Method for improving lactic acid in silage, and mixed silage process

A kind of silage material and process technology, which is applied in the mixed silage process of rice straw and coix coix to increase the lactic acid field of silage material. It can solve the problems of unsuitable operation and inconvenient operation for farmers, so as to simplify the silage operation process and operation difficulty, and solve the problem of difficult storage, The effect of high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

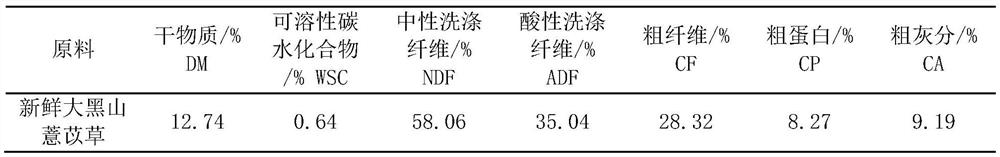

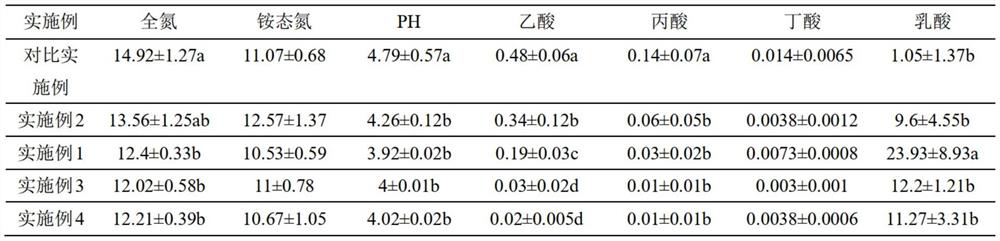

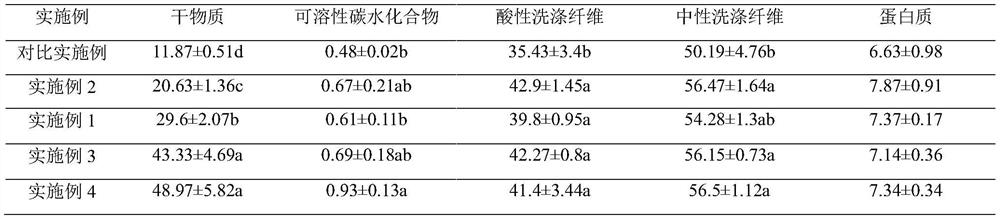

[0022] Example 1. A mixed silage process of rice straw and Daheishan Coix coix, the steps include: cutting off the roots of the harvested fresh straw and then drying, controlling the moisture content of the dried straw to 11.5±0.2%, kneading the dried straw with a kneading machine Shredded and cut into segments with a length of 3±0.5cm and a width of 1-3mm; remove the fresh Daheishan Coix coix and cut it into segments with a length of 3-5cm. Moisture control is 88 ± 2%; Gained straw segment is mixed with the gained Daheishan Coix segment according to the weight ratio of 2:8, and mixed thoroughly to obtain a mixture; the gained mixture is placed in a silage container, and the compacted density is 630kg / m 3 , and carry out vacuum treatment, and immediately package after vacuum; put the packaged silage in a cool environment with a temperature of 10-18° C. to ferment for 60 days.

Embodiment 2

[0023] Example 2. A mixed silage process of rice straw and Daheishan Coix coix, the steps include: cutting off the roots of the harvested fresh straw and then drying, controlling the moisture content of the dried straw to 11.5±0.2%, kneading the dried straw with a kneading machine Shredded and cut into segments with a length of 3±0.5cm and a width of 1-3mm; remove the fresh Daheishan Coix coix and cut it into segments with a length of 3-5cm. Moisture control is 88 ± 2%; Gained straw segment is mixed with the gained Daheishan coix segment according to the weight ratio of 1:9, and mixed thoroughly to obtain a mixture; the gained mixture is placed in a silage container, and the compacted density is 630kg / m 3 , and carry out vacuum treatment, and immediately package after vacuum; put the packaged silage in a cool environment with a temperature of 10-18° C. to ferment for 60 days.

Embodiment 3

[0024] Example 3. A mixed silage process of rice straw and Daheishan Coix coix, the steps include: cutting off the roots of the harvested fresh straw and then drying, controlling the moisture content of the dried straw to 11.5±0.2%, kneading the dried straw with a kneading machine Shredded and cut into segments with a length of 3±0.5cm and a width of 1-3mm; remove the fresh Daheishan Coix coix and cut it into segments with a length of 3-5cm. Moisture control is 88 ± 2%; Gained rice straw segment is mixed with gained Daheishan Coix coix segment according to the weight ratio of 3:7, mixes well, obtains mixture; Gained mixture is placed in the silage container, and the compaction density is 630kg / m 3 , and carry out vacuum treatment, and immediately package after vacuum; put the packaged silage in a cool environment with a temperature of 10-18° C. to ferment for 60 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com