Industrial automatic control system cabinet

An automatic control system and industrial technology, which is applied in the direction of electrical components, substation/distribution device casing, substation/switchgear cooling/ventilation, etc. Performance and other issues to achieve the effect of reducing the impact of climate, accelerating heat dissipation, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

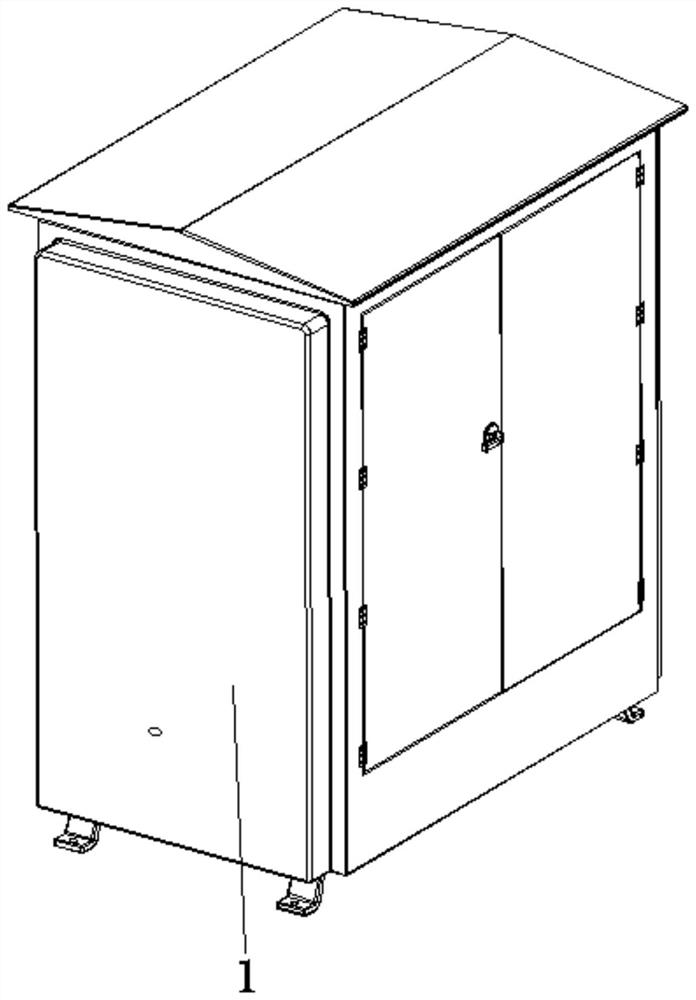

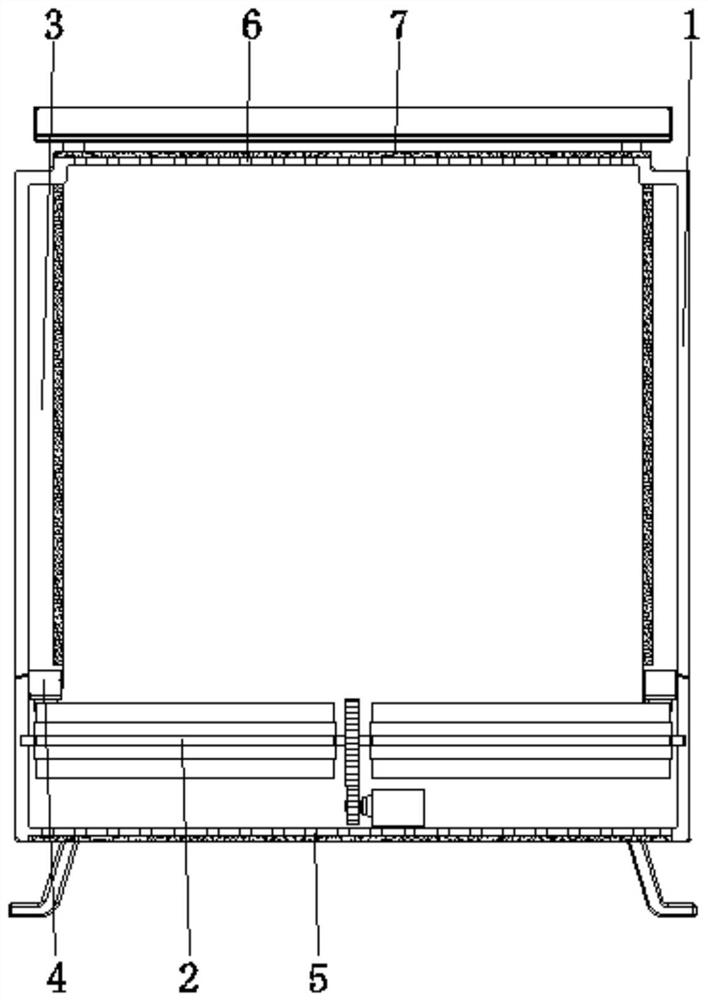

[0031] see Figure 1-7 , the present invention provides a technical solution: an industrial automatic control system cabinet, including a cabinet body 1, the interior of the cabinet body 1 is provided with a heat dissipation device 2, a suction device 3, a pressing device 4, an air inlet hole 5, and an air outlet hole 6 , dust filter screen 7, heat dissipation device 2 is rotatably connected between the two sides corresponding to the inner wall of cabinet body 1 and near the bottom position, suction device 3 is arranged on the inner wall of cabinet body 1, pressing device 4 is arranged on the inner wall of cabinet body 1 and Located at the bottom of the suction device 3, the air inlet hole 5 is set at the bottom of the cabinet body 1, the air outlet hole 6 is set at the top of the cabinet body 1, and the dust filter 7 is set at the top and bottom of the cabinet body 1 and located at the air inlet hole 5. The position of the air outlet 6 can reduce the dust from entering the in...

Embodiment example 2

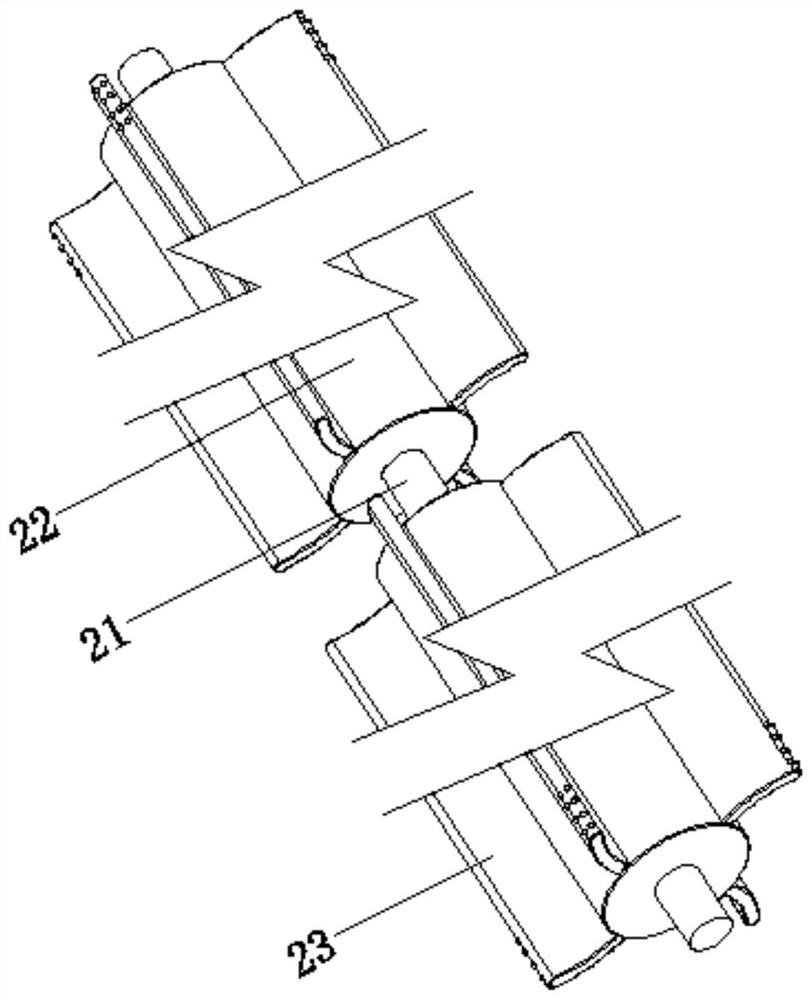

[0033] The cooling device 2 is provided with a rotating shaft 21, a drum 22, and a fan blade device 23. The two ends of the rotating shaft 21 are rotationally connected to the two sides corresponding to the inner wall of the cabinet body 1. The drum 22 is fixedly connected to the surface of the rotating shaft 21 and is close to the end position. The device 23 is fixed on the surface of the drum 22, and the end of the fan blade device 23 is connected with the bottom of the pressing device 4. After the rotating shaft 21 is driven by the motor, the drum 22 drives the fan blade device 23 to rotate, and the blade device 23 is rotated in time. The air inside the cabinet 1 is instigated, and through the flow of gas, the heat is dissipated from the air outlet 6, and at the same time, the external cold air enters from the air inlet 5, thus forming an air convection cycle, which accelerates the heat dissipation. It reduces the occurrence of high temperature, accelerates evaporation, and ...

Embodiment example 3

[0036] The suction device 3 is provided with a base plate 31, a water-absorbing sponge body 32, a main channel 33, and a horn hole 34. One side of the surface of the base plate 31 is fixedly connected with the inner wall of the cabinet body 1, and the water-absorbing sponge body 32 is arranged on the surface of the base plate 31 and is far away from the cabinet body. 1, the main channel 33 is opened inside the base plate 31, the bottom end of the main channel 33 is connected with the pressing device 4, the horn hole 34 is opened on the inner wall of the base plate 31 and is located at the position of the water-absorbing sponge body 32 and is connected with the The main channel 33 is connected, and the water-absorbing sponge body 32 can absorb the condensation and water droplets in the cabinet 1 in time, and reduce the rotation of the fan blade device 23, so that the pressing device 4 can work. The water on the water-absorbing sponge body 32 is quickly absorbed from the horn hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com