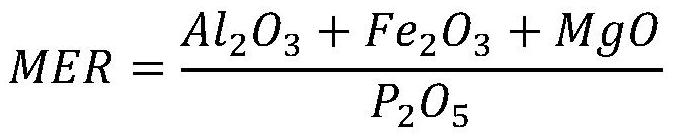

[0086] component Fe 2 O 3 / %

Al 2 O 3 / %

MgO / % P 2 O 5 / %

SO 3 / %

MER Content (wt%) 0.900 1.110 0.85 24.32 1.90 0.118

[0087] (1) Pretreatment: barium carbonate and activated carbon are simultaneously added to the wet-process phosphoric acid (aqueous phase 1), and the wet-process phosphoric acid is simultaneously desulfurized and decolorized. The specific operation is as follows: under normal pressure, keeping the temperature at 50° C., adding 130% of theoretical amount of barium carbonate and 1% of activated carbon by weight of phosphoric acid to the wet-process phosphoric acid, and reacting for 10 minutes. ...

Embodiment 2

[0106] This embodiment provides a figure 1 The method for purifying high-concentration wet-process phosphoric acid shown, the method comprises the following steps:

[0107] The wet-process phosphoric acid composition selected in this example is shown in Table 6 below.

[0108] Table 6

[0109] component Fe 2 O 3 / %

Al 2 O 3 / %

MgO / % P 2 O 5 / %

SO 3 / %

MER Content (wt%) 0.900 1.110 0.85 24.32 1.90 0.118

[0110] (1) Pretreatment: barium carbonate and activated carbon are simultaneously added to the wet-process phosphoric acid (aqueous phase 1), and the wet-process phosphoric acid is simultaneously desulfurized and decolorized. The specific operation is as follows: under normal pressure, keeping the temperature at 50° C., adding 130% of theoretical amount of barium carbonate and 1% of activated carbon by weight of phosphoric acid to the wet-process phosphoric acid, and reacting for 10 minutes. After the reaction was c...

Embodiment 3

[0129] This embodiment provides a figure 1 The method for purifying high-concentration wet-process phosphoric acid shown, the method comprises the following steps:

[0130] The composition of the wet-process phosphoric acid selected in this example is shown in Table 11 below.

[0131] Table 11

[0132] component Fe 2 O 3 / %

Al 2 O 3 / %

MgO / % P 2 O 5 / %

SO 3 / %

MER Content (wt%) 0.900 1.110 0.85 24.32 1.90 0.118

[0133] (1) Pretreatment: barium carbonate and activated carbon are simultaneously added to the wet-process phosphoric acid (aqueous phase 1), and the wet-process phosphoric acid is simultaneously desulfurized and decolorized. The specific operation is as follows: under normal pressure, keeping the temperature at 50° C., adding 130% of theoretical amount of barium carbonate and 1% of activated carbon by weight of phosphoric acid to the wet-process phosphoric acid, and reacting for 10 minutes. After the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com