Mold detection device and detection method

A detection device and detection method technology, which is applied in the field of mold detection, can solve problems such as lack of mold detection methods, difficulty in detecting ejection, reset actions, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

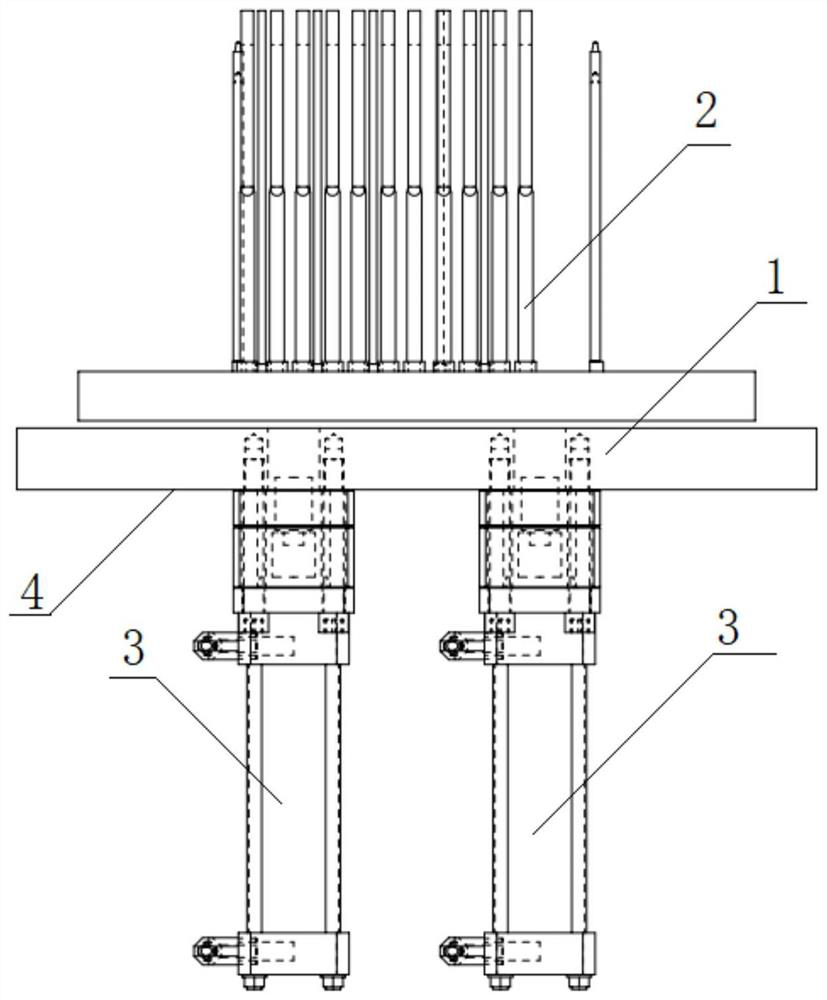

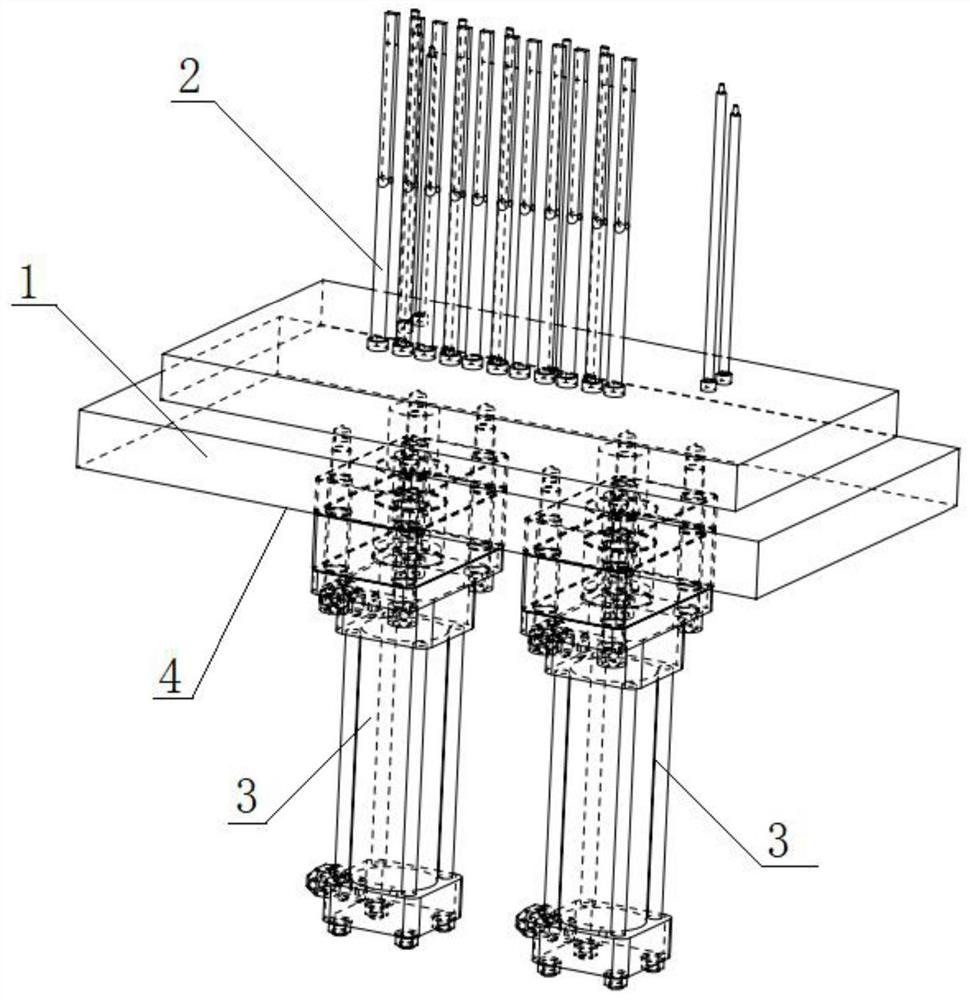

[0034] This embodiment provides a mold testing device, which includes a thimble bottom plate 1 on which a plurality of thimbles 2 are fixed and can move up and down. The mold is placed on the thimble 2 of the thimble bottom plate 1. After the thimble bottom plate 1 rises, it can drive the thimble 2 on it to rise, and the rising thimble 2 will touch the mold on it to be ejected; The thimble 2 descends, and finally the thimble 2 returns to the reset position. In fact, when testing whether the mold can be ejected and reset smoothly, it is possible to control the thimble bottom plate 1 to rise and fall repeatedly, so that the mold on it can continuously perform the ejection and reset actions, and then check the mold performance. Whether the ejection and reset actions are carried out smoothly and continuously.

[0035] In this embodiment, the hydraulic cylinder 3 is used to drive the thimble bottom plate 1 to move up and down. The hydraulic cylinder is used to drive the lifting m...

Embodiment 2

[0041] This embodiment provides a mold ejection and reset detection device on the basis of the above-mentioned embodiments. The setting positions of the hydraulic cylinder 3, the thimble bottom plate 1, and the thimble 2 of the mold detection device provided in this embodiment are the same as those in Embodiment 1. The scheme is the same. This embodiment also provides a detection device for detecting whether the movement of the mold is smooth during continuous ejection and reset by means of image collection.

[0042] Specifically, the mold ejection and reset detection device provided in this embodiment includes:

[0043] The display processor collects images of continuous ejection and reset actions of the mold, and can analyze the above-mentioned images collected by it, so as to judge whether the continuous ejection and reset actions of the mold are smooth by using the analysis of the above-mentioned images.

[0044] The cloud display system displays the images of the continu...

Embodiment 3

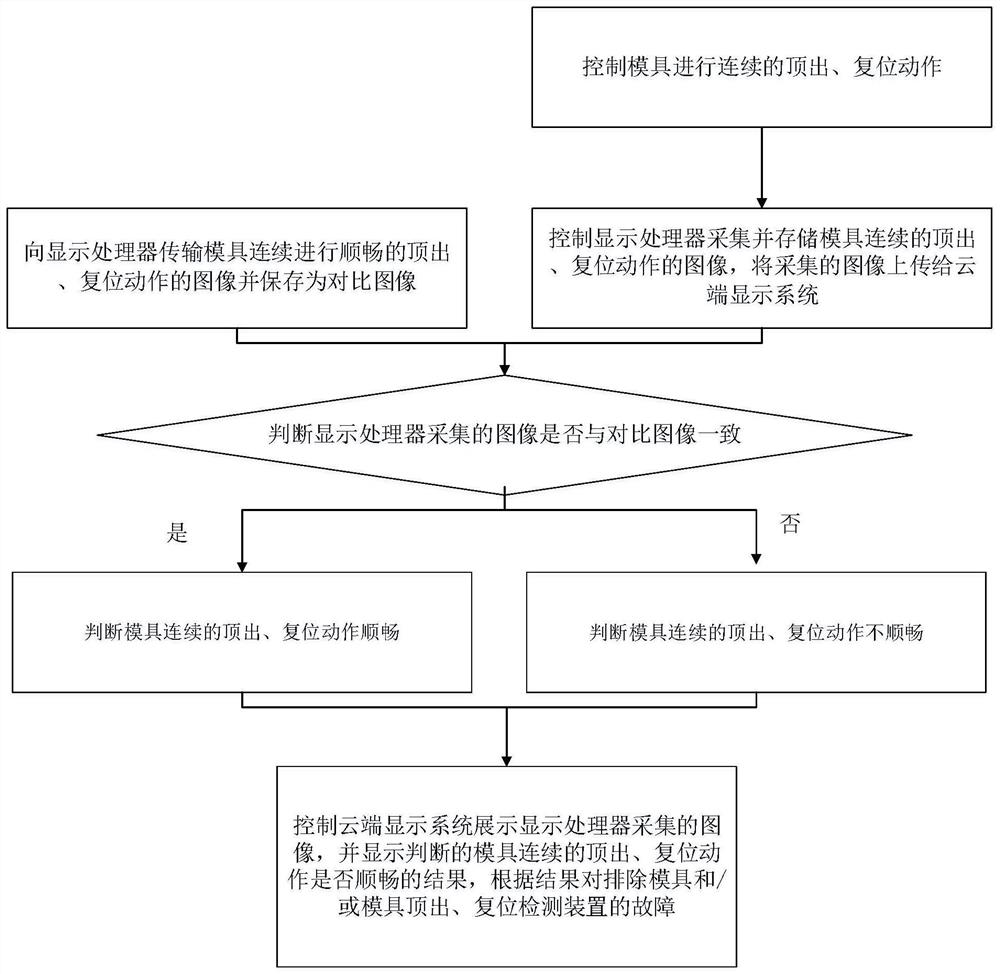

[0049] This embodiment provides a mold detection method on the basis of the above embodiments, and the mold detection method provided by this embodiment can be used in the mold detection device of the above embodiment. The detection method of the mold provided in this embodiment mainly detects whether the continuous ejection and reset actions of the mold are smooth through image comparison.

[0050] The detection method of the mold that present embodiment provides, as image 3 As shown in , it includes first controlling the mold to perform continuous ejection and reset actions.

[0051] Afterwards, the control display processor collects and stores the images of the continuous ejection and reset actions of the mold, and uses the collected images of the continuous ejection and reset actions of the mold to judge whether the continuous ejection and reset actions of the mold are smooth. The display processor uploads the collected images of the continuous ejection and reset actions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com