Prediction method for safety assessment of coal mill

A forecasting method and coal mill technology, applied in forecasting, machine learning, computer parts, etc., can solve the problems of unfavorable construction of economical power plants, inability to fully realize the safety assessment of coal mill equipment, high cost and other problems , to achieve the effect of being scientific and rigorous, shortening the variable dimension of the original data matrix, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

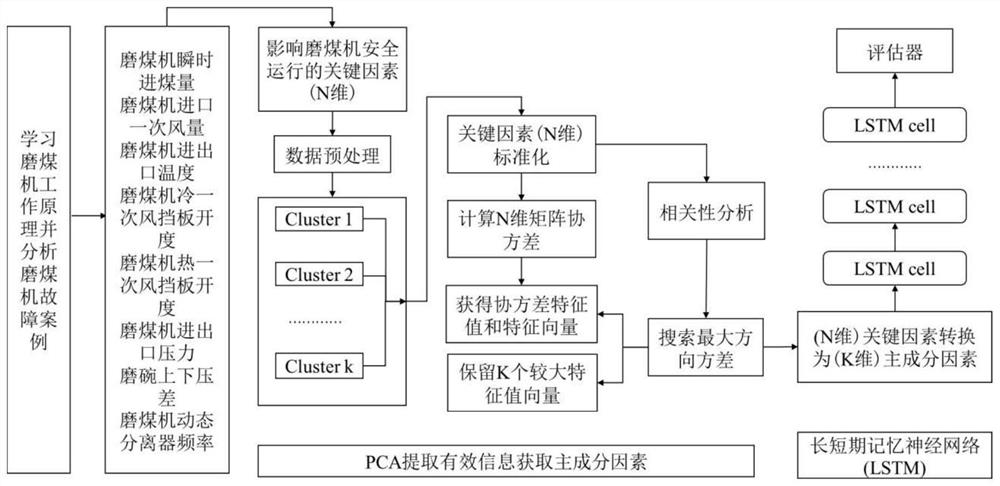

[0049] A prediction method for the safety assessment of coal mills in this application can be referred to figure 1 Flowchart, including the following steps:

[0050]S1. Extract the key factor variables and their corresponding expert scores that affect the safe operation of the coal mill equipment from the historical operation database to form the original data set;

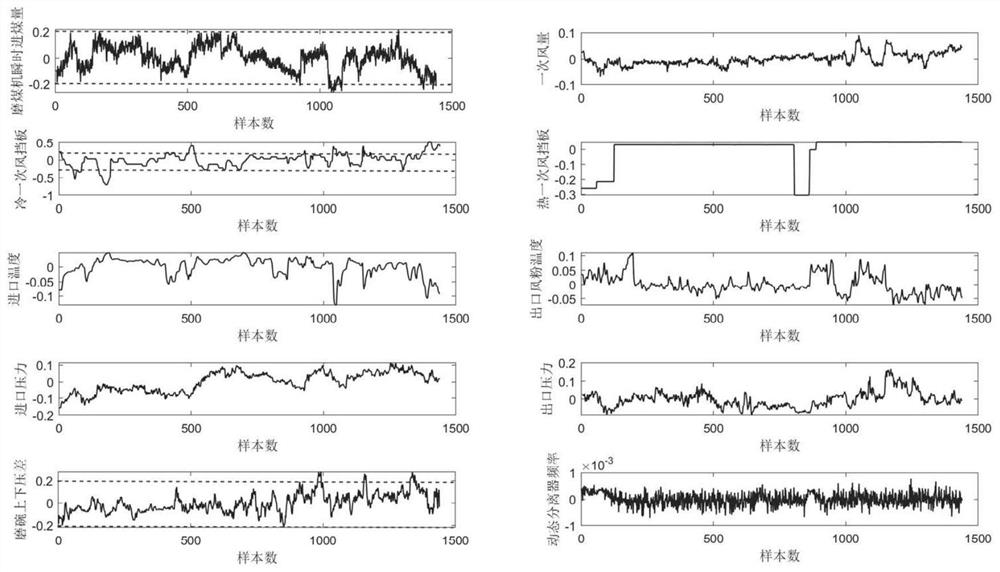

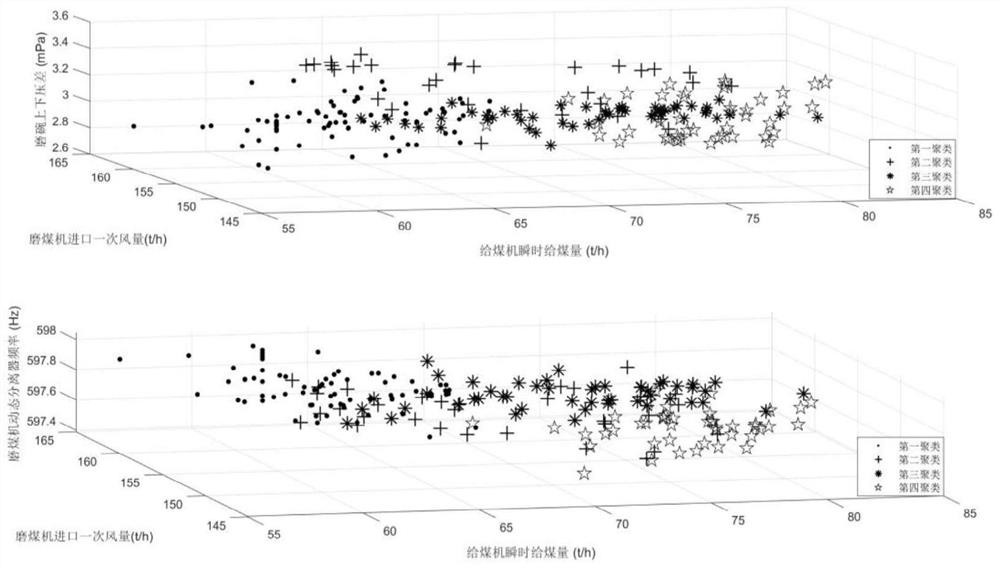

[0051] Specifically, the key factors that affect the safe operation of the coal mill equipment are identified based on the working principle of the coal mill and the failure cases of the coal mill, and the corresponding variables and corresponding expert scores are extracted from the historical operation database. The sampling period is once every minute. The short load is 350MW-400MW, which constitutes the original data set (original matrix) that affects the safety of coal mill equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com