Reflow soldering device of low-loss Schottky rectifier tube

A technology of reflow soldering and rectifier tube, which is applied to electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of weak adjustment ability of fixed circuit board devices, inability to adapt to the fixed installation process of circuit boards, and energy waste of reflow soldering equipment. Achieve the effect of increasing the processing range, good bearing effect, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

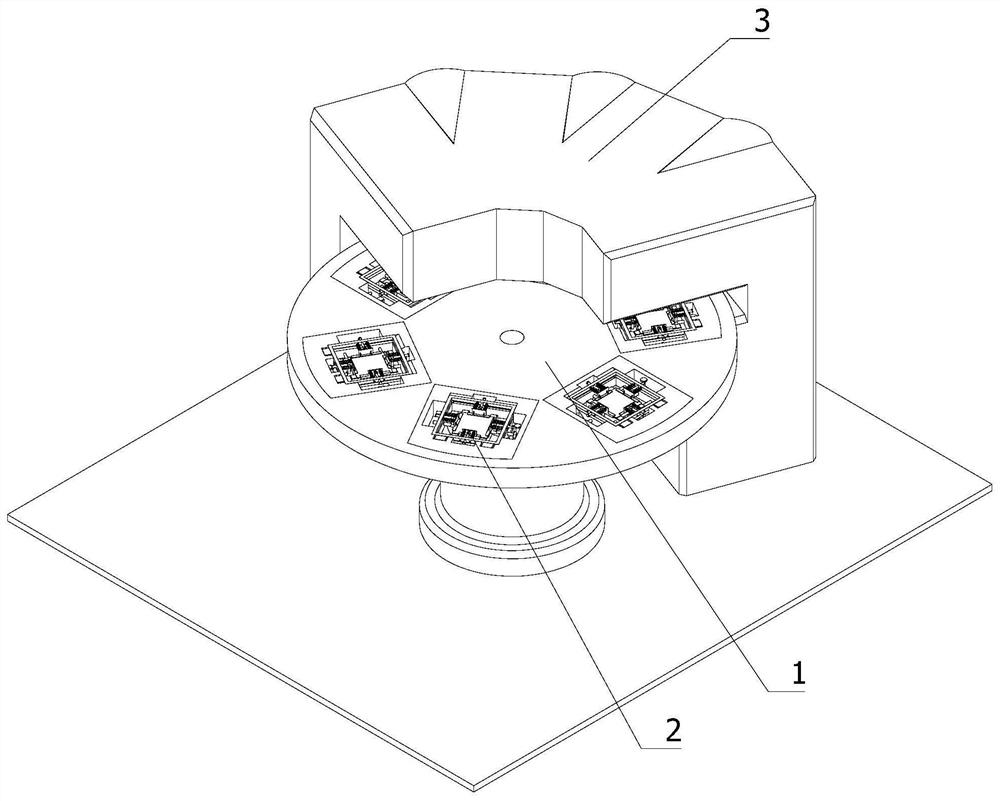

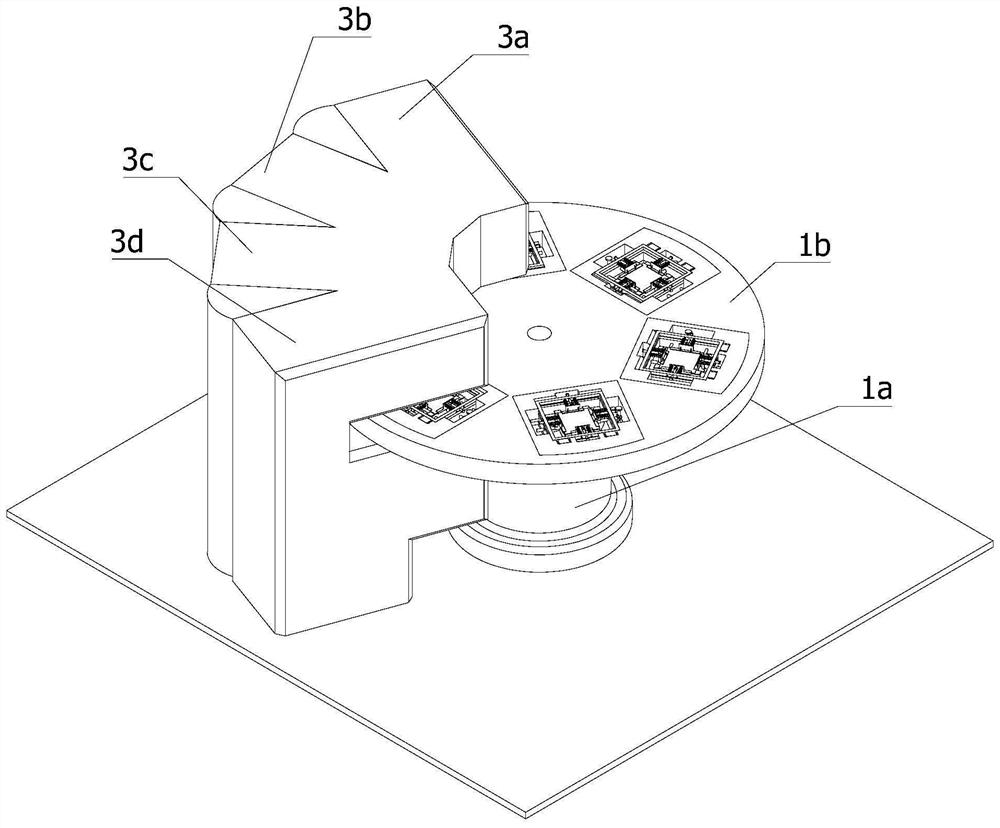

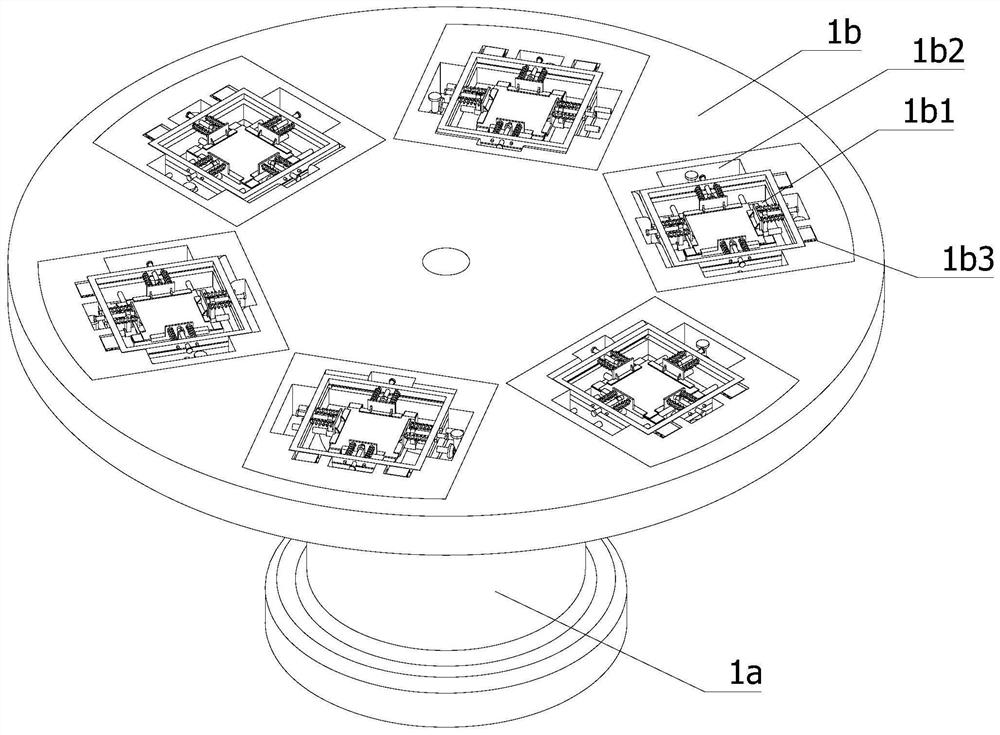

[0037] Such as Figure 1-4 Shown:

[0038] A reflow soldering device for a low-loss Schottky rectifier tube, including a circuit board, a frame and a continuous conveying mechanism 1 located above the frame, a positioning and clamping mechanism 2 and a reflow soldering mechanism 3, and the continuous conveying mechanism 1 It is fixedly installed on the frame, and the reflow soldering mechanism 3 is arranged on the frame. The continuous conveying mechanism 1 includes a turntable 1a and a working platform 1b. The working platform 1b is fixedly installed on the turntable 1a horizontally. To install the through-mounting opening 1b1 of the positioning and clamping mechanism 2, several through-mounting open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com